Ukuzuza kuphuhliso olukhawulezayo lwe-e-commerce, kukho imfuno eyomeleleyo yokugcinwa kwezinto ezizenzekelayo ngaphakathi ngaphakathi nangaphandle. Ngokukodwa kwiminyaka yakutshanje, ngokuchasene nokunyuka kweendleko zabasebenzi, iindawo zokugcina ezinkulu ezahlukeneyo kunye namaziko okuhlela ekhaya naphesheya ziye zandisa iinzame zazo kulwakhiwo oluzenzekelayo lwendawo yokugcina iimpahla. Kulo mxholo, izisombululo ezisekelwe kwi-tray ezinokufikelela kwindawo yokugcina, ukusetyenziswa kwendawo, kunye nokucwangciswa okuguquguqukayo, ubukhulu becala kunye neenqwelo-moya ezine-shuttle ezihlakaniphile, sele ziqalile ukuvela kwindawo yokugcina izinto ezikrelekrele.

Kumxholo wamashishini emveliso, njengoko amashishini ezinto ezibonakalayo ejongene nemingeni efana nokwahluka kwemfuno, ukuzaliseka kolungelelwaniso lwexesha lokwenyani, kunye nemodeli yeshishini elikhawulezayo lokuphindaphinda, iimfuno zabathengi kwizisombululo zolungiselelo zithanda ukuba bhetyebhetye kwaye zibe nobukrelekrele. Ngokusekelwe kulo mkhwa, u-Hebei Woke uye wasungula i-pallet ye-Hagrid HEGERLS ehlakaniphile ye-shuttle yeendlela ezine, egcwalisa i-gap kwizisombululo eziguquguqukayo kwintsimi yokuphatha i-pallet ngaphambili. Kwimarike yanamhlanje, iishelufu zepallet ziye zaba lolona hlobo luqhelekileyo lweeshelufa zokugcina ezisetyenziswa kwiindawo zokugcina iimpahla zale mihla, amaziko othutho, amaziko okuhambisa, kunye nezinye iimeko.

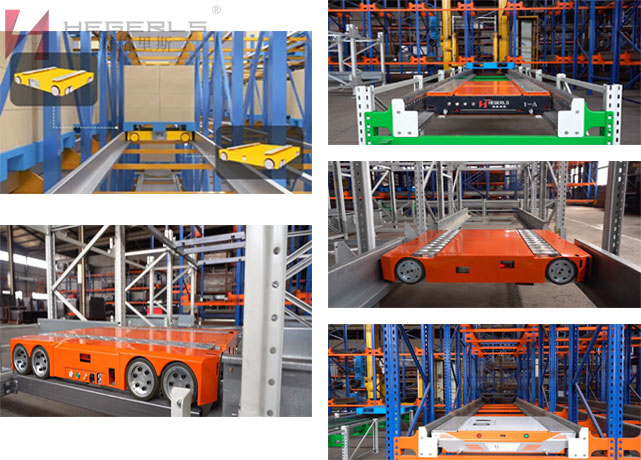

I-Hagrid HEGERLS i-tray ehlakaniphile ye-four-way-shuttle car iquka i-four-way shuttle car, i-hoist ezinikeleyo, i-shelf system, i-accessory system (kubandakanywa nesikhululo sokutshaja, ukuhanjiswa, i-remote control, inethiwekhi, kunye nenkqubo yokulawula umbane) HEGERLS inkqubo yesoftware yokucwangcisa. Ngenxa yokubandakanyeka kokucwangciswa kwezithuthi ezininzi kunye nomsebenzi wobambiswano kunye nezixhobo ezinxulumeneyo ezifana nezinyusi kwi-tray yendlela yemoto yendlela emine, ukukwazi ukucwangcisa isoftware kuya kuba nefuthe elibalulekileyo ngokuthe ngqo ekusebenzeni kakuhle kwenkqubo. IHagrid HEGERLS uhlobo lwetreyi ekrelekrele yohlobo lwe-4-way shuttle ineengenelo ezintandathu eziphambili: “ultra-thin”, “ultra fast”, “ultra safe”, “long unyamezelo”, “super big-scale-scale cluster schedule”, enokuphucula kakhulu. ukusebenza kakuhle kwemveliso yamashishini. Le robhothi izimele ishukumayo enokuthi iqhube ezishelufini inokuphucula ngakumbi izinga lokusetyenziswa kwendawo yokugcina impahla ngama-30% xa kuthelekiswa nezisombululo zendalo ezizisebenzelayo. Kwangaxeshanye, i-HEGERLS itreyi ekrelekrele enendlela emine yemoto inomzimba oziimilimitha ezingama-125 kuphela, inobunzima obungama-300 eekhilogram, kwaye ixinene kwaye yomelele. Iyakwazi ukuphatha izinto ezinobunzima be-1 ukuya kwi-1.5 yeetoni, okwenza kube lula ukusebenza. Xa kuthelekiswa ne-10 toni stacker, inokugcina ngaphezulu kwe-50% yombane. Xa kuthelekiswa nezisombululo ze-automation zendabuko, umzimba oguquguqukayo unokuhamba phakathi kweeshalofu, ukwandisa zombini isantya sokusebenza kunye nobuninzi bokugcina, okwenza kube yinto efanelekileyo kakhulu yokugcina ibanda, amandla amatsha kunye nezinye iimeko zokusebenza.

I-Hagrid HEGERLS i-tray ehlakaniphile ye-4-way-shuttle solution ayiyona inkqubo yokugcinwa kwe-dense elula, kodwa isisombululo sokugcina esinengqiqo kunye nesiguquguqukayo. Inzuzo yayo engundoqo ilele kulawulo olusasazwayo lwezixhobo ezidityanisiweyo. Kungenxa yolu phawu ukuba abasebenzisi kunye namashishini banokudibanisa kwaye basebenzise njengoko kufuneka, njengeebhloko zokwakha. Ngokungafani ne-AS / RS stackers, enokuthi isebenze kuphela kwiindlela ezimiselweyo, inkqubo yezithuthi ezine ilungelelaniswa ngenxa yemveliso yayo ye-hardware, enokutshintshwa ngemoto entsha nangaliphi na ixesha xa kukho ukungasebenzi kakuhle. Okwesibini, ukuguquguquka kubonakaliswa "kwi-scalability eguquguqukayo" yenkqubo yonke, apho abasebenzisi kunye namashishini anokonyusa okanye anciphise inani leemoto ezineendlela nangaliphi na ixesha ngokotshintsho olunje ngokukhula kwexesha kunye nokukhula kweshishini, ngaloo ndlela kuphuculwe inkqubo yezithuthi. umthamo wokuthwala. Ukongeza, izixhobo ezidityanisiweyo zihambelana ngokusondeleyo nokucwangciswa kunye ne-algorithms, ngelixa ulawulo olusasazwayo lukhona ngokwenene kwisithuthi ngasinye, esihambelana ne-AMR yokulawula iteknoloji yeqonga. Isicwangciso sokucwangciswa kwe-HEGERLS asikwazi ukulawula kuphela isithuthi ngasinye seendlela ezine, kodwa kwakhona ukubonelela ngee-algorithms zokutshintsha umthamo ongenayo kunye nokuphumayo, ukunikezelwa kwamandla okuthutha, ukulungiswa kwendawo yokugcina indawo, kunye nokulungiswa kwendlela. Ngokuphathelele ukucwangciswa kwezixhobo ezicacileyo okanye ukuphuculwa kokusebenza kakuhle kwenkqubo, obona buchule bukhulu buvela kwisoftware, eyona nto iluncedo kuluhlu lweemveliso zeHagrid. Ukongeza, i-Hagrid HEGERLS itreyi ekrelekrele enendlela emine yothutha inezi zibonelelo zilandelayo:

1) Ulawulo oluhlakaniphile

Ukuphucula ngokufanelekileyo ugcino lwempahla kunye nokusetyenziswa kwendawo yokugcina impahla. Ukudityaniswa kwesoftware ye-WMS kunye ne-WCS kunye ne-ERP yeshishini, i-SAP, i-MES kunye nenye isoftware yenkqubo yolawulo inokugcina kwakhona okokuqala, kulawulo lokuqala lwempahla kunye nokuphelisa ukudideka okanye ukusebenza kakuhle kwezinto zabantu ekusebenzeni.

2) Ukutshintshela umaleko okrelekrele

Ukusebenzisana ne-elevator, imoto ye-shuttle inokufezekisa imo yokusebenza esebenzayo yokutshintsha okuzenzekelayo kunye nokuchanekileyo; Qwalasela ukusebenza kwesithuba esi-ntathu-ntathu. Ukulawula ngokuchanekileyo ukungena kunye nokuphuma kwendawo nganye yokugcina ngaphakathi kwendawo yeshelufu yensimbi.

3) Ulawulo lweeNdawo eziDynamics

Iindawo zokugcina iimpahla zemveli ziindawo nje zokugcina iimpahla, kwaye ukugcinwa kwempahla ngumsebenzi wabo kuphela, oluhlobo "lokugcina i-static". I-pallet ye-shuttle ye-four-way sisixhobo sothutho esihamba phambili esizenzekelayo esingavumeli kuphela ukuba iimpahla zigcinwe ngokuzenzekelayo kwaye zigcinwe kwindawo yokugcina impahla ngokweenkcukacha ezifunekayo, kodwa zinokudityaniswa ngokwemvelo kwiinkqubo zokuvelisa ngaphandle kwendawo yokugcina impahla. Ukuququzelela ukusekwa kweenkqubo zolungiselelo oluphezulu nokuphucula inqanaba lolawulo lwamashishini.

4) Ukuphucula ngokufanelekileyo ukusetyenziswa kwendawo yokugcina

Uxinaniso oluphantsi logcino lweendawo zokugcina iimpahla zemveli lukhokelela ekusetyenzisweni okuphantsi kwendawo epheleleyo kunye nendawo yokugcina impahla. Iloli ye-pallet ye-shuttle yeendlela ezine ihamba ngeendlela ezine kumzila oyintloko ngaphakathi kweshelufu, kwaye inokugqiba ngokuzenzekelayo ukusebenza ngaphandle kokulungelelaniswa kwe-forklifts kunye nezinye izixhobo. Ngenxa yomthamo wengoma ephambili yeshelufu incinci kunomthamo wejelo le-forklift yokusebenza, i-pallet yendlela emine ye-shuttle automation system iphucula ngakumbi ukusetyenziswa kwendawo yokugcina xa kuthelekiswa nenkqubo eqhelekileyo yeshelufu yelori, inokunyusa malunga ne-20% ukuya kwi-30%, eyi-2-5 amaxesha e-warehouse eqhelekileyo;

Njenge "isizukulwana esitsha se-pallet flexible logistics solution", i-HEGERLS i-pallet ehlakaniphile ye-shuttle yendlela emine, idibene ne-software ye-HEGERLS ye-software, inokufikelela kwi-swarm intelligence kwaye isebenzise kakhulu indawo yokugcina indawo yokugcina impahla. Ukongezelela, i-pallet ye-Hagrid HEGERLS i-pallet ehlakaniphile ye-shuttle yeendlela ezine iya kulungiselelwa ngokwe-SKUs ezahlukeneyo kunye neendawo zokugcina, kwaye i-algorithm iya kucebisa ngokuzenzekelayo iindawo zokugcina ezifanelekileyo xa izinto zigcinwe kwindawo yokugcina impahla, evumela ukuba iimpahla zigcinwe ngokwemigaqo ethile kwaye ukuphepha ukuxinana ngexesha lemisebenzi ephuma kamva, ukuphucula ukusebenza kakuhle; Xa ushiya i-warehouse, i-algorithm iphinda iphakamise indawo yokugcina indawo efanelekileyo, kwaye ibala izinto ezahlukeneyo ezifana nomgama, isithintelo kwimisebenzi, kunye ne-inventory yokugqibela ukubonelela ngeyona ndawo yokugcina indawo; Inokuphinda ifezekise ukubonwa kwe-inventri kwaye ijonge ngokulula imeko yayo nayiphi na indawo yokugcina ngokusebenzisa ujongano lwegraphical, ngokuguquguquka okuqinileyo, ukuthembeka okuphezulu, i-scalability eyomeleleyo, kunye nokuguquguquka okuphezulu.

Ixesha lokuposa: Apr-26-2023