Ngenguqu ekhawulezileyo kunye nokuphuculwa kwemizi-mveliso yasekhaya neyangaphandle, amashishini amaninzi nangakumbi kufuneka aphucule ulwazi lwawo lothutho, kodwa ahlala ethintelwa ziimeko ezisebenzayo ezinjengendawo yokugcina impahla, ubude, imilo, kunye nezinto zokungaqiniseki kwintengiso. Ke ngoko, xa kuthelekiswa notyalo-mali kwiindawo zokugcina iimpahla ezizihambelayo ezinemigangatho emithathu, amashishini atyekele ngakumbi ekukhetheni iinkqubo zolungiselelo olunamanqanaba aphezulu obukrelekrele kunye nokuguquguquka. Inkqubo ye-shuttle yendlela emine yeepallets iye yaba yinkqubo ethandwayo ezenzekelayo kunye nenkqubo yokugcina kakhulu kwimarike ngenxa yokuguquguquka kwayo, ubukrelekrele kunye nezinye izibonelelo.

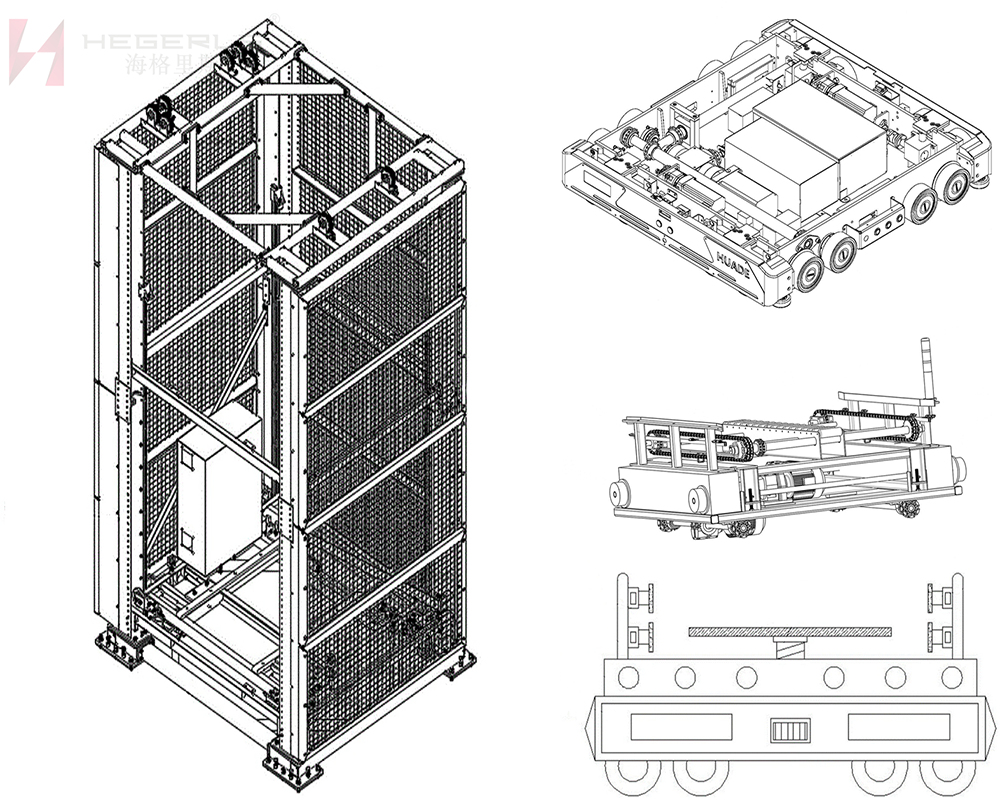

I-pallet yeendlela ezine ze-shuttle yenzelwe kwaye iphuculwe kwisakhiwo sendlela ezimbini zokuhamba. I-pallet ye-shuttle yeendlela ezimbini inokufezekisa imo "yokuqala, kuqala" okanye "indlela yokuqala, yokuqala" xa ithatha iimpahla, kwaye isetyenziswa kakhulu kumashishini anobuninzi kunye neentlobo ezimbalwa. Kodwa ngophuhliso oluqhubekayo lwemarike, imfuno yeebhetshi ezincinci kunye nezininzi ziyanda. Okwangoku, ngenxa yezinto ezifana nokusetyenziswa komhlaba kunye neendleko eziphezulu zabasebenzi, imfuno yokusetyenziswa kwendawo kunye nokugcinwa okunzulu ngamashishini kuya kungxamiseka ngakumbi. Kulo mongo, i-tray-way-shuttle izithuthi ezinokuthi zifezekise ukugcinwa kwe-dense, ukusetyenziswa kwendawo, kunye nokucwangciswa okuguquguqukayo kuye kwavela. Njengenye yeendlela ezintsha zokugcina iimpahla, i-monster yeshelufu ixhotyiswe ngeengoma ezibalekayo, kwaye uhlobo lwepallet yemoto yendlela emine ye-ASRV inokusebenzisana ngokukhululekileyo kunye nokuguquguquka kunye ne-elevator ukuphumeza ukugcinwa kunye nokuchola iimpahla nakweyiphi na indawo enemigangatho emithathu. .

Njengenye yamashishini asekhaya asekuqaleni ukungena kuphando kunye nophuhliso kunye nokuveliswa kwezixhobo zemoto ye-shuttle, i-Hebei Woke Metal Products Co., Ltd. (i-brand ezimeleyo: i-Hegerls) ibandakanyeke kuphando kunye nophuhliso lweemveliso zeemoto ezihamba phambili ukususela kwi-1998. Ukuza kuthi ga ngoku, iimveliso zayo zeemoto ezizithutha ziye zagubungela uthotho olwahlukileyo olunje ngetreyi yohlobo lwemoto yohlobo lwemoto, uhlobo lwebhokisi yemoto eneendlela ezimbini, uhlobo lwebhokisi yemoto eneendlela ezine, uhlobo lwetreyi yendlela ezimbini, uhlobo lwetreyi yeemoto ezine. , i-attic type shuttle car, njalo njalo. I-tray-way shuttle yenye yeemveliso ezingundoqo uHebei Woke egxininisa ekwakheni. Olu hlobo lwezixhobo luneenzuzo eziphezulu kumsebenzi wogcino oluxineneyo, iimpawu zokwandisa eziguquguqukayo, kwaye zifanelekile kwiindlela zokusebenza ezineenkcukacha ezininzi zemveliso kunye neebhetshi ezimbalwa.

I-Higris intelligent tray ye-four-way isithuthi sisisombululo esiguquguqukayo esijikeleza ukugcinwa kwetreyi kunye neemeko zokuphatha. Abasebenzisi beshishini banokudibanisa ukuguquguquka njengoko kufuneka, njengeebhloko zokwakha. Ngexesha elifanayo, inokuphinda ifezekise umsebenzi "wesithuthi esinye esiqhuba yonke indawo yokugcina impahla", kwaye inokulungelelanisa inani lezithuthi ngokweenguqu kwimfuno ngexesha lexesha elide kunye nokukhula kweshishini. Okwangoku, inkqubo yeHagrid tray ye-four-way shuttle system iphunyeziwe kwezinye iindawo zokugcina. Ngokwedatha yokulinganisa yangempela evela kwishishini lokuvelisa izinto eziluhlaza, phantsi kwendawo yokugcina impahla, ukusebenzisa iskimu se-crane ye-stacker sinokufumana indawo yokugcina i-8000, ngelixa ukusebenzisa isicwangciso sesithuthi seendlela ezine sinokufumana indawo yokugcina i-10000, ukwandisa ukusetyenziswa kwendawo ngaphezu kwe-20% . Ngaphezu koko, i-hagrid tray ye-four-way shuttle nayo ineenzuzo ezilandelayo:

Okokuqala, ukuguquguquka okuqinileyo: Oku kubonakaliswa ikakhulu kukuziqhelanisa nesakhiwo somzi-mveliso. Ukusetyenziswa kwee-cranes zemveli ze-stacker ngokuqhelekileyo kulwakhiwo lweendawo zokugcina ii-rectangular, ngelixa ii-shuttle-way-shuttle cars zingakhiwa ngendlela yemodyuli nakwiifektri ezingaqhelekanga.

Okwesibini, itekhnoloji ibhetyebhetye kakhulu kwaye inokuqina okugqwesileyo: xa kuthelekiswa neendawo zokugcina iimpahla ze-stereoscopic ezizenzekelayo ezithintelwa yi-stackers, izithuthi ezineendlela ezine ziguquguquka ngakumbi kwaye zinokusebenzisa izithuthi ezininzi kwitonela, ngaloo ndlela kuphuculwe izinga lokungena kunye nokuphuma kwetonela. .

Okwesithathu, iimoto ezihamba ngeendlela ezine zisebenza ngamandla kwaye zinobuhlobo nokusingqongileyo: ngokwembono yomthamo womthwalo kunye nomlinganiselo wobunzima bokuzimela, iimoto ezinendlela emine zineenzuzo ezipheleleyo. Iikhrayini zemveli zinobunzima obungaphezulu kweetoni ezilishumi ukutsala itoni enye yeempahla, ngelixa iimoto ezihamba ngeendlela ezine zinobunzima obungamakhulu eekhilogram kwaye zinokutsala itoni enye yeempahla, oko kukhokelela kusetyenziso oluphantsi lwamandla.

Okwesine, kukho indawo enkulu yokuphucula kwikamva letekhnoloji yendlela emine: malunga nokucwangciswa kwezithuthi kunye nolungelelwaniso phakathi kwezithuthi kunye neelevator, ngokusekwe ekuphuculweni kwe-algorithms yobukrelekrele bokwenziwa, kukho indawo eyongezelelekileyo yokuphucula kwiyunithi yeyunithi yemveliso yexesha. kwisikhephe ngasinye seendlela ezine kwixesha elizayo.

Ngeli xesha, iinkampani ezininzi zixhalabile kakhulu malunga nomba wesantya. Ngokubhekiselele kwisantya, i-Hercules tray-way-way shuttle inokufezekisa isantya sokubuyisela i-2.5S kwiimeko ezingalayishwanga kunye ne-3.5S kwiimeko ezilayishiwe, eziphuculweyo eziphawulekayo xa kuthelekiswa nezinye iimveliso kwishishini. Kwiimeko eziqhelekileyo zokumisa izithuthi ezinendlela emine, iHagrid iye yaphucula ukukhawuleziswa komzimba wesithuthi, ngesantya esingalayishwanga ukuya kuthi ga kwi-2m/s2.

Inkqubo yeHagrid ezine-shuttle system inokudityaniswa nezinye izisombululo ezifana neerobhothi ezizihambelayo ezizihambelayo, iirobhothi eziphalelisa, kunye neendawo zokusebenzela ezibonwayo. Ngokomzekelo, kwiprojekthi yempahla, ngaphezu kwe-80 yeendlela ezine izithuthi ezisetyenzisiweyo kwaye zinokwenza ibhokisi epheleleyo yokukhetha ngaphezu kwe-10000 SKU kunye namashumi amawaka eendawo zokugcina.

Ixesha lokuposa: Feb-26-2024