Igama leProjekthi: Ithala leencwadi elizenzekelayo le-stereoscopic (njenge/rs)

Ixesha lokuqalisa kweprojekthi: ekuqaleni kuka-Epreli 2022

Ixesha lokugqitywa kweprojekthi: phakathi kukaJuni ngo-2022

Indawo yolwakhiwo lweprojekthi: Yancheng, Jiangsu, East China

Iqabane leprojekthi: ibhetri entsha yokuvelisa i-Co., Ltd. eYancheng, eJiangsu

Imfuno yabathengi: ishishini yinkampani entsha yokwenza ibhetri yamandla. Indawo yokugcina impahla yenkampani isetyenziselwa ikakhulu ukugcina ezinye izinto ezifunekayo ukwenza iibhetri ze-lithium kunye nezinye izinto zokubumba. Inkqubo yokuvelisa iibhetri ze-lithium inzima kwaye idinga izinto ezininzi, oku kuthetha ukuba ukusetyenziswa komsebenzi wezandla kufuna umsebenzi omningi, kwaye ukusebenza kakuhle komsebenzi wezandla akukwazi ukuhlangabezana nemigangatho yeshishini. Kule nkalo, ukwenzela ukuba kuphuculwe imeko yangaphakathi yendawo yokugcina impahla kunye nokunciphisa abasebenzi kwi-warehouse kangangoko kunokwenzeka, ukuze kuncitshiswe iindleko zeshishini, umthengi ufumene iimveliso zethu ze-Hebei Walker metal Co., Ltd. (i-brand ezimeleyo: i-hegris hegerls) kwaye sinethemba lokuba inkampani yethu inokubonelela ngeenkonzo zokugcinwa kwendawo enye yokumisa ezifana noyilo, ukwakhiwa, ukuveliswa, ukuveliswa kunye nokwakhiwa kwendawo yokugcina impahla yenkampani ngokweemfuno zabo.

Ukuphunyezwa kweprojekthi: umthengi wayenombono osisiseko kunye nesikhokelo xa befumana inkampani yethu. Emva konxibelelwano nenkampani yethu, kwaye ukuze kuhlangatyezwane nemigangatho elindelwe ngumthengi kangangoko kunokwenzeka, inkampani yethu yalungiselela amagcisa aqeqeshiweyo ukuba atyelele enye inkampani. Emva kophando, safumanisa ukuba inkampani inenani elikhulu lezinto eziphathekayo kunye nendawo yokugcina impahla. Ukuze kuncitshiswe ngcono ukusetyenziswa kwabasebenzi, ekugqibeleni saphuhlisa iskimu soyilo esicacileyo. Isikimu siphelele ngolu hlobo lulandelayo: ithala leencwadi elikrelekrele elizisebenzelayo lilonke lifuna ukuseka amathala eencwadi amane, angala, ithala leencwadi leplatinam, ithala leencwadi lezakhiwo, ithala leencwadi lokuzikhuphela ngokwalo kunye nethala leencwadi lovavanyo. Ithala leencwadi lezakhiwo kufuneka liyilwe kwaye lakhiwe njengamatonela amane, kwaye ithala leencwadi leplatinam kufuneka lisebenzise iitonela ezimbini. Kwangaxeshanye, xa siqwalasela ubungakanani bendawo yokugcina impahla, inkampani yethu icwangcise ukusebenzisa amaqela amaninzi eeshelufu eziphakamileyo eziphakamileyo, ii-stacker ezininzi ezinamacala amathathu athatha nokubeka iinkqubo, iinkqubo zokuphatha ngokuzenzekelayo ze-AGV kunye nezinye izixhobo zokugcina ezixhasayo kunye nezibonelelo, ngoko ke. ukuqinisekisa ukuba indawo yokugcina impahla inokwandisa ukusetyenziswa kwayo kwendawo.

Isishwankathelo seprojekthi: njenge/rs yiprojekthi enkulu kakhulu, kwaye iimfuno zeenkcukacha ekufakeni nazo zingqongqo kakhulu. Ukusukela ekuqaleni kofakelo ukuya kugunyaziso lwamva, amagcisa ethu ngokobuqu anoxanduva lokulandelela kunye nokuhlola iprojekthi ye-as/rs yethala leencwadi elinobukrelekrele elizisebenzelayo elinamacala amathathu ngaphezulu kweenyanga ezimbini. Okwangoku, sele isetyenziswe ngokusemthethweni kwaye yagqitywa ngempumelelo ukwamkelwa. Ngexesha elifanayo, lifumene ukwaneliseka okuphezulu kakhulu kumava omthengi kamva.

Inkqubo yokuphunyezwa kweprojekthi:

Ngokukhula okugqabhukileyo kweshishini elitsha lamandla, imfuno yeebhetri zamandla amatsha iyenyuka, kwaye iindleko kunye neemfuno zokusebenza nazo ziyenyuka. Ishishini elitsha lamandla lizele ngamathuba kunye nemingeni. Ngokukodwa, iqondo lokuzenzekelayo kunye nobukrelekrele bemigca yokuvelisa ibhetri imisela ngokuthe ngqo ukukhuphisana kwamashishini amandla amatsha. Ke ngoko, ukuphuculwa kwezixhobo ezizenzekelayo kube yeyona ndlela yokuphucula ukhuphiswano lwamashishini amatsha amandla. Ngoku ishishini liphuhlisa kwicala lokhuseleko kunye nomgangatho. Ukuchaneka okuphezulu, ukusebenza kakuhle okuphezulu, ukulandelelana kunye nemigca ephezulu yokuvelisa izixhobo ezizenzekelayo ziye zaba ngumkhombandlela jikelele wophuhliso. Izixhobo zokuvelisa ezizenzekelayo kunye nezikrelekrele ziya kuqinisekisa ukuhambelana okuphezulu, ukuthembeka okuphezulu, ukhuseleko kunye nokuthe ngqo ngesivuno seemveliso ngesiseko sokuqinisekisa inkqubo yemveliso, ukuze kuphuculwe izibonelelo ezibanzi zeshishini. Phakathi kwabo, i-automated warehouse ene-dimensional three-dimensional, njengesixhobo sezinto zanamhlanje, ngokungathandabuzekiyo idlala indima ebalulekileyo ekuphuculeni umgangatho wokugcinwa kwe-automation yamashishini. Kanye ngale ndlela, iHebei hegris hegerls warehouse icebisa ukuba kusetyenziswe indawo yokugcina izinto enobukrelekrele obunemigangatho emithathu ngokweemfuno zabathengi eYancheng, eJiangsu!

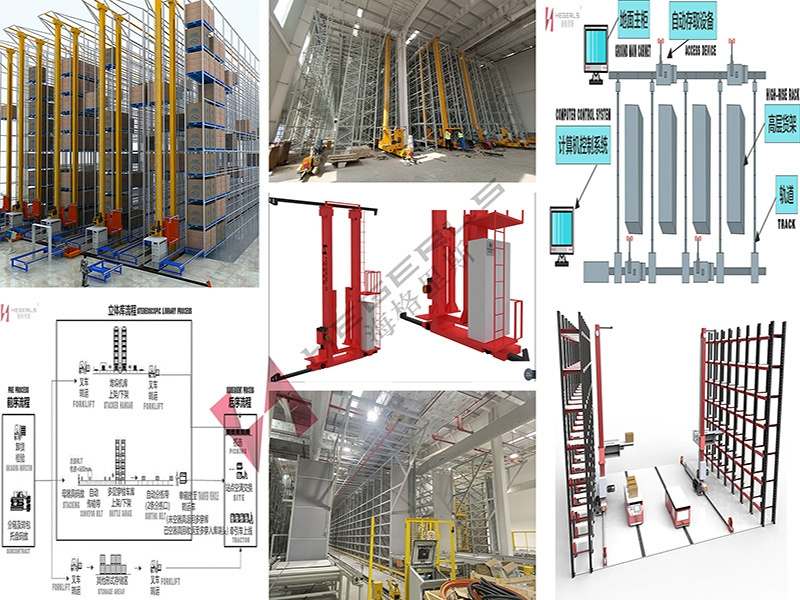

Ithala leencwadi lestereo elizenzekelayo njenge/rs umsebenzi

Indawo yokugcina i-stereoscopic e-Intelligent automatic as/rs inokugcina iindidi ezahlukeneyo zemathiriyeli ngokufanelekileyo nangengqiqo phantsi komyalelo ophezulu wenkqubo yolawulo lwekhompyutha; Ukubonelela zonke izinto kuwo onke amasebe ngokuchanekileyo, ngexesha lokwenyani kunye nokuguquguquka, kwaye unike ulwazi oluchanekileyo lokuthengwa kwezinto eziphathekayo, ukucwangciswa kwemveliso, ukucwangcisa, imveliso kunye noqhagamshelwano lwentengiso, njl. Kwangaxeshanye, i-automated warehouse ye-three-dimensional nayo inemisebenzi ukonga umhlaba, ukunciphisa ukunyanzeliswa kwabasebenzi, ukuphucula ukusebenza kakuhle kwamashishini, ukunciphisa ilahleko yokugcina nokuthutha, nokunciphisa iindleko zokuhamba.

Ithala leencwadi le-stereoscopic elizenzekelayo elizenzekelayo njenge/rs ukuhamba komsebenzi

Inkqubo yokusebenza ye-automated ye-warehouse ene-auto-dimensional three-dimensional as/rs iphuhliswe kwaye yakhiwa nguHebei hegris hegerls yokugcina ibhetri entsha yokuvelisa i-Co., Ltd. eYancheng, kwiPhondo laseJiangsu imi ngolu hlobo lulandelayo:

1 inkqubo yokugcina impahla

Indawo yokugcina impahla ibonelelwe ngetheminali yokugcina impahla kwindawo nganye yokugcina kunye neqonga lokugcina imveliso egqityiweyo kwindlela nganye yokunqumla. Ukuze iimveliso ezigqityiweyo zigcinwe, abasebenzi bendawo yokugcina iimpahla baya kuchwetheza igama, iinkcukacha, imodeli kunye nobungakanani bezinto, emva koko inkqubo yokulawula iya kufumana idatha egciniweyo ngokusebenzisa ujongano lwekhompyutha yomntu. Ngokwemigaqo yokusasazwa okufanayo, okokuqala ezantsi, emva koko, inzima kwaye ilula ezantsi, igcinwe kufutshane kunye nokuhlelwa kwe-ABC, i-calculator yolawulo iya kwabela ngokuzenzekelayo indawo yokugcina kwaye ikhawulezise indlela yokugcina impahla. Ngokutsho kwe-prompt, abasebenzi banokuthumela izinto ezilayishwe kwi-pallet eqhelekileyo kwi-platform yokugcina yendlela ngelori encinci yebhetri yezixhobo ezixhasayo kunye nezibonelelo; Imonitha iyalela i-stacker ukuba igcine iipaliti kwindawo echongiweyo.

Qaphela: kukho iindidi ezimbini zesitokhwe ekuqhutyweni kwedatha ye-inventri: okokuqala, abasebenzi kufuneka bafake igama (okanye ikhowudi), imodeli, inkcazo, ubuninzi, isitokhwe esikhoyo, iyunithi yokuvelisa kunye nolunye ulwazi kwi-stock kwi-tray kwi-stock. kumxhasi ngokusebenzisa ujongano lwekhompyuter yomntu emva kokugcinwa kwempahla; Okwesibini kukugcina impahla ngeepalethi.

2 inkqubo yonikezelo

Isiphelo esisezantsi yindawo yokuhanjiswa kwemveliso egqityiweyo. Igumbi lokulawula eliphakathi kunye netheminali ngokulandelelanayo ixhotyiswe ngeetheminali zokuhambisa. Izikrini zokubonisa i-LED zibekwe kwindlela nganye yokuhlangana ukuze kuqhutywe inani lokuphuma kweempahla eziza kuhanjiswa kwiqonga lendibano. Ukuze iimveliso ezigqityiweyo zihanjiswe kwindawo yokugcina impahla, emva kohlobo lwabasebenzi kwigama lemveliso, ukucaciswa, imodeli kunye nobuninzi, inkqubo yokulawula iya kufumanisa iipallets ezihlangabezana neemeko zokuhanjiswa kwaye zibe nobungakanani obufanayo okanye obuncinci ngokwemigaqo. okokuqala ukuphuma, ukuhanjiswa okukufutshane kunye nokuhanjiswa okuphambili, ukuguqula idatha yeakhawunti ehambelanayo, kwaye ngokuzenzekelayo uthumele zonke iintlobo zeepalethi zemveliso egqityiweyo kwidesika yonikezelo kumnyango wendlela nganye, eya kuthathwa yilori yebhetri kwaye isiwe kwindawo ekuyiwa kuyo. . Ngexesha elifanayo, inkqubo yokukhupha ivelisa uxwebhu lomcimbi kumxhasi emva kokugqiba umsebenzi womcimbi.

3. Ukucutshungulwa kokuhamba kwediski engenanto ibuyiselwe kwindawo yokugcina impahla

Emva kokuba ezinye iipalethi ezingenanto ukusuka kumgangatho osezantsi zipakishwe ngesandla, abasebenzi bachwetheza umyalelo wokubuya kwepalethi engenanto, kwaye ke abasebenzi baya kubathumela kwiNdlela ethile yokuwela kumgangatho osezantsi kunye nelori yebhetri ngokuhambelana nokukhawuleza. I-stacker iya kuzibuyisela ngokuzenzekelayo iipalethi ezingenanto kumnyango wokuqala we-warehouse ene-dimensional-dimensional, kwaye emva koko iworkshop nganye iya kukhupha iipalethi ezingenanto ukwenza inguqu ethile.

Ithala leencwadi le-stereoscopic elizenzekelayo elizenzekelayo njenge/rs lixhotyiswe ikakhulu ngezixhobo kunye nezibonelelo

itreyi e-1

Zonke iimpahla zamkela iipalethi ezidityanisiweyo nezisemgangathweni ukuphucula ukutshintshiselana kunye nokunciphisa ukulinda. I-pallet inokuhlangabezana nokulayishwa kunye nokulayishwa kwe-stacker, i-forklift kunye nezinye izixhobo, kwaye inokuhlangabezana nokusebenza kwi-conveyor.

2 ishelufu ephezulu

Amashalofu aphakamileyo athatha iishelufu ezikhethekileyo ezidibeneyo kunye nesakhiwo se-beam. Isakhiwo seshelufu sihle kwaye sinesisa, ukugcinwa kwezinto kunye nokusebenza, kwaye kulula ukuyifaka kunye nokwakha. Yeyolwakhiwo loyilo oluphuculweyo.

3 isitaki sendlela

Ngokweempawu zendawo yokugcina ibhetri entsha yokuvelisa i-Co., Ltd. eYancheng, kwiPhondo laseJiangsu, i-stacker ithatha isakhiwo senkxaso ephantsi, i-drive ephantsi kunye neekholamu ezimbini zecala. I-stacker isebenza kwiindlela ezintathu zokulungelelaniswa kwe-X, y kunye no-Z kwindlela ye-shelf ephezulu, igcina iimveliso ezibekwe kwindawo yokugcina kwindawo yokungena kwindlela yokungena kwigridi yempahla echongiweyo, okanye ukuthutha iimpahla kwigridi yempahla. ngaphandle kwiqonga lokugcina ekungeneni kwendlela. Uyilo kunye nokuveliswa kokuhamba kwe-stacking esetyenziswa yi-hegerls kuqhutyelwa ngokungqongqo ngokuhambelana nemigangatho yelizwe, kwaye amandla okwakhiwa kunye nokuqina kubalwa ngokuchanekileyo ukuze kuqinisekiswe ukusebenza kakuhle, ukuguquguquka nokukhuselekileyo kwendlela. I-stacker exhotyiswe yi-hegerls inendlela ekhuselekileyo yokusebenza ukukhusela ukwenzeka kweziganeko ngengozi. Isantya sokusebenza yi-4-80mm / min (i-variable frequency regulation), isantya sokuphakamisa i-3 / 16mm / min (iimoto ezimbini zesantya), isantya sefoloko yi-2-15mm / min (i-variable frequency regulation), isikhokelo sonxibelelwano. i-infrared, kwaye imo ye-elektroniki yimowudi yoqhagamshelwano yoqhagamshelwano.

4 ulawulo lwekhompyutha, ukubeka iliso kunye nenkqubo yokuthumela

Ulawulo lwekhompyuter, ukubekwa esweni kunye nokuhanjiswa kwenkqubo inokwaba ngokufanelekileyo kwaye ingene kuyo yonke imisebenzi yokugcina indawo yogcino lwe-automated-dimensional warehouse, kwaye yenze uhlalutyo lweenkcukacha-manani lwedatha yayo, ukuze kuqondwe ulawulo olukhethekileyo lolungiselelo, ukunciphisa umsebenzi woluhlu kunye inkunzi, kwaye kukhawuleziswe ingeniso eyinkunzi. Kumsebenzi wokufikelela kwimihla ngemihla, ngokukodwa kwi-off-site yokukhetha umsebenzi, akunakuphepheka ukuba kuya kubakho iimpazamo zokufikelela kwinqaku, ngoko ke i-inventory kufuneka iqhutywe rhoqo. Ukusetyenzwa kwe-inventri kuqinisekisa ukuchaneka kwedatha yezinto ze-inventri nge-inventri yangempela yepere nganye yezinto, kunye nokulungiswa kwangethuba ii-akhawunti ze-inventri ukufezekisa ukuhlanganiswa kwee-akhawunti kunye nezixhobo. I-stacker ayiyi kwenza ezinye iintlobo zemisebenzi ngexesha le-inventory. Ngethuba lokusebenza, i-stacker iya kukhupha i-inventory epheleleyo kwi-stacker kwindlela ethile yendlela, kwaye i-stacker iya kuthutha iimpahla kule ndlela ukuya ngaphandle kwendlela enye ngokulandelanayo. Iimpahla aziyi kulayishwa kwi-stacker. Emva kokufumana umyalelo wokubuyela kwindawo yokugcina impahla, i-stacker iya kubuyisela le tray yempahla kwindawo yayo yokuqala kwaye ikhuphe itreyi elandelayo yempahla, kwaye ityhale ngale ndlela de zibalwe zonke izinto zetreyi kule ndlela, Okanye faka. imeko eqhelekileyo yokusebenza emva kokufumana umyalelo wokunqunyanyiswa kwe-inventri kwinkqubo yokulawula. Ukuba umzila ufumana umyalelo wokuhlala okwethutyana phambi kokuba uluhlu lugqitywe, qhubeka ugqibezela umsebenzi woluhlu emva kokufumana umyalelo omtsha.

Isiphumo seprojekthi yesicelo:

1) Ngokwesiseko semimandla ephantsi, ulawulo olumanyeneyo lokuthunyelwa kwemathiriyeli kushishino lwamandla amatsha luphunyeziwe;

2) Idibanisa ngokufanelekileyo izixhobo zokugcina kunye nokuphucula inqanaba lolawulo lokugcinwa kweshishini;

3) I-Railed multi lane stacker +i-agv yokuphatha ngokuzenzekelayo, ukuqonda ukugcinwa okungekho mntu;

I-4) Ukudibanisa ukuguquguquka kunye nokuguquguquka, kuye kwakha indawo yokugcina impahla ehlangabezana neemfuno zeshishini elitsha lamandla.

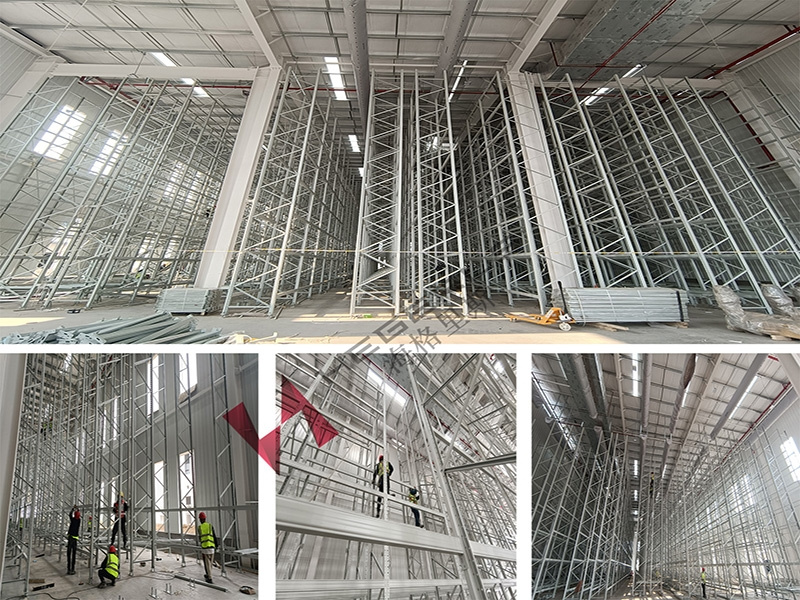

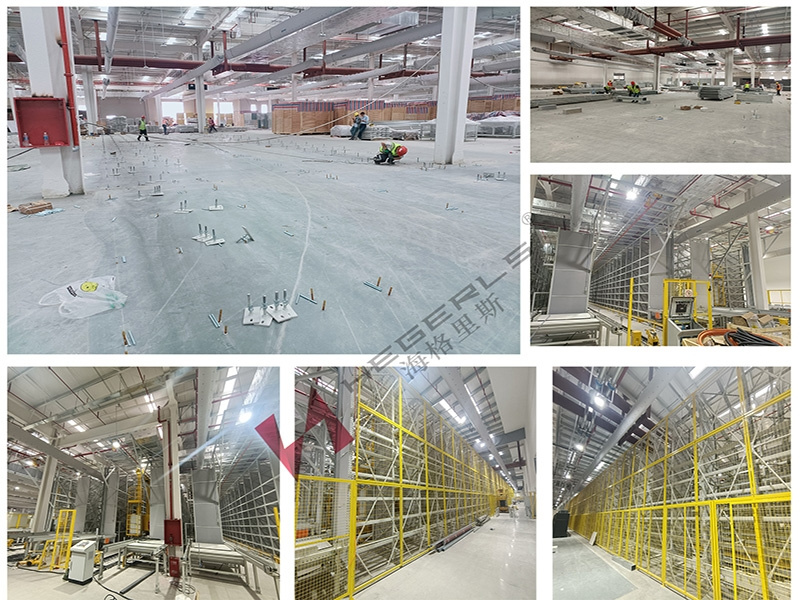

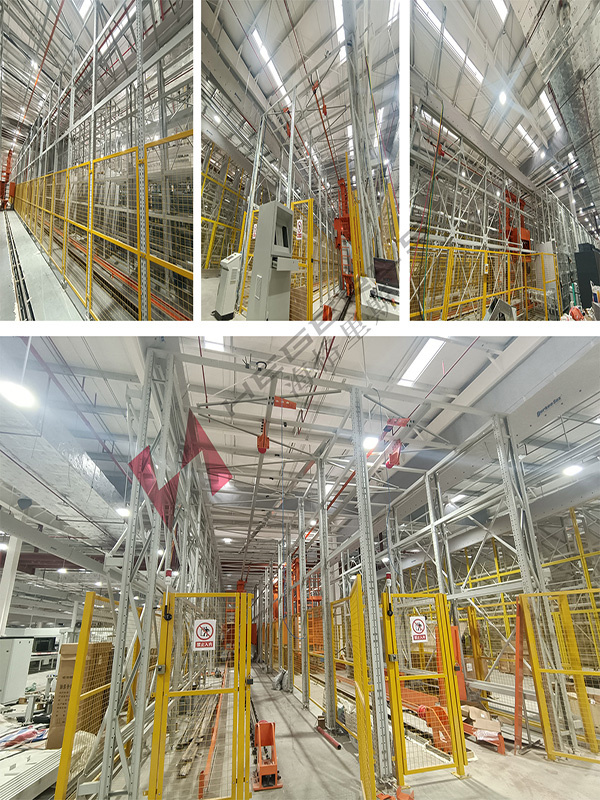

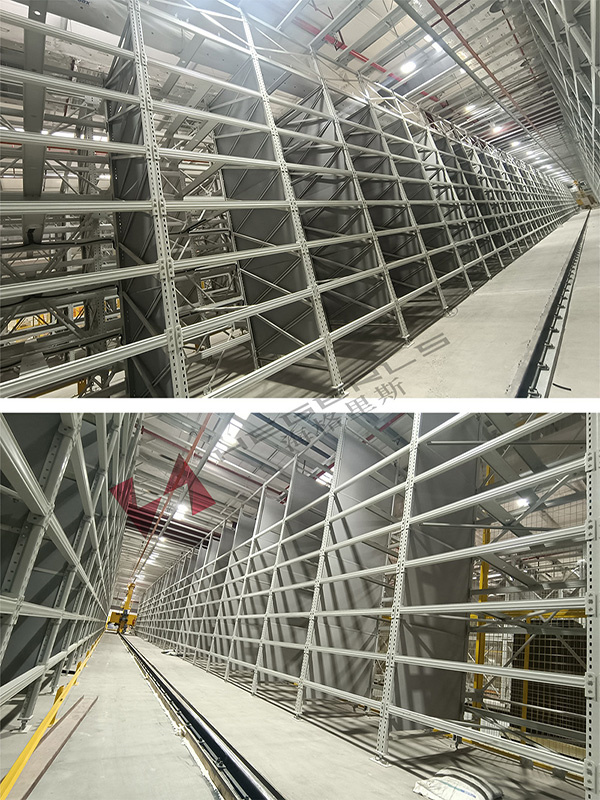

Ukufotwa kwendawo yeefoto zokwakha iprojekthi:

Ixesha lokuposa: Jun-24-2022