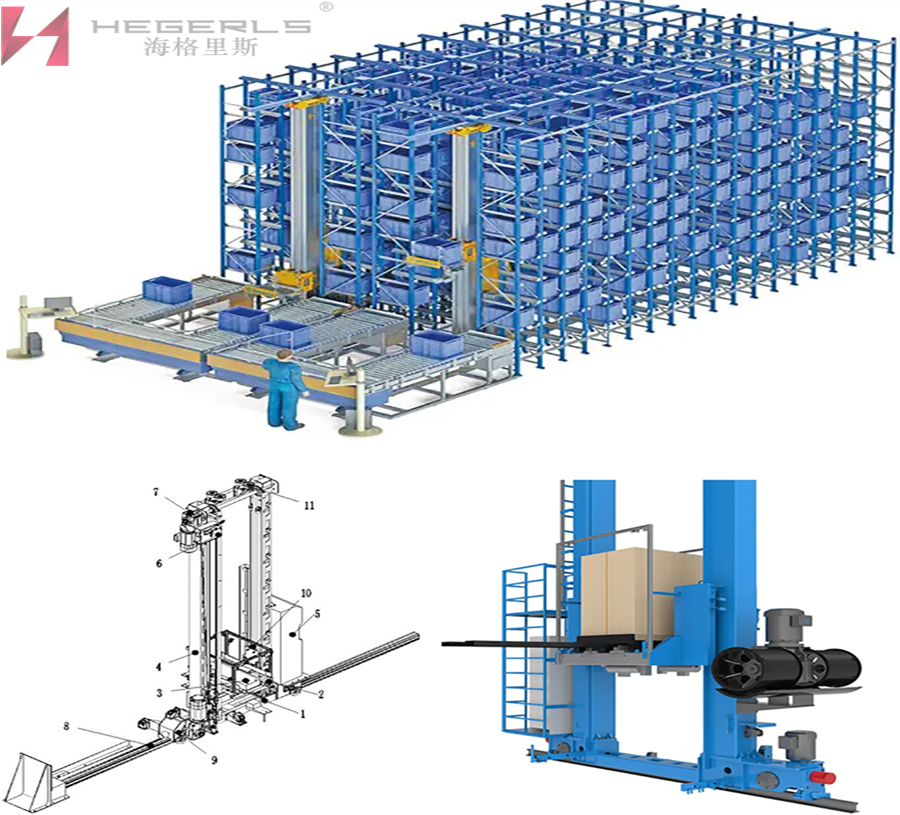

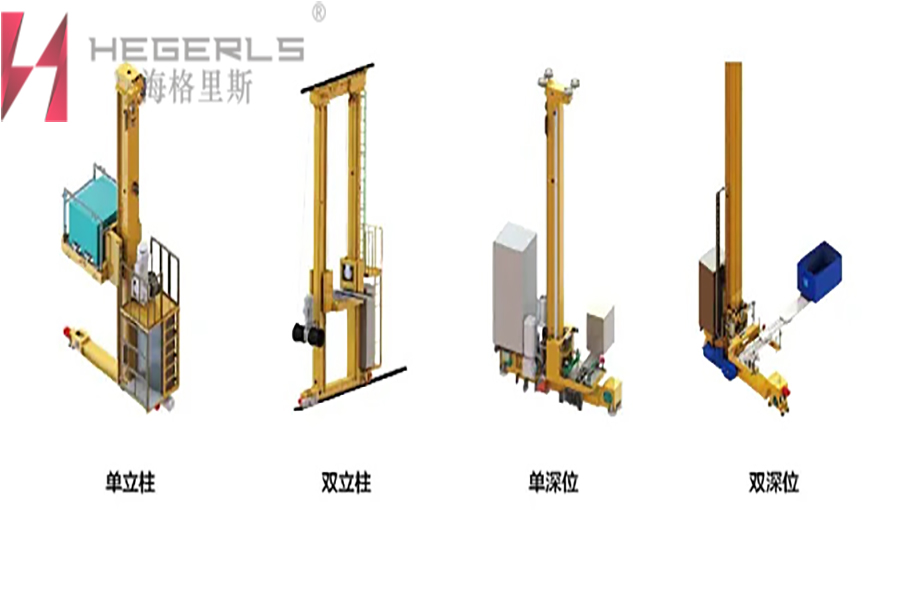

Njenge / RS warehouse yinxalenye ebalulekileyo yenkqubo yolungiselelo lwale mihla kunye nenkqubo yokugcina ephezulu yokugcina imigangatho emininzi kunye nokufumana, kubandakanywa inkqubo yokulawula indawo yokugcina impahla, iishelufu, iirobhothi, izitaki kunye neemoto zokuthutha. Ngaphantsi kolawulo lwenkqubo yekhompyuter ye-WMS, indawo yokugcina impahla inokuqonda ukugcinwa kwempahla ngokuzenzekelayo kwaye iqonde uthungelwano kunye nenkqubo yolawulo, eyeyamanyathelo olawulo lwangoku. I-stacker yeyona nto ibalulekileyo yokuphakamisa kunye nezixhobo zokuthutha kwi-warehouse ye-dimensional-dimensional kunye nesimboli esimele iimpawu ze-warehouse ezintathu-dimensional. Injongo yayo ephambili kukusebenza kumjelo we-warehouse ye-three-dimensional, ukugcina iimpahla kwindlela yokuwela kwigridi yempahla, okanye ukukhupha iimpahla kwigridi yeempahla kwaye uzithuthe ukuya kwindlela yokuwela.

Ukubunjwa kwesakhiwo se-stacker kubandakanya: umzila ophantsi, umzila wesikhokelo esiphezulu, iqonga lomthwalo, ipaneli yokusebenza kunye nemoto yokuphakamisa, kunye ne-stacker idityaniswe nenkqubo yolawulo ephezulu kunye nenkqubo yokulawula ukuqaphela ukuzenzekelayo kwempahla ngaphakathi nangaphandle kwendawo yokugcina impahla. Imowudi yonxibelelwano ye-infrared yamkelwa kwishelufu ye-stacker kunye ne-dimensional-dimensional. Akukho mfuneko yokucwangcisa iingcingo ezininzi kakhulu phakathi kweeworkshops, ezinamandla okumelana nokuphazamiseka. I-microcomputer ye-chip enye yeyolawulo lweziko lokulinganisa kunye neziko lokulawula, elinokuthi likhuphe imiyalelo yokuphendula ngexesha elifanelekileyo kwikhompyutheni yokulawula ephezulu kwaye iseke unxibelelwano kunye nekhompyutheni ephezulu ngexesha elifutshane.

Ngokuqinisekileyo, kumxholo wophuhliso olukhawulezayo lwentlalo noqoqosho, amashishini aya kuxhalaba ngakumbi ukuba phantsi kweemfuno zokusebenza okuphezulu, indawo yokugcina impahla yemveli ayinakukwazi ukuhlangabezana neemfuno, kodwa ukusetyenziswa kwe-stacker kwi-othomathikhi ye-warehouse enemigangatho emithathu idlala indima ephambili. Kule nkalo, umenzi weshelufu yokugcina i-Hercules Hergels uya kugxininisa kwiingxaki ezenzeke ekusebenziseni i-stacker, kwaye ubeke phambili izisombululo kwezi ngxaki.

Ngokuqinisekileyo, kumxholo wophuhliso olukhawulezayo lwentlalo noqoqosho, amashishini aya kuxhalaba ngakumbi ukuba phantsi kweemfuno zokusebenza okuphezulu, indawo yokugcina impahla yemveli ayinakukwazi ukuhlangabezana neemfuno, kodwa ukusetyenziswa kwe-stacker kwi-othomathikhi ye-warehouse enemigangatho emithathu idlala indima ephambili. Kule nkalo, umenzi weshelufu yokugcina i-Hercules Hergels uya kugxininisa kwiingxaki ezenzeke ekusebenziseni i-stacker, kwaye ubeke phambili izisombululo kwezi ngxaki.

Iimpazamo eziqhelekileyo kunye neendlela zokugcinwa kwe-stacker

Impazamo kunye nokungaqhelekanga kwesiguquli esithe tye

Xa isiguquli sefrikhwensi esithe tye sihluleka, ubukhulu becala kungenxa yokucotha okanye ukumisa isitaki esibangelwa (umthwalo ogqithisileyo, ukwehla ngokukhawuleza, njl. njl.).

Isisombululo sokugcinwa kukuba: i-stacker inokuguqulwa ibuyele kwindawo yokuqala, kwi-no-load kunye nesimo esichanekileyo sokumisa, kwaye emva koko usethe kwakhona.

Impazamo yokumisa ethe tye engaqhelekanga

Yintoni ukungazinzi okuthe tye? Ngamanye amazwi, iyasilela ukubaleka ukuya kwindawo yokumisa phakathi kwexesha okanye amaxesha athile.

Isisombululo solondolozo kukuba: sinokuqhubeka nokusebenza emva kokuba sisetwe kwakhona ngamaxesha athile; Nangona kunjalo, kwimeko eqhubekayo, kuyimfuneko ukujonga i-brake yokubamba okanye umkhondo wemoto ethe tye.

Impazamo engaqhelekanga yekhowudi ethe tye

Impazamo engaqhelekanga ye-encoder ethe tye ithetha ukuba ufundo lwe-encoder oluxwesileyo aluchanekanga.

Isisombululo sokugcinwa kukuba: ukuba ikhowudi yenqanaba ayiqhelekanga ngamaxesha athile, inokusetha kwakhona kwaye iqhubeke nokusebenza; Kwimeko yokwenzeka rhoqo, kuyimfuneko ukujonga ukuba i-encoder ikhululekile, kwaye emva koko ufundise ukufundisa kwakhona emva kokuhlolwa.

Ukungaphumeleli kwenqanaba lokufundisa kunye nempazamo engaqhelekanga

Ukufundisa okuthe tyaba kuyasilela, oko kukuthi, inani leekholam xa lifika ekupheleni ngexesha lokufundisa alingqinelani nekholam enkulu enikiweyo.

Isisombululo solondolozo kukuphinda ukufundisa okanye kutshekishwe ukuba inani elinikiweyo leekholamu lichanekile kusini na.

Impazamo kunye nokungaqhelekanga kwesiboni sedilesi yangaphambili ethe tye

Isisombululo sokugcinwa kukuba: xa kukho ukungaphumeleli kwe-recognition yedilesi yangaphambili ethe tyaba, unokujonga umgca, i-chip yokuqaphela idilesi, indawo yokutshintsha, njl.

Impazamo kunye nokungaqhelekanga kwesiboni sedilesi yangasemva ethe tye

Isisombululo sogcino sithi: xa impazamo yesiboni sedilesi engasemva ethe tyaba isenzeka, iyafana nempazamo yesazisi sedilesi yangasemva ethe tyaba. Kwakhona kuyimfuneko ukujonga isiphaluka, i-chip yokuqaphela idilesi, indawo yokutshintsha, njl.

Impazamo yokutshintsha umda wesantya sangasemva ayiqhelekanga

Isisombululo sokugcinwa kukuba: xa umyinge wesantya ongasemva uhluleka, sinokujonga isiphaluka, sisuse ibhodi yokukhanya okanye sitshintshe ukutshintsha. Ngexesha elifanayo, kufuneka sijonge kwakhona i-encoder ye-stacker.

Impazamo yokutshintsha umda wesantya sangaphambili ayiqhelekanga

Isisombululo solondolozo kukuba: ukusilela kokutshintsha kwesantya sangaphambili kuyafana nokusilela kokutshintsha kwesantya esingasemva, oko kukuthi, kukwayimfuneko ukujonga isekethe, ukususa ipleyiti yokukhanya okanye ukubuyisela iswitshi, kwaye ujonge. ikhowudi yesitaki.

Isiphene sokutshintsha kwesiphelo esingaqhelekanga | isiphene sokutshintsha kwesiphelo esingaqhelekanga

Isisombululo sokugcinwa simi ngolu hlobo lulandelayo: enyanisweni, xa umjikelo ongasemva uhluleka kwaye umjikelo wangaphambili ungaphumeleli, isisombululo sokugcinwa siyafana nesokungaphumeleli kokutshintsha kwesantya sangasemva kunye nokungaphumeleli kokutshintsha kwesantya sangaphambili. Kwakhona kuyimfuneko ukujonga isiphaluka, ukususa ipleyiti yokukhanya okanye utshintshe utshintsho, kwaye ukhangele kwakhona i-encoder ye-stacker.

Isiphene esingaqhelekanga sokusebenza okuthe tye

Yintoni i-horizontal operation reverse fault? Oko kukuthi, isalathiso sexabiso le-pulse ye-horizontal pulse encoder ichasene nesalathiso somqondiso wentshukumo onikiweyo.

Isisombululo sokugcinwa kukuba: kufuneka sihlolisise ukuba imigca ye-A kunye ne-B ye-encoder ye-pulse ixhunyiwe ngokuchanekileyo, okanye ngaba ukulandelelana kwesigaba sokunikezelwa kwamandla kuchanekile.

Impazamo ayiqhelekanga emva kokuba i-stacker ihlehlile ukuya kuloliwe wokugqibela

Xa i-stacker ibuyela kumqolo wokugqibela, lo mcimbi kungenxa yokuba ubuncinane idilesi enye ethe tye ye-stacker ishiya isiphelo esingasemva seqhekeza ledilesi kwindawo yokugqibela yekholamu.

Isisombululo sokugcina: into ekufuneka siyenze kukujonga ibhuleki yebhendi ethe tyaba, isixhobo sokuqaphela idilesi, iqhekeza lokuqaphela idilesi, kunye nepleyiti yokususa ukukhanya kwesixhobo ngasinye sokuqaphela idilesi.

Impazamo phambi koyena loliwe mkhulu phambi kwesitaki ayiqhelekanga

Yintoni ephambi kwestacker naphambi koyena loliwe mkhulu? Ngapha koko, kuthetha ukuba ubuncinci idilesi enye ethe tyaba yesitaki iphumile ngasemva kwetshiphu yokuqaphela idilesi ngaphambili.

Isisombululo sokugcinwa kukuba: into ekufuneka yenziwe kukujonga ibhuleki yebhendi ethe tyaba, isixhobo sokuqaphela idilesi, isiqwenga sokuqaphela idilesi, kunye nepleyiti yokususa ukukhanya kwesixhobo ngasinye sokuqaphela idilesi.

Impazamo yokutshintsha umda wesantya ayiqhelekanga

Isisombululo sogcino sithi: enyanisweni, intsingiselo yokoqobo nayo iqondwa kakuhle. Isisombululo sokugcinwa kukujonga isiphaluka, ibhodi yokukhawulela isantya kunye nokutshintsha ukutshintsha.

Isantya sesitaki sisezantsi kakhulu kwaye asiqhelekanga

Impazamo yesantya esisezantsi se-stacker ayiqhelekanga, oko kukuthi, i-stacker ayikwazi ukuqhuba kwindawo ixesha elide emva kokungena kwi-chip yokuqaphela idilesi.

Isisombululo sogcino kukuba: xa loo mpazamo isenzeka ngokungaqhelekanga, into ekufuneka ijongwe ngumatshini, umzila okanye ukonyusa kancinane isantya sokupaka.

Impazamo kunye nokungaqhelekanga kwidilesi ethe tye

Ngapha koko, kuqondwa kakuhle ukuba xa nayiphi na idilesi ethe tye iyasilela okanye isebenza ngokuzenzekelayo, i-stacker iye yabaleka ukuya kuloliwe oya kuyo, kodwa isiqwenga sedilesi asikhange sifumaneke ngaphakathi koluhlu oluchaziweyo lwe-pulse.

Isisombululo sokulondoloza kukuba: xa sinokusetwa kwakhona ngamaxesha athile, sinokuqhubeka nokusebenza; Nangona kunjalo, kwimeko yokwenzeka okuqhubekayo, kuyimfuneko ukujonga ukuba isiboni sedilesi esithe tye siqhelekile.

Ukungaphumeleli kwenqanaba lokufundisa kunye nempazamo engaqhelekanga

Isisombululo solondolozo sesi: oko kukuthi, inani lilonke leekholamu ezichazwe ngokuthe tye alihambelani nenani leekholamu ezibalelwe ukufundisa. Xa le mpazamo ingaqhelekanga, kuyimfuneko ukujonga inani elipheleleyo leekholomu ezichaziweyo. Ubuninzi bekholamu ye-stacker yendlela yintsika ezili-100 kunye netshiphu yokuqaphela idilesi ethe tye, kunye nokuba isixhobo sokuqaphela idilesi sinokuyiva.

Impazamo yempazamo kumhlathi wendawo yokufikela

Isisombululo sokugcina: oko kukuthi, indawo yokusebenza ye-stacker ayihambelani naleyo ikhutshiweyo. Ngeli xesha, into ekufuneka yenziwe kukukhangela idilesi yendawo yokusabalalisa, ukucacisa ukusebenza kunye nokusabalalisa kwakhona umsebenzi.

Impazamo yesiguquli sefrikhwensi ethe nkqo kunye nokungaqhelekanga

Isisombululo sogcino sithi: ngoko yintoni impazamo engaqhelekanga yesiguquli esithe nkqo samaza? Ngapha koko, ukukhuselwa kwesiguquli esithe nkqo sibangelwa kumthwalo ogqithisileyo okanye ukwehla ngokukhawuleza okukhulu. Isisombululo esinikwe nguHercules Hergels umenzi weshelufu yokugcina i-stacker ukuguqula i-stacker kwindawo yokuqala, kwindawo yokungalayishwa kunye nechanekileyo yokumisa, kwaye uphinde usethe kwakhona.

Impazamo yokumisa ngokuthe nkqo engaqhelekanga

Isisombululo sokugcina: into ebizwa ngokuba yi-vertical stop inaccuracy ithetha ukuba i-stacker idlula inani elichaziweyo lamaxesha ngexesha eliphindaphindiweyo lokunyuka nokuwa kwesantya. Umvelisi weshelufu yokugcina iHercules naye ufumene impendulo evela kubathengi abasebenzisanayo kule ngxaki engaqhelekanga. Ngokusekelwe kwiminyaka emininzi yamava, umenzi weshelufu yokugcina iHercules unezisombululo kule ngxaki. Iyafana nezinye zezi ngxaki zingasentla. Ngokufanayo, xa isenzeka ngamaxesha athile, inokusetwa kwakhona ngaphambi kokuba iqhubeke; Nangona kunjalo, ukuba le mpazamo yenzeka ngokuqhubekayo, kuya kufuneka ujonge i-motor ethe nkqo ebambe ibhuleki okanye umkhondo.

Impazamo engaqhelekanga yokufakwa kweekhowudi nkqo

Isisombululo sokugcina: esi siphoso asiqhelekanga, oko kukuthi, idatha efundwa yi-encoder ethe nkqo ayilunganga. Xa oku kungaqhelekanga kusenzeka, okanye ngamaxesha athile kusenzeka, kunokusetwa kwakhona kwaye emva koko kuqhubeke ukusebenza; Xa le meko iqhubeka ngokuqhubekayo, kuyimfuneko ukujonga ukuba i-encoder ikhululekile, kwaye emva koko ufundise kwakhona emva kokuhlolwa.

Ukusilela ekufundiseni ngokuthe nkqo kunye nempazamo engaqhelekanga

Isisombululo solondolozo kukuba: ukufundisa ngokuthe nkqo kuyasilela, oko kukuthi, xa ukufundisa kufikelela ekupheleni, inani leeleya alihambelani nomgangatho onikiweyo; Kule nto, umenzi we-hegerls ishelufu yokugcina i-hagris icebisa ukuba inani elinikiweyo leeleya lifundiswe okanye lihlolwe kwakhona, kwaye ingaba i-chip yokuqaphela idilesi kunye ne-rectick idilesi ye-recicter yomaleko ngamnye inokuyibona.

Umphezulu othe nkqo (ephantsi | phezulu) impazamo yedilesi ayiqhelekanga

Isisombululo sokugcina: xa le mpazamo ingaqhelekanga, kuyimfuneko ukujonga isiphaluka, ukususa ibhodi yokukhanya okanye utshintshe utshintsho, kwaye ukhangele umhleli we-stacker.

Umda wesantya esiphezulu | Impazamo yokutshintsha isantya esisezantsi ayiqhelekanga

Isisombululo sokugcina: umda wesantya esiphezulu kunye nokutshintshwa kwesantya esisezantsi akuqhelekanga, okuqondwa kakuhle. Isisombululo kukukhangela ngokuthe ngqo isiphaluka, ukususa ipleyiti yokukhanya okanye utshintshe utshintsho. Ngokuqinisekileyo, i-encoder ye-stacker kufuneka ihlolwe ngexesha elifanayo.

Isiphene esingaqhelekanga sokusebenza ngokuthe nkqo

Isisombululo sokugcina: esi siphoso kukuba isalathiso sexabiso le-pulse ye-vertical pulse encoder ichasene nesalathiso somqondiso onikiweyo; Ngexesha lokugcinwa kwayo, abasebenzi baya kujonga ukuba ngaba imigca ye-A kunye ne-B ye-encoder ye-pulse ixhunyiwe ngokuchanekileyo, okanye ukuba ukulandelelana kwesigaba sokunikezelwa kwamandla kuchanekile.

Impazamo yokhuseleko lokukhulula intambo yerhuluneli yesantya ayiqhelekanga

Isisombululo sokugcinwa kukuba: xa kukho impazamo ekukhuselweni kwentambo evulekileyo yerhuluneli yesantya, qiniseka ukuba ukhangele ukuba intambo yentsimbi ye-speed governor ikhululekile. Ukuba kunjalo, abasebenzi kufuneka bajonge kwaye balungise.

Impazamo phantsi kwetshiphu yokuqaphela idilesi yowona maleko usezantsi kunye nowona maleko uphezulu wepalethi awuqhelekanga.

Isisombululo sokugcinwa simi ngolu hlobo lulandelayo: eqinisweni, isiphelo esisezantsi okanye esingaphezulu kwesicatshulwa sokuqaphela idilesi sibonakala kuzo zombini izixhobo zokuqaphela idilesi kwiqonga lempahla ezantsi okanye phezulu. Isisombululo kukukhangela ngokuthe ngqo i-brake yokubamba ngokuthe nkqo, isixhobo sokuqaphela idilesi kunye neqhekeza lokuqaphela idilesi.

Impazamo yesantya esithe nkqo

Isisombululo sogcino sithi: impazamo ethe nkqo ye-overspeed ayiqhelekanga, oko kukuthi, esona santya sifunyenweyo sidlula uluhlu oluchaziweyo lwesantya esinikiweyo. Umvelisi weshelufu yokugcina i-hegris hegerls uncoma ukujonga i-wiring ye-motor wiring kunye nokubamba i-brake.

Idilesi ethe nkqo kwimpazamo

Isisombululo sogcino simi ngolu hlobo lulandelayo: impazamo yesazisi sedilesi ethe nkqo ayiqhelekanga, oko kukuthi, xa nayiphi na idilesi ethe nkqo iyasilela okanye iqhuba ngokuzenzekelayo, ipallet iye yabaleka ukuya kwindawo ekuyiwa kuyo, kodwa isiqwenga sedilesi asifumanekanga ngaphakathi kwendawo echaziweyo. Uluhlu lwe-pulse yempazamo. Yintoni ekufuneka yenziwe lishishini kukukhangela ukuba iswitshi kunye nesekethi yonakele na okanye ukuba iswitshi kunye ne-chip yokwazisa idilesi ziyasebenzisana.

Impazamo yerotha etshixiwe ngefolokhwe ayiqhelekanga

Isisombululo solondolozo kukuba: amashishini amaninzi anokuthi adibane nale ngxaki yempazamo, oko kukuthi, ifolokhwe ayinwetshwanga (ihoxisiwe) kwindawo ngexesha elichaziweyo. Xa le ngxaki isenzeka, kufuneka sijonge ukuba ngaba kukho imiqobo kwindlela yolwandiso lwefolokhwe okanye indlela yefolokhwe ikhululekile; Xa ucinezela iqhosha lomsebenzi weGreen ukucima impazamo, uze ucinezele ifolokhwe yokwandisa kwaye usebenze ngokuphindaphindiweyo de ifolokhwe iyeke ngokuchanekileyo.

Impazamo yokukhangela ifolokhwe ephezulu ayiqhelekanga

Isisombululo sokugcina: oko kukuthi, xa ifolokhwe inesithuba esiphakathi, ubuncinane enye ifoloko ephezulu yokukhangela indawo yokukhangela indawo ayinayo uphawu, okanye ifolokhwe ephezulu ayifumani indawo ephakathi; Kwimeko yokungaphumeleli kokutshintsha kwefolokhwe ephezulu, kuyimfuneko ukujonga ukuba itshintshi kunye nesekethe yonakaliswe, okanye ukuba umtshintshi uhambelana nomlawuli wempembelelo. Ngexesha elifanayo, kuyimfuneko ukujonga ukuba ifoloko ibuyele kwindawo yayo yokuqala.

Impazamo yokutshintsha kwefolokhwe yokungathathi hlangothi ayiqhelekanga

Isisombululo sokugcinwa kukuba: xa ifolokhwe yokumisa i-middle stop switch ingaqhelekanga, kuyimfuneko ukujonga ukuba i-switch kunye nesiphaluka zonakalisiwe okanye ukuba umtshintshi kunye nomlawuli wempembelelo uyasebenzisana.

Uphononongo lwefolokhwe ekhohlo | isiphene sokutshintsha inkqubo yasekunene ayiqhelekanga

Isisombululo sokugcinwa kukuba: xa ukukhangela kwesobunxele okanye ekunene kwefoloko kungaphumeleli, kuthetha ukuba ukukhangela kwekhohlo okanye ekunene kwefoloko akunakukwazi ukubona i-pallet. Ngeli xesha, into ekufuneka siyenzile kukujonga ukuba umtshini kunye nesekethe zonakaliswe okanye zilungelelanise ngokuthe ngqo impazamo yokukhangela.

Ekhohlo | ukufunyaniswa kwe-skew ekunene tshintsha impazamo engaqhelekanga

Isisombululo solondolozo kukuba: xa i-ekhohlo | iswitshi yokukhangela i-skew ekunene ingaqhelekanga, khangela ukuba iswitshi kunye nesekethe yonakalisiwe kwaye itshintshi kunye nesibonisi siyasebenzisana.

Ukutshintshela ukukhangela umthwalo wepallet kunempazamo okanye ayiqhelekanga

Isisombululo sokugcinwa kukuba: xa ukutshintshwa kwempahla ye-cargo ye-platform yokulayisha inesiphoso esingaqhelekanga, kuyimfuneko ukujonga ukuba umtshini kunye nesiphaluka zonakaliswe kwaye ingaba umtshintshi kunye nomboniso uhambelana.

I-inching timeout impazamo engaqhelekanga

Isisombululo sokugcina simi ngolu hlobo lulandelayo: xa i-pallet ingaphakami kwindawo ephezulu xa ithatha iimpahla okanye ingaweli kwindawo ephantsi xa igcina iimpahla ngexesha elichaziweyo, abasebenzi kufuneka baqale bahlole ukuba ngaba idilesi yomqaphi wedilesi. yonakele okanye ukuba iswitshi kunye nesazisi sedilesi ziyahambelana.

Impazamo engaqhelekanga yentambo yokhuselo

Isisombululo sokugcina: xa intambo yentsimbi ikhululekile okanye iphukile, jonga ukuba kukho i-alamu yobuxoki kwaye uqhagamshelane nabasebenzi benkxaso yobugcisa.

Ukungaqheleki kokhuseleko lomthwalo ogqithisileyo | ukuphambuka komthwalo ongaphezulu komthwalo

Isisombululo sokugcina: xa iimpahla zigqithise okanye ziphezulu kakhulu, kuyimfuneko ukuhlenga iimpahla ngaphambi kokuba usebenze kwakhona.

Impazamo yomthwalo omde engaqhelekanga

Isisombululo sokugcinwa simi ngolu hlobo lulandelayo: i-fault phenomenon yempahla engaphezulu kwexesha elide kukuba xa i-stacker ikhupha iimpahla ekupheleni, iya kufumanisa ukuba kukho iimpahla kwi-conveyor. Xa le nto isenzeka, kuyimfuneko ukususa iimpahla ezihambelanayo phambi komthumeli kwaye ucinezele iqhosha lokuseta kwakhona ukusetha kwakhona.

Impazamo yokhuseleko lwefolokhwe ayiqhelekanga

Isisombululo sokugcina: Oku kungenxa yokuba ukuba iqhutywe ixesha elide okanye ilayishwe kakhulu, iya kukhokelela ekukhuselweni kwe-thermal relay yefoloko. Ukuba oku kuyenzeka, vula ikhabhinethi yolawulo kwaye ucinezele umnxeba obomvu we-"fr" relay thermal.

Impazamo yendlela yokufundisa ayiqhelekanga

Isisombululo sogcino sithi: xa imo yokufundisa ingaphumeleli, isisombululo sogcino kukucima umbane kwaye uqalise ngokutsha emva kokufundisa, uze ucinezele isisombululo sokuseta ngokutsha ukusombulula le ngxaki.

Kukho ingxaki yokusebenza engaqhelekanga ngexesha lokuqalisa

Isisombululo sokugcina: kukho umsebenzi ngexesha lokuqalisa, oko kukuthi, umsebenzi omnye ugcinwa emva kokuvalwa, ngoko ke ukusombulula le meko? Kunjalo, ungacofa iqhosha lomsebenzi ukuseta ngokutsha okanye ukucima umsebenzi wangoku.

Impazamo yephalethi ephezulu yokungena kwindawo engeyiyo ayiqhelekanga

Isisombululo sokugcina: into ebizwa ngokuba yi-pallet ephezulu ingena kwindawo engafanelekanga kukuba umsebenzi ubonisa indawo ephantsi kunye nempahla ye-pallet iphezulu kakhulu. Kule meko, kuyimfuneko ukukhupha kwakhona ukusebenza kwaye emva koko ulayishe iimpahla kwakhona.

I-skew yempahla engaqhelekanga / impazamo yobubanzi obungaphezulu

Isisombululo sokugcinwa kukuba: iimpahla zigobile okanye i-ultra wide, eneneni ibhekisela kwi-skew yempahla ye-pallet. Xa le nto isenzeka, kuyimfuneko ukuhlenga iimpahla ze-pallet kwaye ukhangele ukuba i-switch yokubona iphosakele.

Stacker blind impazamo engaqhelekanga

Isisombululo sokugcinwa kukuba: ikhowudi ebizwa ngokuba yi-stacker blind code ithetha ukuba iskena asiskeneli ikhowudi yebha. Ingcebiso enikwe nguHercules Hergels umenzi weshelufu yokugcina kukukhuhla iswitshi yokuskena kwaye ujonge ikhowudi yebha.

Unxibelelwano olungaqhelekanga nomthumeli

Isisombululo sokugcinwa kukuba: xa kukho ukungaphumeleli konxibelelwano kunye nomqhubi kunye nomatshini awukwazi ukuhamba, into yokuqala ukujonga ukuba ngaba umgca uxhunyiwe.

Akukho mpazamo yephalethi ngaphandle kumgca womsebenzi

Isisombululo sogcino sesi: amanye amashishini anokuthi ngenene adibane nesenzeko sokuba akukho phalethi injalo kumgca wokusebenza. Xa oku kusenzeka, banokukhupha ipalethi kuqala, baze babeke ipalethi emva kokukhupha utyando.

Iphalethi yangoku ingena kwindlela engalunganga, kwaye impazamo ayiqhelekanga

Isisombululo sokugcina: xa i-pallet yangoku ingena kwindlela engafanelekanga kwaye ihluleka, kufuneka iphinde ibeke i-pallet.

Akukho mpazamo okanye ukungaqhelekanga ekuchongeni

Isisombululo solondolozo kukujonga ubume bendawo yomthwalo ngokuthe ngqo xa kukho ukuchola okanye akukho singxobo.

Impazamo yogcino kabini

Isisombululo sokulungiswa kukuba: xa kukho i-warehousing ephindwe kabini, into ekufuneka yenziwe kukujonga imeko yendawo okanye ukubona ngokuthe ngqo ukutshintshela.

Ukusebenza ngokungekho mthethweni | umaleko wokusingwa wempazamo

Isisombululo sogcino sithi: xa ezi meko zimbini zisenzeka, into ekufuneka siyenzile kukuphinda sikhuphe umsebenzi.

Inombolo yetreyi engalunganga, impazamo engaqhelekanga

Isisombululo sogcino sithi: ngokuqhelekileyo, ukuba inombolo yepalethi eskeniweyo yahlukile kwinombolo yepalethi yokusebenza, okanye ukuba ipalethi ayiskenwanga, umsebenzi nawo ufuna ukuphinda ukhutshwe.

Ixesha lokuvala umsebenzi womthumeli | umiselo olungxamisekileyo lwempazamo yokuyeka

Isisombululo solondolozo kukuba: xa umhambisi eqhuba ixesha elongezelelekileyo okanye kukho ukumisa okungxamisekileyo, cofa nje iqhosha lokuseta kwakhona.

Ukubona impazamo yokutshintsha umoya

Isisombululo sokugcinwa kukuba: xa kukho impazamo yokufumanisa ukutshintshwa komoya, kuyimfuneko ukujonga ukuba umtshintshi kunye nesekethe ziqhelekileyo.

Iphalethi ngaphakathi / ngaphandle kwempazamo yongquzulwano

Isisombululo sogcino ngolu hlobo lulandelayo: xa ungquzulwano kunye nokungaphumeleli okungaqhelekanga kwe-pallet ngaphakathi nangaphandle kwendawo yokugcina impahla kwenzeka, into ekufuneka siyenze kukulungelelanisa ngaphakathi nangaphandle kwendawo yokugcina impahla.

Impazamo yobungakanani bePallet ayiqhelekanga

Isisombululo sokugcina: xa ubukhulu betrayi bungaqhelekanga, lungisa nje indawo ye-tray.

Umphakamo ophezulu wetreyi | ububanzi obungasekhohlo ngasekhohlo | ukungaqhelekanga kwempazamo yobubanzi obukhulu

Isisombululo solondolozo kukuba: xa i-pallet inobude obuphezulu, ububanzi obushiyekileyo kunye nobubanzi obuchanekileyo, kufuneka ikhowudi kwakhona ngokuthe ngqo kwimpahla.

Unxibelelwano olungaqhelekanga kunye ne-stacker

Isisombululo sokugcinwa kukuba: xa usebenzisa i-stacker, kuya kubakho ukungaphumeleli konxibelelwano kunye ne-stacker kwaye i-pallet ayiyi kuhamba. Ngeli xesha, yima kwaye ujonge ukuba umgca uqhagamshelwe.

Ixesha lokuposa: May-23-2022