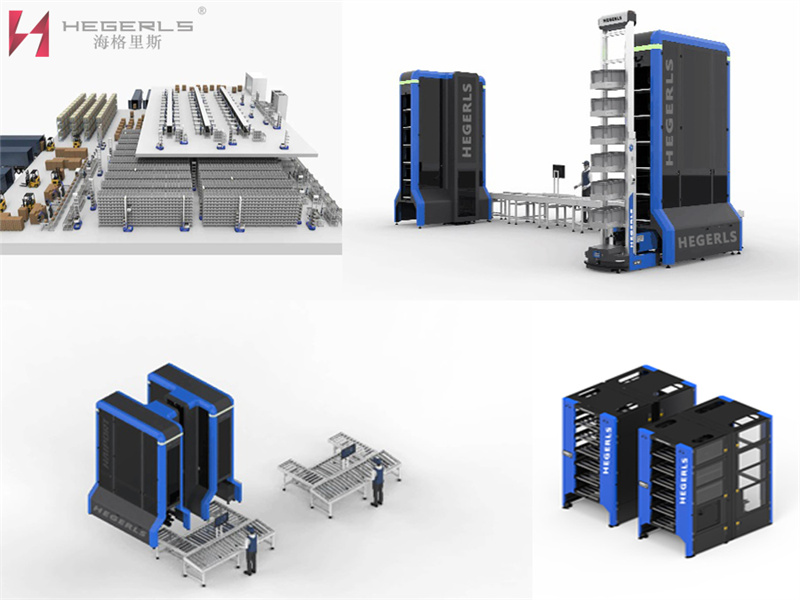

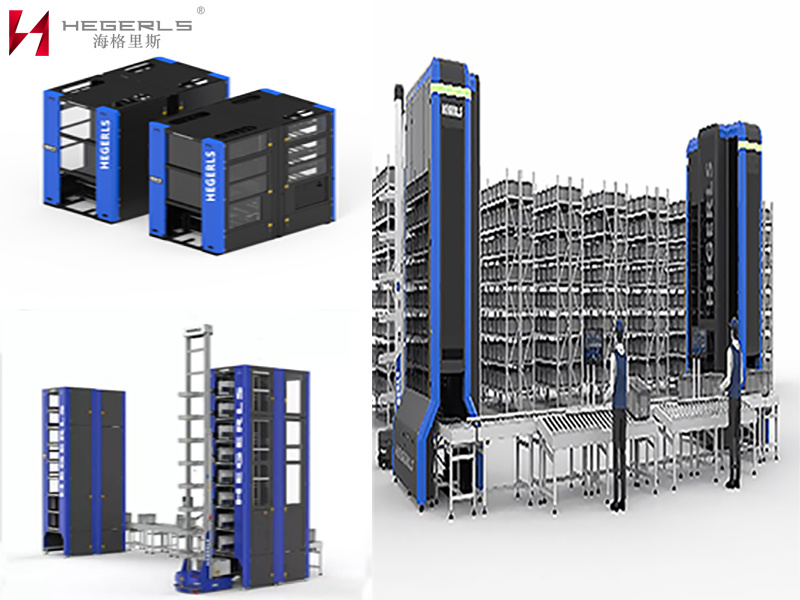

Kwiminyaka yakutshanje, ngokunyuka kokunqongophala kobutyebi bomhlaba kunye nokunyuka kweendleko zomntu, ukuphuculwa kwe-automation ye-warehousing kunye ne-logistics industry isoloko ithatha "ukunciphisa iindleko kunye nokuphucula ukusebenza kakuhle" njengento ephambili ephambili. Kwiminyaka yakutshanje, izixhobo zokugcina iimpahla kunye nezixhobo ezizenzekelayo ziye zavela ngokungapheliyo, kodwa abaqhubi be-warehouse bahlala benentlungu: kunzima ukuqwalasela ukusebenza kakuhle kunye neendleko. Ngokujonga le ngongoma yentlungu, iqela le-hegerls le-hegris, elinokunciphisa ukuthunyelwa kweerobhothi nge-30%, ukunciphisa iindleko zabasebenzi nge-66%, kunye nokuphucula ukusebenza kakuhle kokuhlelwa ngamaxesha angama-3-4, ibandakanyeka kakhulu kwintsimi yebhokisi. inkqubo yerobhothi yokugcina. Isebenza ngokukhethekileyo kwi-hegerls yokulayisha ngokuzenzekelayo kunye noomatshini bokukhuphela kwirobhothi ye-kubao, ichaza indlela entsha yokusebenzisana phakathi kwempahla kunye nabantu, kwaye iphucula ngakumbi ugcino olusebenzayo. I-Higgins hegerls ukulayisha okuzenzekelayo kunye nothulo lomatshini wokusebenzela umatshini kwakhona ubhukuqa indlela yokunxibelelana yempahla ebantwini, kwaye idibanisa iimpawu zokuphatha izikhongozeli ezininzi ezisebenzayo ze kubao ukuqonda ukulayishwa kunye nokothula izikhongozelo ezininzi, kuphucula kakhulu ukusebenza kakuhle kogcino kunye nogcino.

I-hegerls i-othomathikhi yokulayisha kunye nokukhupha umatshini wokusebenzela umatshini iqulethwe ngumatshini wokulayishwa kunye nokukhulula, umgca wokuhambisa, i-Kanban ebonakalayo, udonga lwembewu, kunye nenkqubo yokuhlela ukukhanya. Idityaniswe neerobhothi ze-Kubao ukukhulula ngokuzenzekelayo, ukuhambisa, kunye nokulayisha ibhokisi yemathiriyeli ukusuka kwingobozi yangasemva yerobhothi, ukuze kuqatshelwe ugcino oluzenzekelayo kunye nomsebenzi wokothula. Indawo yokusebenzela inomthwalo osebenzayo wokulayisha kunye nokukhupha, onokugqiba ukulayishwa kwee-container ezi-6 kwi-3S kunye nokuthuthwa kwee-container ezi-6 kwi-5S, ukuphucula kakhulu ukusebenza kwe-robot; Uyilo lwemodyuli, bhetyebhetye kwaye kulula ukuhamba, ukuxhasa ukunyuka okukhawulezayo / ukuncipha kwezixhobo, kunye nokuhlangabezana neemfuno zokusebenza kakuhle kunye neendleko; Abasebenzi bohlulwe kwiirobhothi ukuqinisekisa ukhuseleko; Ngokoyilo lwe-ergonomic, i-console yokuchola ineenzuzo zobuntu, ukusebenza kakuhle, ukusebenza kakuhle okuphezulu ngaphakathi nangaphandle kwendawo yokugcina, njl njl. Imeko esebenzayo: yonke imeko iyasebenza, ngakumbi imeko enenani elikhulu lezinto ezigciniweyo kunye nokukha. .v

Imigaqo yoyilo ye-hegerls yokulayisha ngokuzenzekelayo kunye nokukhulula umatshini wokusebenzela:

Njengemveliso ene-ETL kunye ne-CE certification, i-haggis yokulayisha ngokuzenzekelayo kunye nomatshini wokukhulula uphumelele iimvavanyo eziqinileyo ngokubhekiselele kukhuseleko lomatshini, ukhuseleko lombane, ukhuseleko olusebenzayo, ukhuseleko lomlilo, ukhuseleko lomsebenzi kunye nempilo, ukuqinisekisa ukuthembeka kwemveliso;

*Imisebenzi yokhuseleko isekwe kwimigaqo yoyilo yomgangatho we-ISO 12100 ukunciphisa umngcipheko;

*Inkqubo yokulawula yenzelwe kwaye yenziwe ngokuhambelana neemfuno ze-iec/en 60204-1 kunye ne-ISO 13849-1, kunye nezixhobo zokhuseleko (i-interlock switch, i-stop stop emergency) zijongwa ngokugqithiswa kokhuseleko kwaye zisebenza kuphela phantsi kweemeko ezikhuselekileyo. Inqanaba lokusebenza lokhuseleko lifikelela kwi-PL D;

*Uyilo lwephaneli yokulawula kunye nebhentshi yokusebenza ihambelana ne-ergonomics;

*I-HMI (i-interface yomatshini womntu) i-interface yomatshini womntu idityaniswe kwikhabhinethi yombane kwaye ibekwe ngaphandle kwendawo enobungozi ukukhusela nayiphi na ingozi enokubonwa kwangaphambili;

*Umnyango wonke womatshini wesixhobo uxhotyiswe ngesixhobo sokukhusela uqhagamshelo, kwaye ucango lokuvula ucango lucinyiwe. Umatshini unokuphinda uqalise ukusebenza kuphela emva kokuba ucango lomatshini lonke luqhele ukuvalwa. Ukhuseleko lwabasebenzi bezolondolozo luqinisekisiwe kwinqanaba elikhulu, kwaye umngcipheko wokhuseleko uyancipha kakhulu;

*Isistim yokuphakamisa yenzelwe ukumelana nesiphoso esinye kwaye ikhuselwe kwimingcipheko ehambelanayo ngamacwecwe avaliweyo avaliweyo kunye nezixhobo zokukhusela ezidibeneyo;

*Izixhobo ezingundoqo zokhuseleko ziya kuba zizixhobo ezithobelayo ezihlangabezana neemfuno zemigangatho yaseMelika neyaseYurophu.

Umgaqo osebenzayo we-hegerls isikhululo sokusebenza esizenzekelayo:

Izikhongozeli zicholwa kwaye ziphathwe yirobhothi kubao, edityaniswe ne-hegerls automatic loader workstation. Ukothulwa kwezikhongozeli ezininzi kubonwa kwi-5S, kwaye izikhongozeli zibuyiselwa kwi-hegerls i-automatic loader workstation emva kokuhlelwa. Izikhongozeli zilayishwa kwi-3S, ebonisa ugcino olusebenzayo kunye nenkqubo yogcino. I-hegerls ukulayisha okuzenzekelayo kunye nokukhulula umatshini wokusebenzela umatshini ukwaxhasa ukufakwa kwe-docking kunye ne-manipulator ukuqonda ukuhlelwa kwempahla, ukudala ukuzenzekelayo kwayo yonke inkqubo yokungena kunye nokuphumayo, kunye nokuphucula ngakumbi ukusebenza kakuhle kwemisebenzi yokugcina impahla.

Iimpawu ezisebenzayo ze-hegerls i-automatic loader workstation:

*Esebenzayo kwaye iyakhawuleza-isantya sokulayisha i-3S, isantya sokukhulula i-5S

I-hagerls indawo yokusebenza yomatshini wokukhuphela ngokuzenzekelayo iphuhliswe ngokukodwa kwaye iyilelwe kubao irobhothi. Ezi zimbini ziqhagamshelwe ngobukrelekrele ukuqonda ukulayishwa kunye nokothula izikhongozeli ezininzi. Irobhothi nganye inokugqibezela ukulayishwa kweekhonteyina ezi-6-8 ngexesha elinye kwimizuzwana emi-3 kuphela kunye nokukhulula ngemizuzwana emi-5. Xa kuthelekiswa nendawo yokusebenzela umgca wokuthutha, isantya sokulayishwa kunye nokukhulula i-robot siphindwe ka-16 ngaphezulu.

*Ukunciphisa iindleko kunye nokunyuka ngokufanelekileyo-ukuphucula ukusebenza kwerobhothi enye ngama-30%

Isisombululo sokugcina esihlakaniphile esisekelwe kwi-robot ye-kubao inokunyusa ubuninzi bokugcinwa kwe-80% - 130% kunye nokuphucula ukusebenza kakuhle kwendawo yokugcina impahla ngamaxesha angama-3-4. Ngentsebenziswano kunye ne-hagerls yokulayisha ngokuzenzekelayo kunye nokukhulula umatshini wokusebenzela, i-robot ye-kubao inokulayisha ngokuzenzekelayo kwaye ikhuphe izikhongozeli, iqonde ukulayisha (ukukhulula) kunye nokuhamba, kunye nokusebenza kakuhle kwerobhothi kunokunyuswa ngama-30%. Ngexesha elifanayo iyunithi, irobhothi inokugqiba imisebenzi yokuodola ngakumbi, ifezekise ukuphuculwa kwe-30% ekusebenzeni kakuhle kwenkqubo, kwaye indawo yokugcina impahla iyasebenza ngakumbi.

*Imeko yeshishini eliguquguqukayo-ukushukuma okuguquguqukayo, utshintsho olukhawulezayo lwendawo yokufaka, ukuqina okunamandla

Isitishi sokusebenza sokulayisha iihagerls samkela uyilo lwemodyuli kwaye sixhasa ukumiswa koluhlu olupheleleyo lweerobhothi ze kubao. Inguqulelo elungiselelweyo ye-hagerls i-automatic loader workstation inokulayisha / ikhuphe ukuya kuthi ga kwizikhongozeli ezisi-8 ngaxeshanye. I-hegerls yokulayisha ngokuzenzekelayo kunye nokukhupha umatshini wokusebenzela unokutshintsha ngokuguquguqukayo indawo yayo, kwaye iguqule ngokuguquguqukayo inani leendawo zokusebenza kunye neengqungquthela ezisekelwe kwiimeko zoshishino, ezikufutshane neemeko zoshishino.

*Ukunciphisa ngokufanelekileyo iindleko zokusasazwa okuzenzekelayo

Intsebenziswano egqibeleleyo phakathi kwe-robot ye-Kubo kunye ne-hegerls yokulayisha ngokuzenzekelayo kunye nokukhulula umatshini wokusebenzela umatshini unokunciphisa ngokufanelekileyo iindleko zokuthunyelwa kwe-automation ye-warehousing. Ngaphantsi kweemeko ezifanayo, ukucwangciswa kwe-hegerls ukulayishwa ngokuzenzekelayo kunye nokukhupha umatshini wokusebenzela kunokunciphisa inani leerobhothi, ukuphucula ukusebenza kakuhle kokugcinwa kunye nokukhulula, kunye nokunciphisa ngokufanelekileyo iindleko zokwakhiwa kwakhona kwendawo yokugcina.

*Isikhongozeli esikhuselekileyo kwimowudi yomntu

"Isikhongozelo kumntu" esisebenzayo esibonelelwa yi-hegerls yokulayisha ngokuzenzekelayo kunye nokukhulula umatshini wokusebenzela udale indlela entsha yomthwalo kwintsebenziswano yomntu. Uyilo lwendawo yokusebenzela ye-hegerls ezenzekelayo ihambelana ne-ergonomics kwaye iphucula induduzo yokusebenza ngesandla. Iimpahla zinokukhethwa ngesandla kwindawo echongiweyo yeqonga lokusebenza ukuphepha ukunxibelelana ngokuthe ngqo nerobhothi kunye nokuqinisekisa ukhuseleko lokusebenza.

*I-docking eguquguqukayo yezixhobo ezahlukeneyo

Kwiimeko ezahlukeneyo zokusetyenziswa, i-hegerls i-othomathikhi yokulayishwa kwendawo yokusebenzela ixhasa ukugoba okuguquguqukayo kwezixhobo ezahlukeneyo: i-hegerls i-othomathikhi yokulayisha i-workstation inokulungiswa kunye nezikhundla zokusebenza zezandla ezininzi ukugqiba ukuhlela imithwalo kunye nokuphucula ngakumbi ukusebenza "komgqomo kumntu"; Isenokuthi idityaniswe neengalo zoomatshini kunye nezinye izixhobo ukuqonda ukuhlenga ngokuzenzekelayo kunye nokuphucula ukusebenza kakuhle.

*Unxibelelwano olunobuhlobo phakathi kwabantu nekhompyuter-iibhokisi ezingama-900 / ugcino lweyure ngokufanelekileyo, ukuphucula ukusebenza kakuhle kokukhetha ngesandla ngamaxesha angama-2-3;

Ngokweemfuno zeshishini elithile, i-haggis ibonelela ngoyilo lwesikimu esilungiselelweyo. Ukusebenzisa i-hegerls yokulayisha ngokuzenzekelayo kunye nokukhulula umatshini wokusebenzela umatshini, ukusebenza kakuhle kwendawo yokugcina impahla kunokufikelela kwiibhokisi ezingama-900 ngeyure, nto leyo ephucula kakhulu ukusebenza kakuhle kunye nokuphucula ukusebenza kakuhle kokucholachola ngama-2-3 amaxesha.

Ixesha lokuposa: Jul-08-2022