Ngophuhliso olukhawulezayo lwesikali seshishini, amashishini amaninzi andise iindidi zeempahla kunye neshishini elinzima. Imowudi yolawulo olubanzi lwemveli kunzima ukufikelela kulawulo oluchanekileyo. Xa kudityaniswa nokunyuka kweendleko zabasebenzi nomhlaba, ukuzenzela kunye nobukrelekrele bokugcina impahla nazo ziyavela. Kwiminyaka yakutshanje, iintlobo ngeentlobo zeerobhothi kunye nezisombululo ziye zaziswa ngokuthe ngcembe emarikeni, phakathi kwayo indawo yokugcina iimoto eshukumayo kunye nestacker stereoscopic warehouse, njengeyona ndlela yokugcinwa kwepallet automated stereoscopic warehouse, nayo iye yatsala ingqalelo engakumbi kunye nokusetyenziswa. Ngoko ke yintoni umahluko phakathi kweendlela ezimbini zokugcina iimpahla? Amashishini angalukhetha njani uhlobo logcino olufanelekileyo? I-Hebei hegris hegerls umenzi weshelufu yokugcina i-shelf ilungelelanise kwaye yabelane ngeemeko ezifanelekileyo kunye neempawu zokugcinwa kweemoto zokuthutha kunye ne-stackers!

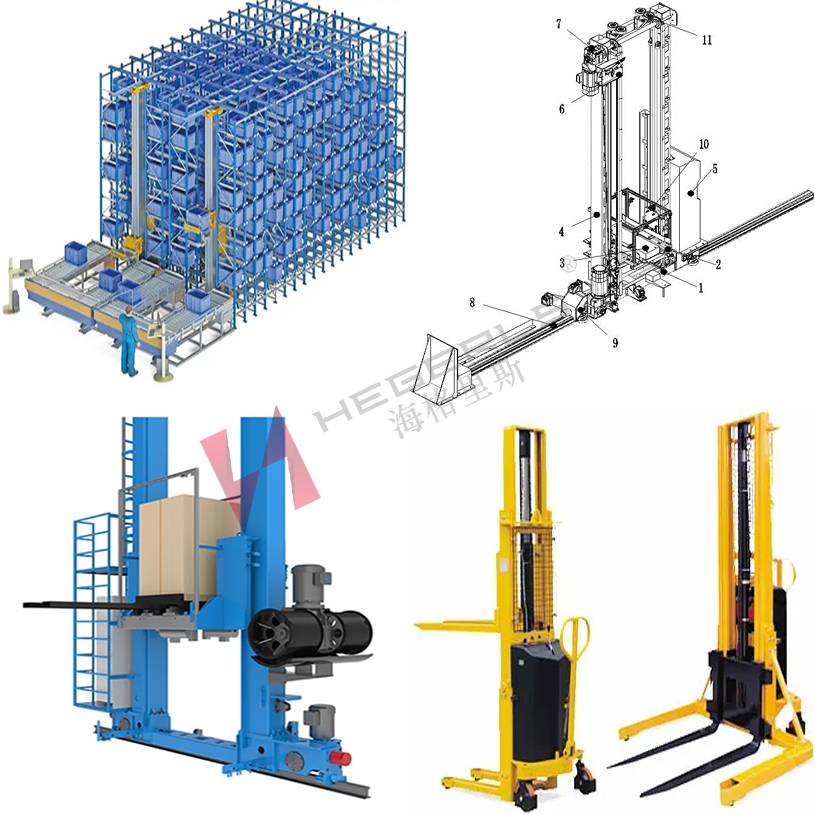

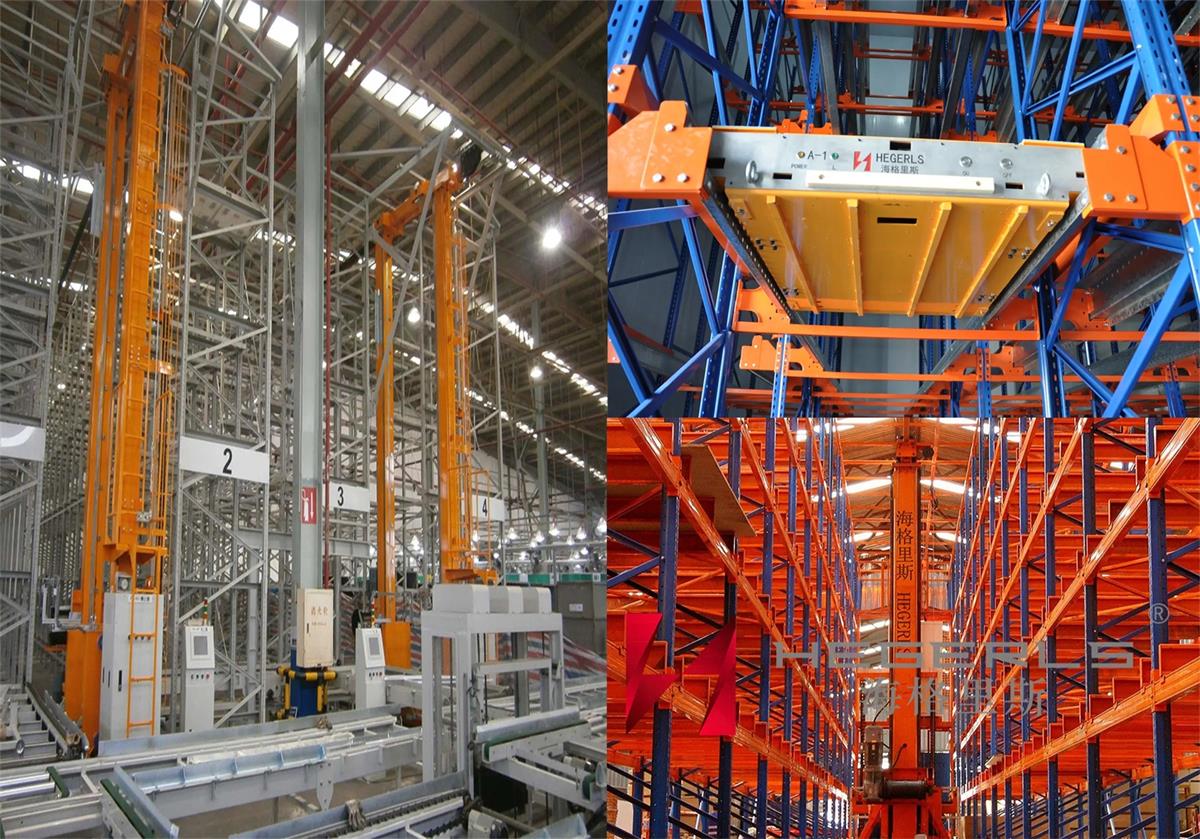

Stacker

Umsebenzi ophambili we-stacker kukugijima umva naphambili kumgca we-warehouse ene-dimensional-dimensional, ukugcina iimpahla kwindlela yokuwela kwigridi yempahla yeshelufu, okanye ukukhupha iimpahla kwigridi yeempahla kwaye uzithuthe ukuya. indlela yokunqumla. Ngokusebenzisa intsebenziswano yesakhiwo soomatshini, inqwelo inokuhamba ngokukhululekileyo kwindlela emithathu yokulungelelanisa kwitonela.

Uncedo olulodwa lwe-stacker:

1) Ukuphucula ukusetyenziswa kwendawo yokugcina

I-stacker incinci ngobukhulu kwaye inokugijima kwindlela kunye nobubanzi obuncinci. Kufanelekile ukusebenza kweshelufu kunye nokuphakama komgangatho ohlukeneyo kunye nokuphucula izinga lokusetyenziswa kwendawo yokugcina impahla;

2) Ukusebenza kakuhle okuphezulu

I-Stacker sisixhobo esikhethekileyo sokugcinwa kwee-dimensional ezintathu. Inesantya esiphezulu sokuphatha kunye nesantya sokugcinwa kwempahla, kwaye inokugqiba umsebenzi wogcino ngexesha elifutshane;

3) Uzinzo olusebenzayo

Oomatshini bokupakisha kunye nezixhobo banokuthembeka okuphezulu kunye nokuzinza okulungileyo xa usebenza;

4) Iqondo eliphezulu lokuzenzekelayo

Kwinkqubo yogcino lwangoku olukrelekrele, i-stacker inokulawulwa kude. Uninzi lwee-stackers zilawulwa zizixhobo zokulawula ngokuzenzekelayo. Oku kungenxa yokuba i-stacker ixhotyiswe ngezibonelelo ezixhasayo ezifana nenkqubo yokufunda nokubhala ye-RFID, inkqubo ye-bar code induction kunye neteknoloji yerediyo. Ngokusebenzisa inkqubo yokufunda nokubhala ye-RFID, inkqubo yokufakwa kwekhowudi yebha ngokuchanekileyo ibeka ulwazi lwezinto eziphathekayo kunye nezinye iziqulatho kwindawo nganye yokugcina impahla, kwaye emva koko isebenzisane nomyalelo wokuthunyelwa kwenkqubo yolawulo lwe-warehouse (WMS), Yenza ukudluliselwa okuchanekileyo kunye nokusebenzayo kwezinto. , ukwenzela ukuba inkqubo yokusebenza iyonke ingabinamntu kwaye ilungele ukulawula ukugcinwa.

Isitshixo se-RGV

Imoto yothutho sisixhobo sothutho esikrelekrele, esinokucwangciswa ukuqonda imisebenzi yokuchola, ukuthutha kunye nokubeka, kwaye inokunxibelelana nenkqubo yolawulo lwendawo yokugcina impahla (WMS) ukuqonda inkqubo yokusebenza ngokuzenzekelayo ngokudibanisa iRFID, ikhowudi yebha kunye nezinye. itekhnoloji yokuchonga.

Izixhobo zemoto ezitshixayo zinokuqonda ukugcinwa kwempahla ngokuzenzekelayo kunye nokubuyiswa, utshintsho lwendlela oluzenzekelayo kunye nokutshintsha umaleko, kunye nokunyuka ngokuzenzekelayo. Inokuthuthwa kwaye iqhutywe phantsi. Sisizukulwana samva nje sezixhobo zokuphatha ezikrelekrele ezidibanisa ukupakisha okuzenzekelayo, ukuphatha ngokuzenzekelayo, isikhokelo esingenamntu kunye neminye imisebenzi. Inokuguquguquka okuphezulu. Inokutshintsha indlela yokusebenza ngokuthanda kwayo, kwaye ilungelelanise umthamo wenkqubo ngokunyusa okanye ukunciphisa inani leemoto ezizithutha. Ukuba kuyimfuneko, inokulungelelanisa ixabiso eliphakamileyo lenkqubo kwaye ixazulule i-bottleneck yokungena kunye nokuphuma kwimisebenzi ngokuseka imo yokucwangcisa i-flood fleet.

Iimeko zesicelo kunye neempawu zokugcina ze-RGV shuttle kunye ne-stacker zifaniswa ngolu hlobo lulandelayo:

1) Ishelufu yesicelo

Iimoto ezishuthayo ziqhele ukusetyenziselwa iishelufa ezishinyeneyo ezizihambelayo; I-stacker iya kusetyenziselwa iishelufu ezizenzekelayo ezimxinwa zetshaneli ezinokuphakama okuphezulu.

2) Iimeko ezisebenzayo

Iimoto ezishuthayo zisebenza ngokubanzi kwiindawo zokugcina iimpahla ezingaphantsi kwe-20m, kwaye zingasetyenziswa kwiikholamu ezininzi kunye neendawo zokugcina iimpahla ezingaqhelekanga; I-stacker ifanelekile kwiindawo zokugcina eziphezulu kunye nezide kwaye zifuna ukucwangciswa okuqhelekileyo.

3) Umthwalo

Umthwalo olinganisiweyo ngokubanzi we-shuttle ungaphantsi kwe-2.0T; Umthwalo we-stacker uphezulu. Ngokubanzi, umthwalo olinganisiweyo yi-1T-3T, ukuya kuthi ga kwi-8t okanye ngaphezulu.

4) Ukusebenza kakuhle

Imoto ye-shuttle yeyezixhobo ezininzi ezidibeneyo zokuthutha, kwaye ukusebenza kakuhle kwendawo yokugcina impahla kungaphezulu kwe-30% ephezulu kune-stacker; I-stacker yahlukile. Yeyemowudi yokusebenza komatshini omnye, kwaye ukusebenza kwayo kunciphisa ukusebenza kakuhle kogcino.

5) Ubuninzi bokugcina

I-stacker ithatha indawo enye enzulu kunye noyilo oluphindwe kabini, kwaye umlinganiselo wevolumu wempahla unokufikelela ngokubanzi kwi-30% ~ 40%; Imoto yokuthutha iyakwazi ukuyila ubunzulu ngokohlobo lwezixhobo, kwaye umlinganiselo weploti unokuba phezulu ukuya kuma-40% ~ 60%.

6) Ukuguquguquka

Enyanisweni, umzimba wemoto ye-shuttle unokuhamba ngeendlela ezine, kwaye unokufikelela kuyo nayiphi na indawo yempahla yendawo yokugcina impahla. Inokuguquguquka okunamandla. Imoto nganye inokuxhasana, ukuze kufezekiswe uqwalaselo olufanelekileyo; Kwi-stacker, i-stacker nganye inokugijima kuphela kumzila osisigxina.

7) Ukunyuka kade

Ekwakhiweni kwendawo yokugcina izinto ezintathu-ntathu, inani leemoto zokuthutha linokunyuswa ngokwemfuno kamva; Nangona kunjalo, i-stacker ayinakuguqulwa okanye inyuswe okanye iyancipha emva kokuba ulungelelwaniso olupheleleyo lwe-warehouse lwenziwe.

8) Ukuthelekisa iindleko

Ngokuqhelekileyo, ixabiso eliqhelekileyo lendawo enye yokugcina iimoto ezihamba ngeemoto zingaphantsi kwe-30% kunezitaki; Nangona kunjalo, iindleko zokwakhiwa kwendawo yokugcina impahla ye-stacker iphezulu, ubuninzi bendawo yokugcina impahla incinci, kwaye ixabiso eliqhelekileyo lendawo enye yomthwalo liphezulu.

9) Umngcipheko wokulwa

Iimoto ezishuthayo, zonke izikhundla zokungaphumeleli komatshini omnye aziyi kuchaphazeleka. Ezinye iimoto zingasetyenziselwa ukutyhala iimoto ezingaphumelelanga ngaphandle kwendlela, kwaye iimoto ezithuthayo zezinye iileyile zinokugqithiselwa kuluhlu olungaphumeleliyo ukuqhubeka nomsebenzi; Isitaki, ukusilela komatshini omnye, indlela yonke iyama.

10) Ingxolo yokusebenza

Imoto ye-shuttle inikwe amandla yibhetri ye-lithium. Ubunzima bayo bunzima kwaye ukusebenza kwayo kuthe cwaka kwaye kuzinzile; Ubunzima be-stacker bukhulu, ngokubanzi i-4-5t, kwaye ingxolo ngexesha lokusebenza inkulu.

11) Inqanaba lokusetyenziswa kwamandla

Iimoto ezishuthayo zihlawuliswa ngokusebenzisa imfumba yokutshaja. Imoto nganye yokuthutha isebenzisa imfumba yokutshaja enegunya lokutshaja i-1.3KW, eya kudla i-0.065kw ngexesha elinye ngaphakathi nangaphandle kwendawo yokugcina impahla; Kwi-stacker, umgca woqhagamshelwano we-sliding usetyenziselwa ukunikezelwa kwamandla. Isitaki ngasinye sisebenzisa iinjini ezi-3, kwaye amandla okutshaja angama-30kW. I-stacker idla i-0.6kw ukugqiba ixesha elinye ngaphandle / kwindawo yokugcina.

12) Ukhuseleko lokhuseleko

I-stacker inomzila osisigxina kunye nonikezelo lwamandla ngumgca woqhagamshelwano we-sliding. Ngokuqhelekileyo, akuyi kubangela ukusilela lula kukhuseleko; Nangona kunjalo, imoto ye-shuttle ihamba kakuhle ngexesha lomsebenzi, kwaye umzimba wayo uthatha iindlela ezahlukeneyo zokukhusela, ezifana noyilo lokukhusela umlilo, umsi kunye noyilo lwe-alamu yokushisa, ngokuqhelekileyo ayiyi kubangela ukungaphumeleli kokhuseleko lula.

Enyanisweni, ngokwembono yokuthelekisa, akunzima ukuba sibone ukuba, njengendlela yokugcina ehlakaniphile yendabuko, i-stacker ingene kwishishini lemarike ngaphambili kwaye inamava aqolileyo. Nangona kunjalo, ngophuhliso oluqhubekayo kunye nokutsha kweteknoloji, kunye neenzuzo zokuguquguquka, ukusebenza kakuhle, ukuxinana, ubukrelekrele, ukonga amandla kunye nokunye, i-hegris hegerls shuttle ngokuthe ngcembe iba yinto eqhelekileyo. Ukuba ukugcinwa kokusebenza kakuhle kwendawo yokugcina impahla kufuneka ibe phezulu, kwaye iimpahla kufuneka zihanjiswe kwaye ziphume ngokukhawuleza, iingenelo ze-stacker zibonakala ngakumbi. Nangona kunjalo, ukuba iindleko kufuneka zilawulwe okanye ubude betshaneli nganye bufutshane, kufaneleka ngakumbi ukukhetha iimoto zokuhamba. Nangona kunjalo, kwiprojekthi yokwakhiwa kwendawo yokugcina kunye nokulungiswa, umenzi we-shelf ye-Hercules hegerls kufuneka kwakhona akhumbuze ukuba kuyimfuneko ukudibanisa izinto ezahlukeneyo ukukhetha izisombululo ezifanelekileyo zokugcina ngokwemiqathango yendawo.

Ixesha lokuposa: Jun-06-2022