Kwiminyaka yakutshanje, ngokuthandwa okuqhubekayo kwe-Intanethi, i-e-commerce iphuhliswe ngokukhawuleza. Iimpahla zoku-odola zabathengi zibonisa iimpawu zeentlobo ezininzi, iibhetshi ezimbalwa kunye nexesha elifutshane lokuziswa kwempahla, nto leyo eyenza ukuba ukuxinana kogcino lweeshelufa kwiziko lokuhambisa izinto zomniki kuqhubeke kuphucuka. Ubuninzi bezinto ezingenayo kunye nokuphuma kwindawo yokugcina impahla ziyanda. Inani leenxalenye ezincinci zokukha liyanda imihla ngemihla. Ayanda amaziko okuhambisa izinto asebenzisa isithuthi esisekwe kwiimoto kubantu abacholayo.

I-HEGERLS (i-Hebei Walker Metal Products Co., Ltd.

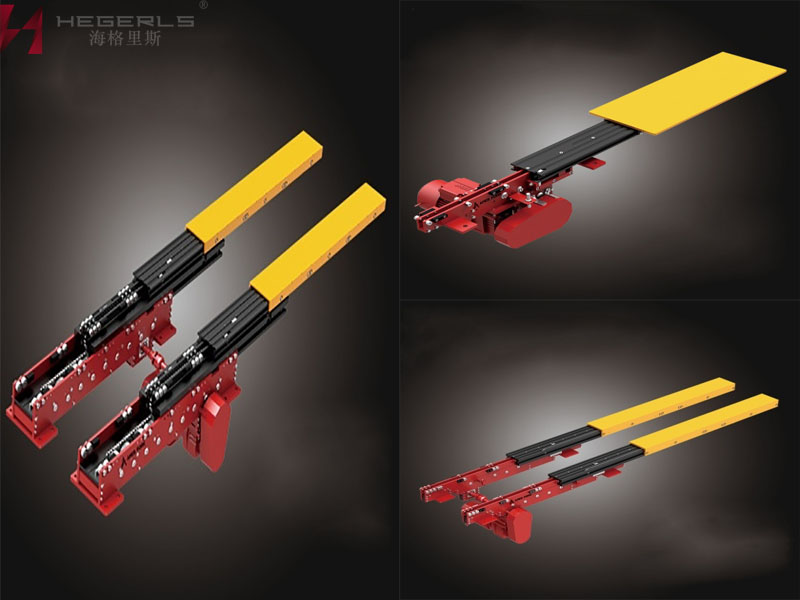

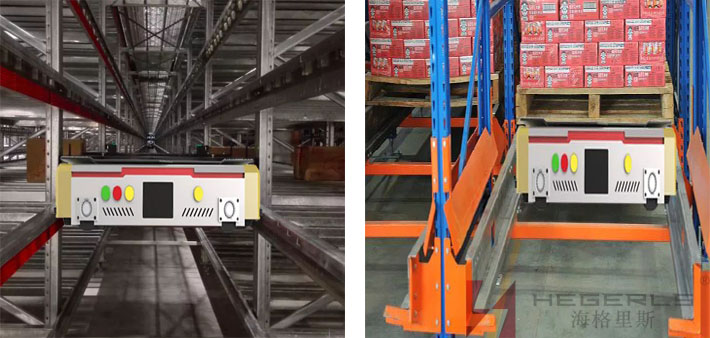

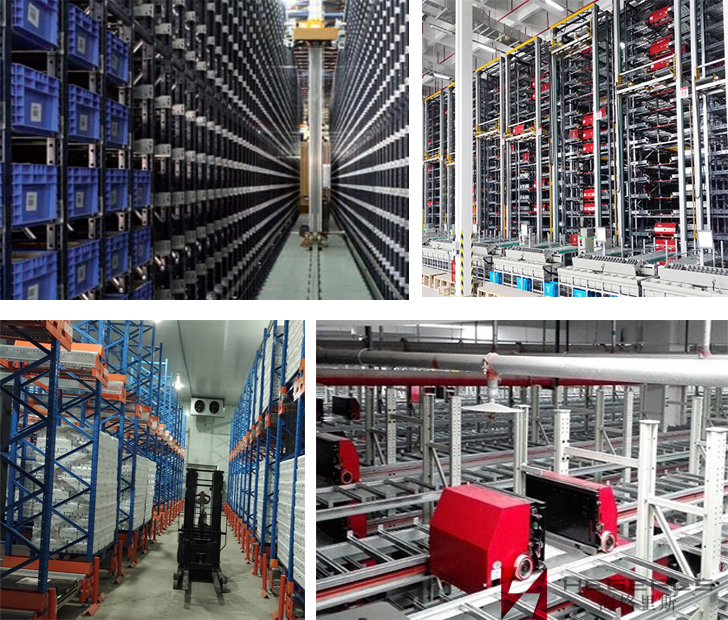

I-Clamping telescopic forks isetyenziswa ngokubanzi kwizixhobo zokugcina ezizenzekelayo ezifana ne-stereo warehouse multi-layer shuttle cars, i-shelf type bins AGV, RGV, kunye nomthwalo omncinci. Ubunzima obukhulu bebhokisi yezinto eziphathekayo ezigcinwe yi-HEGERLS zinokufikelela kwi-50Kg. Ububanzi be-clamping yengalo yefolokhwe bunokulungelelaniswa ngokungaqhelekanga ngaphakathi koluhlu lwe-200 ~ 600mm. Olona hambo luphezulu lokuchola yi-840mm. Esona santya siphezulu sokusebenza sefolokhwe yeteleskopu yi-1.5m/s, kwaye isantya yi-1.2m/s ². Ingxolo yokusebenza ilawulwa ngaphakathi kwe-75dB, enokuthi ihlangabezane neemfuno zeendawo ezininzi zokwandiswa kweerack kunye neziphindwe kabini. I-HEGERLS inokwenza ngokwezifiso i-multi-layer shuttle car stereoscopic warehouse yebhokisi yefolokhwe ye-telescopic ebambekayo ngokweemfuno ezithile zabathengi, njengobubanzi bokubamba, ukuchola istroke kunye nezinye iiparamitha.

Amalungu e-Hiygris HEGERLS abambe ibhokisi yefolokhwe yeteleskopu enemigangatho emininzi yokugcina imoto yesitiriyo Ifolokhwe yeteleskopu yindlela yeteleskopu esetyenziswa kwindawo yokugcina impahla kunye nenkqubo yogcino oluzenzekelayo yokugcina imathiriyeli okanye ukudluliselwa. Inomsebenzi wokwandisa okuzenzekelayo weendlela ezimbini kunye nomsebenzi ochanekileyo wokulinganisa! Inokuthi ifakwe ngokuthe ngqo kwi-stacker, okanye ifakwe kwindlela yokunyusa esisigxina, okanye ifakwe kwi-platform ye-mobile lifting platform. I-stacker ibaleka kwindlela phakathi kweeshelufa ukuze ifikelele ngokuzenzekelayo okanye idlulise izinto! Inokudityaniswa nenkqubo yomgca wemveliso kunye nenkqubo yolawulo lweshishini. Isebenzisa itekhnoloji yekhompyuter kunye nebhakhowudi (encoder) ukuqonda ulawulo kunye nokusebenza okukrelekrele!

Malunga HEGERLS Clamping Telescopic Fork

I-HEGERLS i-telescopic gripper fork luhlobo olukhethekileyo lwefolokhwe kuthotho lweefolokhwe zeteleskopu yezitaki, ezizezi, indlela ezimbini ezizenzekelayo zetelescopic gripper fork, eyaziwa ngokuba yifolokhwe yokubamba okanye ifolokhwe yokubamba, ifolokhwe yefolokhwe okanye ifolokhwe yefolokhwe. . Yifolokhwe ngokukodwa esetyenziselwa ukuhanjiswa kweebhinki ezincinci. Inokuhlanganiswa ngokuthe ngqo kwi-multi-storey picking AGV okanye ezinye iiplatifomu zokusebenza, kunye nokwandiswa kwengalo yefolokhwe kunye ne-clutch ye-lever (hook), Gcwalisa ukufikelela okanye ukudlulisa isenzo!

I-HEGERLS ifoloko yokubamba ininzi yenziwe nge-aluminium alloy, ebonisa ubungakanani obuncinci, ubunzima bokukhanya, isantya sokuhamba ngokukhawuleza kunye nokwandiswa okugudileyo. Kwangaxeshanye, ikwamkele umgaqo-siseko wongqamaniso lweemoto ezininzi, iqonda ukuba indlela enye yefolokhwe yeteleskopu inokusetyenziselwa ukudlulisa okanye ukufikelela kwiibhokisi zeenkcukacha ezahlukeneyo. Ayiphuculi ngokufanelekileyo kuphela ugcino olusebenzayo, kodwa ikwaphucula kakhulu izinga lokusetyenziswa kwendawo yokugcina, ngakumbi kwindawo yogcino oluphezulu olunobukrelekrele!

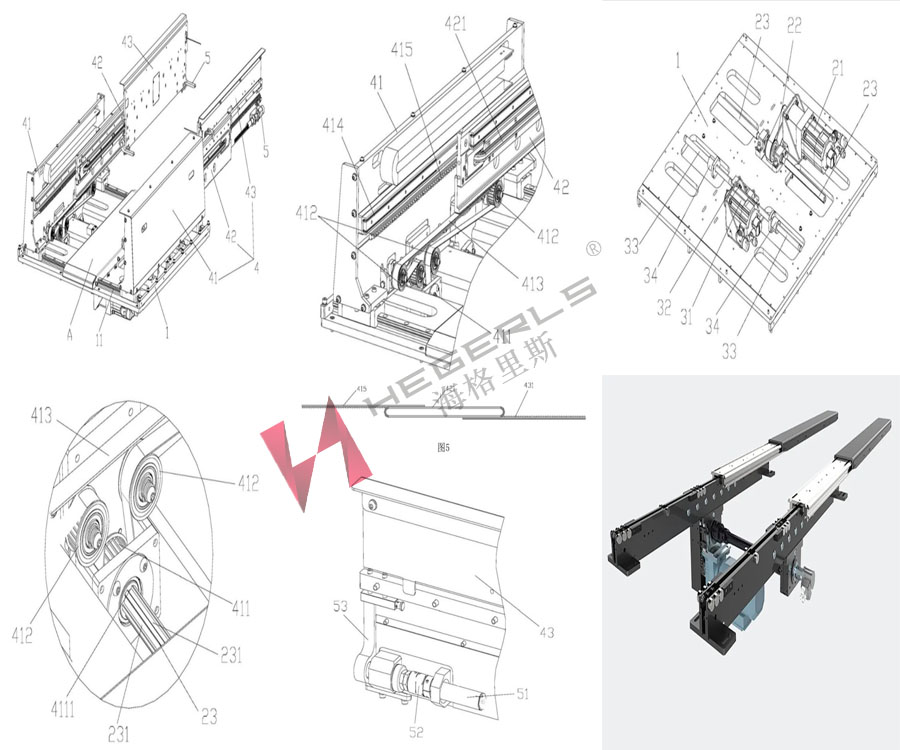

HEGERLS ikliphu kwisakhiwo sefolokhwe yetelescopic

Ubume be-HEGERLS ifolokhwe yokubamba inokwahlulwa ibe yindawo yokugcina enzulu kunye nendawo yokugcina enzulu. Indawo yokugcina enzulu yindawo yokugcina kunye neebhokisi ezimbini zezinto eziphathekayo, kunye nendawo yokugcina enzulu yindawo yokugcina kunye nebhokisi enye yezinto eziphathekayo. Oko kukuthi, indawo yokugcina enzulu inokubamba iibhokisi zezinto ezimbini ngexesha, ngelixa indawo yokugcina enzulu inokubamba ibhokisi enye yezinto ngexesha. Umahluko phakathi kwe-HEGERLS ifolokhwe yokubamba kunye nefolokhwe eqhelekileyo ye-telescopic ye-duplex kukuba ifolokhwe yokutsala ngomnwe isaqulunqwe ngamalungu amathathu efolokhwe, oko kukuthi, umzimba wefolokhwe yangaphakathi, umzimba wefolokhwe ephakathi kunye nomzimba wefolokhwe yangaphandle, ngaphandle kokuba umzimba wefolokhwe yangaphambili. inentonga enye yokutsala (ihuku), edityaniswa nesikhokelo sikaloliwe (isilayidi sikaloliwe), ibha yokuqengqeleka, ivili elilungelelanisiweyo, ibhanti elihambelanayo, ibhanti elithambileyo, intonga yokutshintsha (ihuku), i-jacking shaft, ibha yamavili, i-motor motor (servo) , i-shift rod motor Isixhobo sokubona kunye namanye amacandelo senza i-telescopic mechanism epheleleyo, esebenzisana nengalo yefolokhwe ye-telescopic kunye ne-clutch ye-lever (hook) ukugqiba ukufikelela okanye ukudlulisa isenzo!

Umgaqo osebenzayo we-HEGERLS ikliphu kwifolokhwe yeteleskophu

Ingalo yefolokhwe ye-HEGERLS ifolokhwe yokubamba isecaleni kwaye idityaniswe ecaleni ngomzila wesikhokelo. Ngolawulo, umzila wesikhokelo unokutyibilika umva naphambili ukulungisa umgama phakathi kweengalo ezimbini zefolokhwe yefolokhwe, ukuze kuphunyezwe ukusetyenziswa okuqhelekileyo kwefolokhwe kwiibhokisi zemathiriyeli eneenkcukacha ezininzi! Xa uthabatha izinto, ifolokhwe idlulela kwindawo yokugcina izinto, i-hook yokugcina (i-lever) iyancipha ngokuzenzekelayo kwaye ithintele isiphelo sobuso bebhokisi okanye ibhokisi yeplastiki, emva koko ifolokhwe ihoxisa, idonsa ibhokisi okanye ibhokisi yeplastiki phakathi ifolokhwe, kwaye emva koko iphuma ngasemva ngokweemfuno zesidanga, ikhonkco (i-lever) itsalwa ngasemva, kwaye ifolokhwe irhoxa kwakhona ukugqiba umsebenzi wokuchola okanye wokudlulisa! Nangona umgaqo wefoloko yokubamba ufana nefoloko ye-telescopic eqhelekileyo, iindawo zokuhambisa, izibonda zokudibanisa kunye nezinye iinxalenye zefoloko zomunwe zihluke kakhulu. Isetyenziselwa ukuchaza ukuba isondo lekhonkco, ikhonkco, i-gear, i-rack, njl., zonke zitshintshwa ngamavili ahambelanayo, amabhanti e-synchronous, njl., ngelixa i-sliding arm sliding rails , kunye nezixhobo zomzimba wefolokhwe zonke zitshintshwa ngamashiti esinyithi. okanye izinto ze-aluminium alloy, ngoko ubunzima befolokhwe yokubamba bumalunga ne-80kg kuphela.

Ukongeza, kufuneka kuqatshelwe ukuba ngexesha loyilo lwefolokhwe yohlobo lwe-telescopic yegripper, ubukhulu beeshelufu zokugcina ezixineneyo, indawo ethe nkqo yeeshelufa ezinebhokisi, inqanaba lomkhondo kunye nobukhulu beebhokisi kufuneka zidityaniswe ukugqiba iiparitha ezipheleleyo zeefolokhwe zokwandiswa (intshukumo yefolokhwe yokwandisa, isithuba sebhokisi, ububanzi befolokhwe, ububanzi bangaphakathi befolokhwe, ukuphakama kwefolokhwe, njl.), ukwenzela ukuhlangabezana neemfuno zemigqomo kwiishelufu. Ifolokhwe yokubamba inokudlulisa okanye ifikelele kuphela kwiimveliso ezipakishwe kwiibhokisi okanye kwiibhokisi zeplastiki ngokufanelekileyo, kwaye ayikwazi ukuhambisa imathiriyeli engaqhelekanga. Ukongezelela, umthamo kunye nobunzima bebhokisi yezinto ezidlulisiweyo akufanele zibe zikhulu kakhulu, kwaye ubunzima bomthwalo akufanele budlule i-100KG! Ukuphakama kwefolokhwe yokubambelela ngokuqhelekileyo kuyilwe ngokobude bomgqomo!

Malunga HEGERLS Clip kwi Shuttle

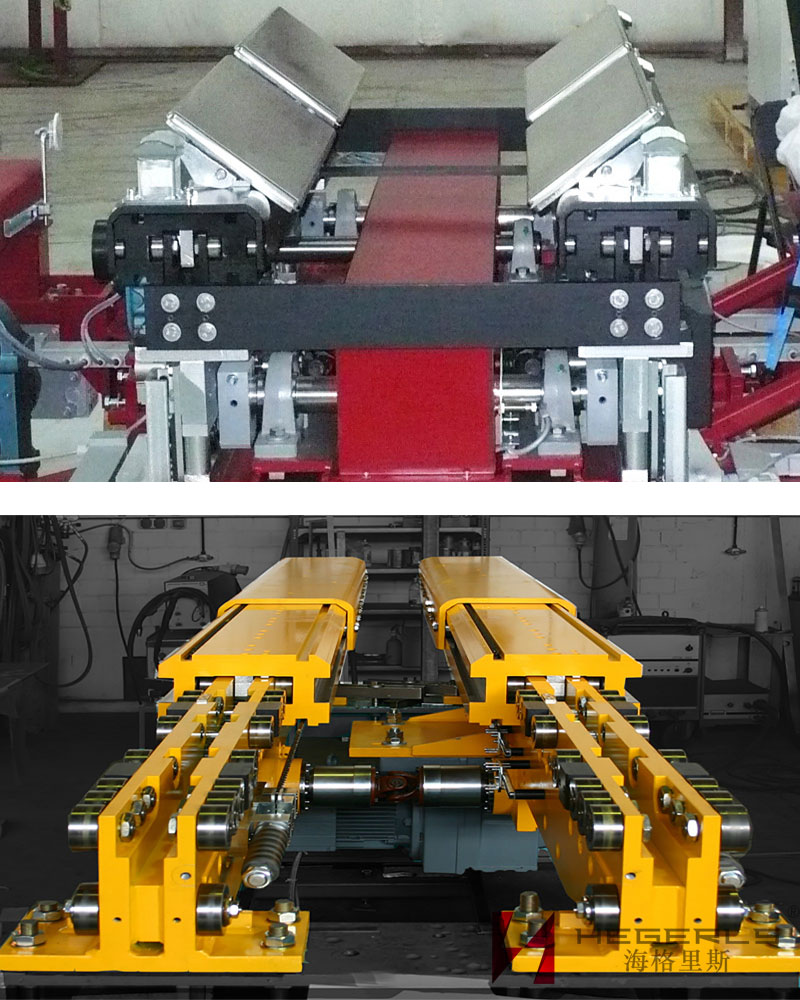

Ulwakhiwo lwekliphu ye-HEGERLS kwi-shuttle iquka isakhelo se-shuttle, i-shuttle chassis, indlela yokuhamba, indlela yokwandiswa kwefolokhwe yesibini, umqokeleli, ipleyiti yokuthwala kunye neqonga lokuthwala. Ulwakhiwo luhamba ngolu hlobo lulandelayo:

Nasiphi na isakhelo se-shuttle sikholisa ukuba ngumgodi ovaliweyo owenziwe zizibiyeli zomzimba eziphambili kumacala omabini, iqokobhe kunye ne-hub bracket yangaphakathi, kwaye icwangciswe ngokulandelelana kuzo zombini iziphelo ze-shuttle chassis; Iqokobhe libonelelwe ngesigqubuthelo esingaphezulu esinokuvulwa kwaye sivalwe ngehenjisi yocango lwenguqu; I-panel wire rack icwangciswe ngaphezu kwe-hub bracket; Umatshini wokuhamba uquka ivili lokuqhuba, ivili le-passive, i-DC brushless motor, i-reducer kunye ne-shaft yokudibanisa; Amacala omabini e-shuttle frame kwelinye icala le-shuttle chassis anikezelwa ngamavili okuqhuba axhunyiwe ngokudibanisa i-shafts, kunye namacala omabini e-shuttle frame kwelinye icala le-shuttle chassis linikezelwa ngamavili angenayo adityaniswe ngokudibanisa i-shafts; I-DC brushless motor isebenzisana ne-reducer ukuze iqhube ivili lokuqhuba kwaye iqhube ivili le-passive; I-shaft yokudibanisa inikezelwa nge-encoder magnetic, apho izikhundla zokuqala kunye nokumisa i-shuttle kwindlela echanekileyo zifunyenwe; Indlela yokwandiswa kwefolokhwe yesibini icwangciswe ngokulinganayo kwicala langaphakathi lesakhelo semoto yokuthutha; Ichassis yokuthutha phakathi kweendlela zokwandiswa kwefolokhwe yesibini ibonelelwe ngeqonga elithweleyo lokubeka ibhaskithi yempahla; I-cavity evaliweyo yefreyimu yemoto ye-shuttle inikezelwa ngokulandelanayo kunye neplate yokuthwala, apho i-plate yokuqhuba, i-plate yokulawula eyona ndlela yokuhamba kunye neplate yokulawula i-fork extension mechanism ihlelwe ngokulandelanayo; Ipleyiti yokuqhuba iqhuba indlela yokuhamba ukuze iqhube isiphekepheke ukubaleka kwindlela ethe tye. Ibhodi yolawulo oluphambili lwendlela yokuhamba ilawula iiparitha eziqhubayo kwaye iqalise iindawo zokumisa i-shuttle, kwaye ibhodi yolawulo ephambili yendlela yokwandisa ifolokhwe ilawula indlela yokwandiswa kwefolokhwe yesibini ukuze ibambe kwaye ibeke ibhasikidi kwi-shelf; Isixhobo sokuqokelela sibekwe phakathi kwemoto yokuthutha kunye nomzila othe ngqo, odibaniswa nocingo olunombane olulungiselelwe ngaphakathi kwendlela echanekileyo kwaye isetyenziselwa ukubonelela umbane wemoto yokuthutha. Uphawu lolwakhiwo lwekliphu kwimoto yokuthutha ekrelekrele ukuze igcinwe ikwindawo yokuba iigrooves zibekwe kwindawo apho ivili lokuqhuba kunye nevili eliqhutywayo ngokulandelelana linxibelelana neshaft yokuqhagamshela, kunye neringi yogcino olulastiki lubekwe kwigroove ukwenza i-axial. ukuma kwevili lokuqhuba kunye nevili lokwenziwa. Amavili esikhokelo aphindwe kabini abekwe ngokulandelelana kwicala le-shuttle chassis phantsi kwevili lokuqhuba kunye nevili lokwenziwa, naphakathi kwendlela ethe tye kunye ne-shuttle chassis. Amavili esikhokelo aphindwe kabini enza imida yasekhohlo nasekunene xa ivili lokuqhuba kunye nevili lokwenziwa libaleka kwindlela ethe tye. Indlela yokwandiswa kwefolokhwe yesibini ibandakanya: inqanaba lokuqala lefolokhwe yokwandisa ipleyiti yokutyhala, ipleyiti yolwandiso lwefolokhwe yenqanaba lesibini, inqanaba lesibini le-synchronous pulley mechanism, inqanaba lesibini lefolokhwe yokwandisa indlela yokuqhuba, ifolokhwe yokwandisa imoto, esinye isinciphisi, kunye neshaft yokuqhuba. ; Icala langaphandle le-hub bracket ye-shuttle car frame ibonelelwa ngesiteji sokuqala sefolokhwe yokwandisa i-push plate; I-chute emile okwe-U icwangciswe embindini weqonga lokuqala lefolokhwe yokutyhala ipleyiti, kwaye iipulleys ezininzi ezimilise u-U zicwangciswe ngezithuba ezilinganayo kwi-chute emilise u-U; Ipleyiti yefolokhwe yesibini icwangciswe ngaphandle kwe-chute efana ne-U; Ipleyiti yefolokhwe yesibini idityaniswe kunye neepulleys ezininzi ze-U-shaped groove ngokusebenzisa iibholithi kunye namantongomane; Iziphelo eziphezulu zenqanaba lesibini iplate yokwandisa ifolokhwe ngokulandelelana zibonelelwa ngefolokhwe yokutshintsha, i-DC planetary reducer motor kunye ne-photoelectric sensor evela ngaphandle ukuya ngaphakathi; I-sensor ye-photoelectric isetyenziselwa ukufumana isignali yendawo yefoloko kwaye uyithumele kwibhodi yokulawula ephambili yendlela yokwandiswa kwefolokhwe, elawula i-DC planetary reducer motor ukuqhuba ifoloko ukuba ihambe ngokuthe tye okanye ngokuthe nkqo; Umatshini wokutyhalela wesibini we-synchronous ulungelelaniswe ngokulandelelanayo kwipleyiti yokutyhala ifolokhwe kwaye ngokuthe ngqo ngaphantsi nangaphezulu kwe-chute emile okwe-U; Indlela yesibini ye-synchronous pulley mechanism idityaniswe ne-synchronous belt pressing plate kwiplate yokwandiswa kwefolokhwe yesibini; Ifolokhwe yokwandiswa kwemoto yemoto kunye nesinye isinciphisi siqhuba indlela yokuqhuba ifolokhwe yesibini yokuhamba, kwaye uqhube ifolokhwe yesibini yokwandiswa kwendlela yokuqhuba kwelinye icala ukuze uhambe nge-shaft yokuqhuba, ukuze ipleyiti yolwandiso lwefolokhwe yokuqala ihambe kwaye iqhube eyesibini. I-synchronous pulley mechanism yokuhamba, ngaloo ndlela iqhuba ipleyiti yolwandiso lwefolokhwe yesibini ukuba ihambe. Indlela yokuhambisa ifolokhwe enezigaba ezibini iquka i-encoder magnetic, i-synchronous belt pulley I, ibhanti ye-synchronous I, isixhobo sevili loxinzelelo kunye ne-rack; I-pulley yebhanti yexesha 1 kunye nebhanti lexesha 1 zicwangciswe ngaphantsi kwenqanaba lokuqala lefolokhwe yokutyhala ipleyiti; Elinye icala le-synchronous belt pulley I idityaniswe ne-shaft yokuhambisa, kwaye elinye icala lidityaniswe ne-shaft ephumayo yomnye umnciphisi ngendlela engundoqo. Izixhobo zevili le-tensioner zibekwe ngokulandelelana kumacala omabini esinye isinciphisi solungiso oluncedisayo lwe-synchronous ibhanti pulley I kunye nebhanti ye-synchronous I; I-rack icwangciswe phakathi kweqonga lokuqala lefolokhwe yokutyhala ipleyiti kunye nebhanti ye-synchronous; I-fork extension drive motor kunye nenye i-reducer iqhuba i-synchronous belt pulley I kunye nebhanti ye-synchronous I ukujikeleza, kwaye iqhube i-synchronous belt pulley II kunye nebhanti ye-synchronous II kwelinye icala ukujikeleza nge-shaft yokuhambisa. Kwangaxeshanye, iiracks kumacala omabini ziqhuba ipleyiti ehambelanayo yefolokhwe yokwandisa ifolokhwe ukufezekisa ukwandiswa kwefolokhwe yokuqala. Xa i-pulley yebhanti yesibini ehambelanayo ihamba ngolungelelwano kwaye iqhube ipleyiti yolwandiso lwefolokhwe yesibini ukuba ihambe, ipulley emile okwe-U iqengqeleka kwichute emile okwe-U, Yenza ipleyiti yolwandiso lwefolokhwe yesibini iqonde ukongezwa kwefolokhwe yesibini. Isixhobo ivili tensioning ibandakanya: bolt, isibiyeli uhlengahlengiso, nut kabini kunye tensioning ivili; Ivili loxinzelelo licwangciswe ngaphantsi kwebhanti ye-synchronous I kunye namacala omabini enye i-reducer, kwaye igxininiswe kwisibiyeli somzimba oyintloko ngokusebenzisa i-nut ephindwe kabini; Isibiyeli sokulungelelanisa sicwangciswa phantsi kwe nut ephindwe kabini ngebholiti, kwaye indawo yesibiyeli yohlengahlengiso ihlengahlengiswa yibholt, ukuze isibiyeli sokulungisa siqhube i-nati ephindwe kabini ukuba inyuke ihle, ukuze ibhanti le-synchronous ndikwazi ukugcina imeko yoxinzelelo phantsi kwentshukumo yevili loxinzelelo.

I-HEGERLS izakuqhuba njani iinzuzo zeshishini?

Okokuqala, indlela yokuhamba, indlela yokwandiswa kwefolokhwe kunye nesakhelo, umgca wokudibanisa kunye nesixhobo sokuqokelela amandla e-HEGERLS imoto ye-shuttle ehlakaniphile kunye nekliphu kwindawo yokugcina icwangciswe ngokufanelekileyo, eyenza ukusetyenziswa ngokupheleleyo kwendawo yemoto yokuthutha, kwaye inokulungelelanisa ukugcinwa okuzenzekelayo kunye nokufunyanwa kwempahla yemilinganiselo eyahlukeneyo kunye neendawo kwindawo yokugcina i-tatu-dimensional, ukwandisa ukugubungela isicelo semoto yokuthutha, kwaye ngokukhawuleza nangokufanelekileyo ukugqiba uthotho lwezenzo eziqhubekayo zemoto yokuthutha, njengokuhamba, ukwandiswa kwefolokhwe, ukuchola. phezulu kwaye ibeke iimpahla, Iqonda ugcino olukhawulezayo noluchanekileyo lweempahla, ngaloo ndlela iphucula kakhulu ukusebenza kakuhle kunye nenqanaba letekhnoloji ye-automation ye-warehouse ezenzekelayo, kunye nokunciphisa iindleko zotyalo-mali lwamashishini. Ngexesha elifanayo, ilula kwaye ilula kwisakhiwo, iphezulu ekuthembekeni, kwaye kulula ukuyigcina. Inokuthi ithathe indawo yesitaki sendlela yemveli, iqonde ukuguquguquka kwenkqubo, kwaye ihambelane nentsingiselo yophuhliso lolungiselelo lwe-e-commerce kunye ne-automation yokugcina.

Okwesibini, kwindlela yokuhamba ye-HEGERLS imoto ye-shuttle ehlakaniphile, i-shafts yokudibanisa yamavili okuqhuba kunye namavili ahambayo anikezelwa nge-grooves, kwaye iindawo ezidibanisayo zeebheringi zidibaniswe luhlobo olutsha lwendandatho yokugcina i-elastic, eqonda i-axial positioning effect yokudibanisa. iishafti Ngokusebenzisa i-elastic retainer ring ukufezekisa i-axial positioning effect, ukusebenza kakuhle kwemveliso kunokunyuswa kwaye iindleko zinokugcinwa.

Okwesithathu: I-Higelis HEGERLS imoto ye-shuttle ehlakaniphile yokubamba isitoreji iyaqonda ukuba isondo lokuqhuba kunye nesondo elijikelezayo lihlala lihamba ngendlela echanekileyo ngaphandle kokuphambuka kumzila ngokusebenzisa isakhiwo sevili lesikhokelo esiphindwe kabini. Esi sakhiwo sokumisa sizinzile kwaye sithembekile.

Okwesine, isakhiwo sokwandiswa kwefolokhwe yesibini esamkelwe yi-HEGERLS i-shuttle ehlakaniphile imoto inokwenza umgama wokwandiswa kwefolokhwe kude kwaye ufumane iibhasikithi ezininzi kwiindawo ezahlukeneyo; Ngexesha elifanayo, umgaqo wendlela yokwandiswa kwefolokhwe yesibini ilula, kwaye iindleko zokuyila kunye nokuveliswa ziphantsi; Inxalenye yothumelo yamkela imowudi yemoto enye + yokunciphisa + ishafti yokuhambisa ukwenza indlela yesibini yokwandiswa kwefolokhwe ifikelele kwinjongo yokwandiswa okuhambelanayo kunye nokucutha, okugcina iindleko ezingaphezulu, ukunciphisa ngokufanelekileyo indawo yokubeka efunekayo, kunye nokunciphisa ubunzima bemoto yokuthutha. .

Okwesihlanu, i-Higelis HEGERLS imoto ye-shuttle ehlakaniphile ithatha uhlobo olutsha lwesixhobo sevili loxinzelelo, olunokukhawuleza ukugcina ibhanti ye-synchronous tensioned kwaye iqonde umsebenzi oqhelekileyo wemoto yokuthutha. Ngaphezu koko, esi sixhobo sevili loxinzelelo silula ukwenza, sikulungele ukuyifaka kwaye sinokuhlengahlengiswa ngokukhawuleza, okonga iindleko, ukonga indawo kunye nokuphucula ukusebenza kakuhle.

Ixesha lokuposa: Dec-19-2022