Ishelufu yephalethi yeCrossbeam, ekwabizwa ngokuba yishelufu enzima, lolona hlobo luxhaphakileyo lweshelufu enokuchola kakuhle. Ngenxa yokuba ingxinano yokugcina i-rack yayo esisigxina iphantsi kwaye izinto ezigciniweyo zinzima, kufuneka zisetyenziswe kunye ne-pallet kunye ne-forklift, ngoko ke ikwabizwa ngokuba yi-pallet rack. Xa ukhetha iishelufu zephalethi ye-cross beam, ubukhulu, ubunzima kunye ne-stackinglayers ye-pallets kunye nempahla kufuneka ziqwalaselwe ukugqiba iintsika ezifanelekileyo kunye nokulinganisa ubungakanani. Ukongeza, ukuze kuphuculwe izinga lokusetyenziswa kwendawo, ububanzi betshaneli bungancitshiswa, zidityaniswe nefom ye-stacker ekhethekileyo yokwenza indawo yokugcina ime nkqo, oko kukuthi, ibe yindlela emxinwa yohlobo lwe-rack yezinto. Ke xa usebenzisa ishelufu yephalethi yohlobo lwendawo yokugcina impahla enzima, kufuneka uqale uyiqonde. Ngoku makhe sikuse kwindawo yokugcina i-hegerls ye-haggis ukuze uqonde ishelufu yephalethi yohlobo lwe-beam yokugcina indawo enzima kunye nendlela ethe yaba yindawo yokugcina i-automated ye-automated three-dimensional kumashishini amaninzi!

IHagerls ngumthengisi weshelufu obanzi odibanisa i-R & D, imveliso, intengiso kunye nenkonzo. Ukusukela ekusekweni kwayo, inkampani ibambelele kumgaqo-siseko wokuthembeka, umthengi kuqala kunye nomgangatho, kwaye iye yanconywa kakhulu ngabathengi abaninzi kwishishini. Ngokukodwa, inkampani inamahlakani exesha elide kwinkalo yolungiselelo kunye nokugcinwa kwezinto, ishishini lemichiza yezonyango, ukwenziwa kweemoto, iifektri zomkhosi, njl. njl. ukuze kuqaliswe iimveliso ezintsha kumaxesha ngamaxesha ukuhlangabezana neemfuno zabathengi abahlukeneyo, kwaye kunyuswe imigangatho yoyilo kunye neengqikelelo zeeshelufu ukuya kwinqanaba elitsha, elikwalisikhokelo sophuhliso lobuchwepheshe bethu.

I-Hegerls nayo inezixhobo ezigqibeleleyo zokuvelisa ishelufu. Inkampani izalisekisa ngokungqongqo imigangatho yenkqubo yomgangatho we-ISO, kwaye iyila kwaye yenza iishelufa ezinomthamo oqinileyo wokuthwala, ukuxhathisa ukubola, ulwakhiwo olufanelekileyo, ukuchithwa okufanelekileyo kunye nokuhlanganisana, kunye nokudityaniswa okungacwangciswanga ngokweemfuno ezahlukeneyo zabathengi ngesiseko sethiyori yoomatshini kunye netekhnoloji yesakhiwo sentsimbi. I-Tailor yenzelwe abathengi bayo ukuhambisa iikhonsepthi zolungiselelo lwangoku. Ngolawulo olugqibeleleyo, izixhobo zale mihla kunye nophuhliso olunesantya esiphezulu, i-hegerls ibheka phambili kwishishini langoku lolungiselelo kunye nokugcinwa kwempahla.

Ngelo xesha, i-factory ineminyaka emininzi yamava kwimveliso, ukufakwa kunye nokugunyaziswa kweendawo zokugcina ezinkulu. Ngokweemfuno zomthengi, isicwangciso somgangatho wendawo yokugcina impahla sinokulinganiswa kwindawo, kunye neskimu sokugcina indawo efanelekileyo sinokunikezelwa ngokweemfuno zomthengi. Umzi-mveliso uxhasa iimfuno zomntu ngamnye. Umzekelo, umbala, ubungakanani, iimfuno ezithweleyo zomaleko ngamnye weshelufu, njl. njl

Iindidi ezininzi ezahlukeneyo zeeshelufu zokugcina kunye nezixhobo zokugcina eziveliswe yi-Hegels zihluke kwabanye abavelisi. Ngoku makhe sijonge umahluko phakathi kwe-Hegels beam enzima kwiishelufu zepallet?

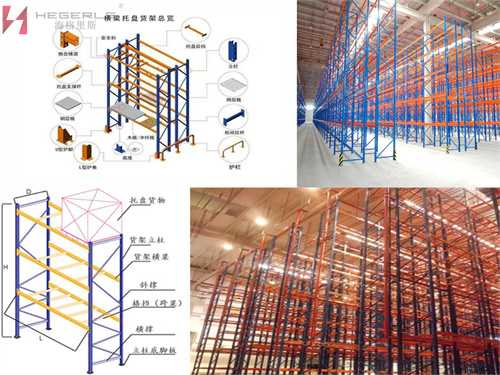

I-Hagerls - i-pallet ye-cross beam isakhiwo seshelufu

Isiqwenga sekholomu: yenziwe ngeekholamu ezimbini, ibrace ezinqamlezileyo kunye neebrace zediagonal ezidityaniswe ziibholiti zokuzitshixa zenayiloni. Isakhiwo esidibeneyo sithintela ngokufanelekileyo ukungazinzi kweshelufu okubangelwa ukukhulula iibholithi. Iikholomu zibethelwa ngemigca emibini yemingxuma ye-rhombic, kwaye i-pitch pitch yi-75mm okanye i-50mm. Ngoko ke, umqadi oxhonywe kwikholamu unokulungiswa phezulu naphantsi ngokukhululekileyo nge-75mm okanye i-50mm njengendawo enye. Icandelo lomnqamlezo wekholomu liqulunqwe ubuso be-11 ~ 13, kunye nomgama omkhulu we-inertia, amandla okuthwala anamandla kunye nokuchasana kwempembelelo enamandla. Ikholamu yeshelufu yomnqamlezo ithatha itekhnoloji yokubethela ngokuzenzekelayo kuqala kwaye emva koko igobe ibanda, ethintela ukusilela okunokwenzeka kokuqhekeka kwekholamu ngenxa yoxinzelelo loxinzelelo lwekholamu. Ukuthintela ukungqubana kwee-forklifts, iikholomu zixhotyiswe ngokubanzi ukukhusela.

I-Crossbeam: idityaniswe ngezibophelelo zekholamu ezimbini kunye neentonga ezinqamlezileyo. I-crossbeam idityaniswe yimiqadi emibini ekhethekileyo yokubamba i-welding ukuze iphindwe kabini ubukhulu beendawo eziphezulu nezisezantsi ze-crossbeam. Ngokwe-theory yoyilo lwesakhiwo sensimbi, esi sakhiwo sisebenzisa ngokupheleleyo umthamo womthwalo wezinto eziphathekayo, kunye neempawu zobunzima bokukhanya, umthamo oqinileyo womthwalo kunye neendleko eziphantsi. Xa i-boam idibaniswe nekholomu, ixhotyiswe ngepini yokhuseleko eyenzelwe ngokukhethekileyo kunye neelugs. I-pin yokhuseleko ene-lugs ayikwazi ukutsalwa ngokulula, enokuqinisekisa ukuba i-boam ayiyi kuwa emva kokuba ichaphazeleke ngamandla angaphandle.

I-Heigris hegerls - iinkcukacha zesakhiwo sendawo yokugcina impahla enemigangatho emithathu eneshelufu yephalethi enqamlezileyo

I-laminate yamandla aphezulu: ukubonakala kwenziwa ngokukhetha, i-phosphating, ukutshiza umgca wendibano ngokuzenzekelayo kunye nokubhaka kwepeyinti yokushisa okuphezulu, kunye nefuthe elibi kakhulu;

I-Crossbeam: ithatha i-hook hole design, efakwe ngokufanelekileyo kunye nekiti kwi-crossbeam, ekulungele ukuchithwa kunye nokudibanisa. Xa kuthelekiswa neshelufu yensimbi ye-angle, igcina i-1/2 yexesha lokufakela kwaye iphucula kakhulu ukusebenza kakuhle;

Itekhnoloji ye-welding ephezulu: i-brace ene-dimensional ezintathu-dimensional ethe tyaba kunye ne-diagonal brace i-welded ukunyusa umthamo wokuthwala i-dimensional-dimensional;

Umgangatho odibeneyo: uphucula ukungqubuzana phakathi kweshelufu kunye nomhlaba kunye nokuphucula ukuzinza kweshelufu;

I-Crossbeam: i-crossbeam ixhotywe nge-buckle yokukhusela ukukhusela ukuhambisa i-crossbeam;

Isitampu esimiliselwe iindawo: iindawo ezibunjiweyo ziqengqeleka ngokuzenzekelayo yifektri yethu, kwaye ukuqina kunye namandla abo ahlangabezana nemigangatho yoshishino yoMphathiswa woomatshini.

I-Heigris hegerls-izixhobo ezincedisayo kwi-beam pallet rack yendawo yokugcina impahla enemigangatho emithathu

I-Shelving: xhasa itreyi, yomeleza uzinzo kunye nokhuseleko lwetreyi. (i-i-span beam, i-i-span beam, i-i-span beam)

Tsala intonga: kubandakanywa ukutsalwa ngasemva, ukutsalwa kweshaneli, ukutsalwa kodonga, njl., Ukwandisa ukhuseleko kunye nokuzinza kweshelufu.

Abagadi bekona kunye nezithintelo zokuphahlazeka (enye kwababini): khusela ikholamu ukukhusela i-forklift ekubetheni ngengozi kwishelufu.

Izikhonkwane zokhuseleko, iibholiti kunye nezinye izincedisi: zixhotyiswe ngezikhonkwane ezipheleleyo zokhuseleko, iibholiti, izikrufu zokwandisa kunye nezinye izixhobo, ezinokomeleza umqadi ukuba ziwe, kwaye ziqinisekise ngcono ukusetyenziswa okukhuselekileyo kweeshelufu.

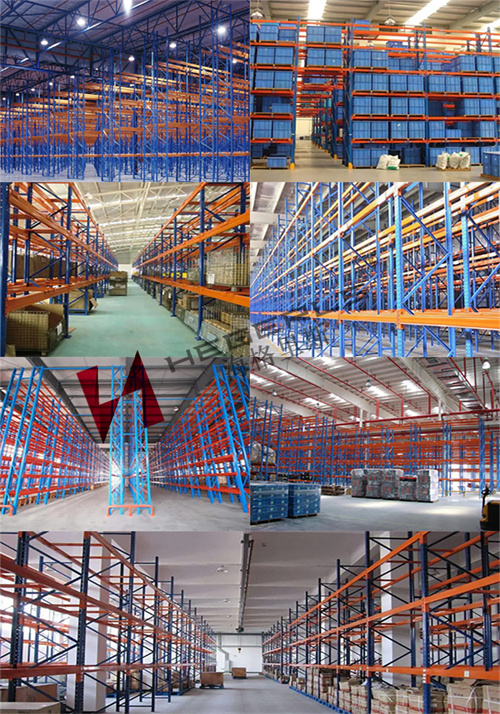

Isakhiwo sokubeka i-tray tray ilula kwaye inokwethenjelwa, enokulungelelaniswa kwaye idityaniswe ngokuthanda, kwaye ineempawu zomzuzu omkhulu we-inertia, umthamo oqinileyo wokulayisha kunye nokuchasana kwempembelelo enamandla. Umaleko ngamnye unokulayishwa ukuya kuthi ga kwi-5000kg/ umaleko phantsi koyilo olunxulumeneyo. Ayikhawulelwanga ngokulandelelana kwezinto ngaphakathi nangaphandle kwendawo yokugcina impahla, kwaye inokubunjwa ibe nkulu kakhulu. Iishelufu zokubunjwa, iishelufu ze-attic, iishelufu ze-warehouse ezintathu-dimensional, njl.njl nazo zingakhiwa ngokusekelwe kwiishelfu ze-tray, ezinokuthi zenziwe kwiishelufu ezikhethekileyo ze-oil barrel, njl. yokugcina kunye nokufikelela kwi-forklift. Ngokubhekiselele kwimbonakalo, inokuthintela i-forklift ukuba ingangqubani, kwaye inokunyusa i-column foot guards kunye ne-anti-collision rods. Ukuze uthwale umthwalo we-layer, unokuphinda ubeke inkxaso ye-beam, i-laminate, i-mesh cross beam kunye nezinye izibonelelo ezincedisayo kwi-beam. Xa amashishini ebeka le rakhi yokugcina inzima ukuba isetyenziswe, inokuphucula ngokufanelekileyo ukuphakama kwendawo yokugcina kunye nokuphucula izinga lokusetyenziswa kwendawo yokugcina impahla. Ineenzuzo zeendleko eziphantsi, ukufakwa kunye nokusebenza kakuhle, kulula ukufumana indawo, ilungele izixhobo zokuphatha, kwaye ifanelekile ukugcinwa kweentlobo ezahlukeneyo zeempahla.

I-Hagerls - izibonelelo ze-warehouse ene-dimensional-dimensional ene-crossbeam pallet shelf

Umthamo omkhulu wokuthwala kunye nomthamo olula: umthamo wokuthwala ngemitha yesikwele ungaphezulu kwe-300kg, enokufikelela ngokulula kwimfuno yakho ephezulu;

Ukuphuculwa kwendawo yokugcina impahla: iishelufu zinokudibaniswa kunye neeshelufu eziphambili kunye nezincedisayo, ukuphucula kakhulu indawo yokugcina, ukuququzelela ukugcinwa kwempahla, ukugcina irenti kunye nokuphucula ukusebenza kakuhle;

Ihlala ixesha elide: Ivenkile enkulu ithwele, igudileyo kwaye intle ukuwelda, inokumelana nokunxiba, ukumelana nokugqwala kunye nokuxhathisa umhlwa, kwaneyona ndawo ingaphantsi imanzi iyasebenza;

Inkqubo yokutshiza i-powder: ukugquma kuxinene, kunye nokubambelela kakuhle, amandla empembelelo kunye nokuqina, ukugubungela ikona ephezulu, ukuchasana nokugqwesa kweekhemikhali, kwaye ihlala intsha ixesha elide;

Ukwenziwa kwentsimbi epholileyo: qinisekisa ukuba ubukhulu bezinto eziphathekayo bufana kwaye umphezulu awunayo i-concave convex phenomenon;

I-Horizontal kunye ne-oblique yesebe ye-square tube design: inani elikhulu lamasebe anqamlekileyo liphakamisa ukunyanzeliswa kweqela lekholomu.

IHagerls - ithala leencwadi elinemigangatho emithathu linokusetyenziswa ngeendlela ezininzi

Ukudibanisa kunye neentsimbi zetsimbi: iipaliti zetsimbi zibekwe kwiishelufu ze-crossbeam, kwaye iipaliti zensimbi zicwangciswe kwiishelufu eziphezulu zokugcina iimpahla ezinzima, ezikhuselekileyo kunye neendleko.

Ukuhambelana nebhokisi yempahla ye-chuanzi kunye ne-tray yeplastiki: umaleko wokuqala wempahla ubekwe ngokuthe ngqo emhlabeni kunye nebhokisi yezinto eziphathekayo ukuqinisekisa ukuba iimpahla azichatshazelwa ngumswakama, kwaye uluhlu lwesibini nolwesithathu luxhotyiswe ngegridi e-I-shaped phantsi kweplastiki ye-chuanzi. itreyi.

Ukufanisa iplati yensimbi: ngokuqwalasela ukuba iinyawo zebhokisi lezinto eziphathekayo azikwazi ukuwela ngokuchanekileyo kwi-beam, isitya sentsimbi sibekwe kwi-beam ukuqinisekisa ukhuseleko.

Ngentsimbi edityanisiweyo yokudibanisa ipleyiti: iipleyiti zentsimbi zinokudityaniswa kwiigridi ezimbini ukwenza imiqadi yokutsala, esetyenziselwa ukuthwala iinyawo ezine zebhokisi yempahla, engaqinisekisi kuphela ukuba ibhokisi yezinto eziphathekayo inokuwela ngokukhuselekileyo kwi-shelf, kodwa igcina iindleko. .

Ukuhambelana nephalethi yomthi enamacala amabini: indawo ephezulu ye-6m idityaniswe nephalethi yeplanga enamacala amabini ukugcina iimpahla ezinemivalo. I-shelf ye-beam inomthwalo omkhulu, okhuselekileyo kwaye unokwethenjelwa.

Tshatisa negridi eslotyolweyo: yongeza igridi eqengqelekayo kumqadi ukwenza ipalethi yomthi ebekiweyo ikhuseleke.

Ukuhambelana nebhloko yegridi yeWang Zi: ukuba ukucaciswa kunye nobukhulu bepalethi ebekwe kwi-shelf ye-beam ayifani, kwaye umthwalo we-pallet awukwazi ukuhlangabezana nomgangatho wokusebenza okuphezulu, i-Wang Zi ibhloko yegridi inokongezwa.

Ukuhambelana nentsimbi yentsimbi kunye ne-pallet: i-bulk cargo kunye ne-pallet yokugcina idibene. Umgangatho ophantsi uhlanjululwe ngepleyiti yensimbi yokubeka imithwalo eninzi, kwaye umgangatho ophezulu uxhotyiswe ngepallet yokufikelela kwi-forklift.

Kwinkqubo yokusebenzisa iishelufu zokugcina, umphumo we-cross beam pallet shelves ubonakala kakhulu. Ixabiso layo lokusetyenziswa libonakaliswa ngokukodwa kumsebenzi okhethekileyo ngokudibanisa nobubanzi bomyalelo wendawo yokugcina impahla okanye isakhiwo esikhethekileyo, njl njl. Oku kunokuchaza ukuba iishelufu zephalethi ze-cross beam zinokuba lula ngakumbi ukugcinwa nokugcinwa kwempahla kwinkqubo yokusebenza yangempela. , yaye ukuguquguquka kwayo kukwanamandla ngokwentelekiso. Ngokubanzi, ixabiso lokusetyenziswa kweeshelufu zephalethi ye-cross beam libonakaliswe ngokwenene kumashishini amaninzi kwaye yamkelwa ngabathengi. Ukuguquguquka kwayo kunye nokuguquguquka kwayo kuye kwaphucula ngokufanelekileyo izibonelelo zoqoqosho lwamashishini ukuya kwinqanaba elithile, kwaye iishelufu nazo zisetyenziswe ngokubanzi kwiindawo zokugcina iimpahla eziphezulu.

Ixesha lokuposa: Jul-19-2022