I-automated warehouse ene-dimensional three-dimensional yinxalenye ebalulekileyo yolungiselelo. Ineengenelo ezininzi ezinjengokugcina umhlaba, ukunciphisa amandla okusebenza, ukuphelisa iimpazamo, ukuphuculwa kwenqanaba le-automation ye-warehousing kunye nolawulo, ukuphucula umgangatho wolawulo kunye nabaqhubi, ukunciphisa ilahleko yokugcina kunye nothutho, ukunciphisa ngokufanelekileyo ukusilela kwenkunzi yokusebenza, kunye nokuphucula izixhobo zokusebenza. ukusebenza kakuhle, Kwangaxeshanye, i-warehouse ene-auto-dimensional three-dimensional edityaniswe nenqanaba lefektri yolawulo lwenkqubo yolwazi lwekhompyutha kwaye idityaniswe ngokusondeleyo nomgca wokuvelisa ikhonkco elibalulekileyo le-CIMS (iNkqubo yokuVelisa iComputer Integrated Manufacturing) kunye neFMS (inkqubo yokuvelisa eguquguqukayo). Ikwayinkqubo ezigcina ngokuzenzekelayo kwaye ikhuphe izinto zokusebenza ngaphandle kokungenelela ngokuthe ngqo ngesandla. Yimveliso yobugcisa obuphezulu bophuhliso loluntu lwemizi-mveliso yanamhlanje, kwaye kubalulekile ukuba amashishini aphucule imveliso Ukunciphisa iindleko kudlala indima ebalulekileyo.

Kwiminyaka yakutshanje, ngokuphuculwa okuqhubekayo kwemveliso kunye nolawulo lweshishini, ngakumbi nangakumbi amashishini ayaqonda ukuba uphuculo kunye nengqiqo yenkqubo yolungiselelo lolungiselelo kubaluleke kakhulu kuphuhliso lwamashishini. I-stacker yeyona nto ibalulekileyo yokuphakamisa kunye nezixhobo zokupakisha kwi-automated three-dimensional warehouse. Inokuthutha iimpahla ukusuka kwenye indawo ukuya kwenye ngokusebenza ngesandla, ukusebenza kwe-semi-automatic okanye ukusebenza okuzenzekelayo. Iyakwazi ukuhamba emva naphambili kwindlela ezenzekelayo-ntathu kwaye igcine iimpahla kwindawo yokungena kwindawo yempahla; Okanye ngokuchaseneyo, khupha iimpahla kwindawo yemithwalo kwaye uzithuthe ukuya kwindlela yokuwela, oko kukuthi, i-stacker ngumzila kaloliwe okanye i-trolley engenamkhondo exhotyiswe ngezixhobo zokunyusa. I-stacker ixhotyiswe ngemoto yokuqhuba i-stacker ukuze ihambe kwaye iphakamise i-pallet. Nje ukuba i-stacker ifumane indawo yomthwalo efunekayo, inokuzityhala okanye itsale ngokuzenzekelayo iinxalenye okanye iibhokisi zempahla ngaphakathi okanye ngaphandle kwe-rack. I-stacker ine-sensor yokufumanisa intshukumo ethe tye okanye ukuphakama kokuphakamisa ukuchonga indawo kunye nokuphakama kwendawo yempahla, Ngamanye amaxesha unokufunda negama leenxalenye ezikwisikhongozeli kunye nolunye ulwazi lwamacandelo afanelekileyo.

Ngophuhliso lwetekhnoloji yolawulo lwekhompyuter kunye ne-auto-dimensional warehouse, ukusetyenziswa kwe-stacker kubanzi ngakumbi, ukusebenza kobugcisa kubhetele kwaye kungcono, kwaye ukuphakama kuyanda. Ukuza kuthi ga ngoku, ukuphakama kwe-stacker kunokufikelela kwi-40m. Enyanisweni, ukuba ayikhawulelwanga ngokwakhiwa kwendawo yokugcina impahla kunye neendleko, ukuphakama kwe-stacker kunokungathintelwa. Isantya sokusebenza se-stacker sikwaphucula rhoqo. Okwangoku, isantya esisebenzayo se-stacker sifikelela kwi-200m / min (i-stacker enomthwalo omncinci ifikelele kwi-300m / min), isantya sokunyusa sifikelela kwi-120m / min, kunye nesantya se-telescopic yefoloko ukuya kwi-50m. / min.

Ukuqulunqwa kwe-stacker

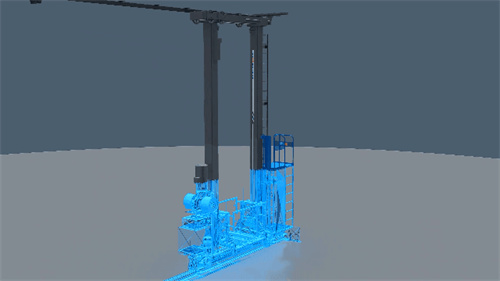

I-stacker yenziwe ngesakhelo (i-beam ephezulu, i-beam ephantsi kunye nekholomu), indlela yokuhamba ethe tye, indlela yokuphakamisa, iqonga lomthwalo, ifolokhwe kunye nenkqubo yokulawula umbane. Iinkcukacha zezi zilandelayo:

isakhelo

Isakhelo sisakhelo soxande esakhiwe ngumqadi ophezulu, iintsika zasekhohlo nasekunene kunye nomqadi osezantsi, osetyenziswa kakhulu ekuthwaleni. Ukuze kuququzelelwe ukufakwa kwamacandelo kunye nokunciphisa ubunzima be-stacker, imiqadi ephezulu kunye nesezantsi yenziwe ngentsimbi yentsimbi, kwaye iintsika zenziwe ngetsimbi yesikwere. I-crossbeam ephezulu ibonelelwa ngesithintelo sikaloliwe esibhakabhakeni kunye ne-buffer, kunye ne-crossbeam esezantsi ibonelelwa ngesithinteli sikaloliwe esisezantsi.

Indlela yokusebenza

Indlela yokuqhuba yindlela yokuqhuba yentshukumo ethe tyaba ye-stacker, ebandakanya ngokubanzi i-motor, ukudibanisa, i-brake, isinciphisi kunye nevili lokuhamba. Inokwahlulwa ibe luhlobo olubalekayo lomhlaba, uhlobo olusebenzayo oluphezulu kunye nodidi oluphakathi olusebenzayo ngokwezikhundla ezahlukeneyo zendlela yokusebenza. Xa uhlobo lokuhamba komhlaba lwamkelwa, amavili amane afuneka ukuba aqhube ecaleni kwe-monorail ebekwe phantsi. Umphezulu we-stacker ukhokelwa ngamacandelo amabini amavili anqamlekileyo kunye ne-I-beam egxininiswe kwi-beam ephezulu. Umqadi ongaphezulu udityaniswe neebholiti kunye neentsika, kwaye umqadi ongezantsi udityaniswe ngentsimbi yentsimbi kunye nentsimbi yentsimbi. Isixhobo sokuqhuba, ivili le-master-slave motor, ikhabhinethi yombane, njl.njl zonke zifakwe kuyo. Amacala amabini omqadi ongezantsi nawo axhotyiswe ngezithinteli ukuthintela isitaki ekuveliseni amandla amakhulu ongquzulwano ngenxa yokungalawuleki kuzo zombini iziphelo zetonela. Ukuba i-stacker idinga ukuthatha i-curve, uphuculo oluthile lunokwenziwa kumzila wesikhokelo.

Indlela yokuphakamisa

Isixhobo sokunyusa sisixhobo esenza ukuba iqonga lomthwalo lihambe ngokuthe nkqo. Ngokuqhelekileyo yenziwe ngemoto, ibhuleki, isinciphisi, igubu okanye ivili kunye namalungu aguqukayo. Amalungu asetyenziswa ngokuqhelekileyo aguquguqukayo aquka intambo yentsimbi yentsimbi kunye nekhonkco lokuphakamisa. Ukongeza kwisinciphisi segiya ngokubanzi, isinciphisi segiya yeentshulube kunye nesinciphisi seplanethi siyasetyenziswa ngenxa yesidingo somlinganiselo omkhulu wesantya. Uninzi lwezixhobo zokuhambisa ikhonkco lokuphakamisa zifakwe kwindawo ephezulu kwaye zihlala zixhotyiswe ngezinto ezichaseneyo zokunciphisa amandla okunyusa. Ukuze wenze umatshini wokunyusela ube compact, imotor ene brake ihlala isetyenziswa. Ikhonkco idibaniswe ngokusisigxina kunye ne-pallet ngokusebenzisa i-gear kwikholomu. Icandelo lenkxaso yokuphakamisa ngokuthe nkqo yikholomu. Ikholamu yibhokisi yesakhiwo kunye ne-primary anti distortion, kunye nomzila wesikhokelo ufakwe kumacala omabini ekholomu. Uluhlu lukwaxhotyiswe ngezitshixo zesimo somda ophezulu nasezantsi kunye namanye amacandelo.

Ifolokhwe

Ubukhulu becala yenziwe sisinciphisi semoto, isprocket, isixhobo sokudibanisa ikhonkco, ipleyiti yefolokhwe, umzila kaloliwe oshukumayo, umzila kaloliwe osisigxina, ukuthwala irola kunye nezinye izixhobo zokubeka indawo. Umatshini wefolokhwe yindlela yokulawula yokuba isitaki sifikelele kwiimpahla. Ifakwe kwi-pallet ye-stacker kwaye inokwandiswa ngokuthe tye kwaye ihlehliswe ukuze ithumele okanye ikhuphe iimpahla kumacala amabini egridi yempahla. Ngokubanzi, iifolokhwe zohlulwe zibe ziifolokhwe zefolokhwe enye, iifolokhwe ezimbini okanye iifolokhwe ezininzi ngokwenani leefolokhwe, kwaye iifolokhwe ezininzi zefolokhwe zisetyenziswa kakhulu ukupakisha iimpahla ezikhethekileyo. Iifolokhwe ubukhulu becala zinezigaba ezithathu zomgca wokwahluka kweefolokhwe zeteleskopu, ezenziwe ngefolokhwe engaphezulu, ifolokhwe ephakathi, ifolokhwe esezantsi kunye nenaliti ethwele umsebenzi okhokelayo, ukuze kuncitshiswe ububanzi bendlela kwaye iyenze ibenohambo olwaneleyo lweteleskopu. Ifolokhwe inokwahlulwa ibe ziindidi ezimbini ngokwesakhiwo sayo: imowudi ye-gear rack kunye ne-sprocket chain mode. Umgaqo we-telescoping wefolokhwe kukuba ifolokhwe esezantsi ifakwe kwi-pallet, ifolokhwe ephakathi iqhutywa yi-bar bar okanye ibha ye-sprocket ukuya ngasekhohlo okanye ngasekunene ukusuka kugxininiso lwefolokhwe esezantsi malunga nesiqingatha sobude bayo, kwaye ifolokhwe ephezulu idlulela ngasekhohlo okanye ngasekunene ukusuka kumbindi wefolokhwe ngobude obungaphezu kwesiqingatha sobude bayo. Ifolokhwe ephezulu iqhutywa ngamatyathanga amabini e-roller okanye iintambo zocingo. Esinye isiphelo sekhonkco okanye intambo yocingo igxininiswe kwifoloki ephantsi okanye i-pallet, kwaye enye isiphelo igxininiswe kwifoloki ephezulu.

Indlela yokuphakamisa kunye ne-pallet

Indlela yokuphakamisa ibandakanya ikakhulu i-motor yokunyusa (kubandakanya isinciphisi), i-drive sprocket, i-drive chain, i-sprocket ephindwe kabini, i-chain chain kunye ne-idler sprocket. Ikhonkco yokuphakamisa i-roller chain chain kunye ne-fector factor yokhuseleko enkulu kune-5. Yenza isakhiwo esivaliweyo kunye ne-idler sprocket kwi-pallet kunye nemigangatho ephezulu nangaphantsi. Xa i-motor ephakamisayo iqhuba ivili le-double chain chain ukujikeleza kwikhonkco lokuqhuba, ikhonkco lokunyusa liya kuhamba, ngaloo ndlela liqhuba iqonga lokunyusa (kubandakanya iifolokhwe kunye nempahla) ukunyuka nokuwa. I-motor yokuphakamisa ilawulwa yi-PLC yokuguqulwa rhoqo ukunqanda uxinzelelo olugqithiseleyo kwikhonkco lokuphakamisa ekuqaleni kokuphakamisa nokumisa. Iqonga lempahla lenziwe ikakhulu ngepleyiti yentsimbi ethe tyaba edityanisiweyo, esetyenziswa ikakhulu ukufaka iifolokhwe kunye nezinye izixhobo zokhuseleko. Ukuze kuqinisekiswe ukunyakaza okuzinzile kunye nokuhla kwe-pallet, amavili angama-4 esikhokelo kunye neevili ezi-2 eziphezulu kunye nekholomu zifakwe kwicala ngalinye le-pallet.

Izixhobo zombane kunye nolawulo

Ikakhulu ibandakanya ukuqhuba kombane, ukuhanjiswa komqondiso kunye nolawulo lwe-stacker. I-stacker ithatha umgca woqhagamshelwano otyibilikayo ukwenzela unikezelo lwamandla; Ekubeni unikezelo lwamandla ombane olulayini unxibelelwano lomthwali wonxibelelwano lulula ukuphazanyiswa ngamandla ombane, imowudi yonxibelelwano ye-infrared ene-anti-interference elungileyo yamkelwa ukutshintshiselana ngolwazi kunye nekhompyuter kunye nezinye izixhobo zokugcina impahla. Iimpawu zokusebenza ze-stacker kukuba kufuneka zibekwe ngokuchanekileyo kwaye zibhekiswe, ngaphandle koko ziya kuthatha iimpahla ezingalunganga, zonakalise iimpahla kunye namashalofu, kwaye zonakalisa i-stacker ngokwayo kwiimeko ezinzulu. Ulawulo lwendawo ye-stacker luthatha indlela yokuqaphela idilesi epheleleyo, kwaye i-laser range finder isetyenziselwa ukumisela indawo yangoku ye-stacker ngokulinganisa umgama ukusuka kwi-stacker ukuya kwindawo yesiseko kunye nokuthelekisa idatha egcinwe kwi-PLC kwangaphambili. Iindleko ziphezulu, kodwa ukuthembeka kuphezulu.

Isixhobo sokukhusela ukhuseleko

I-Stacker luhlobo lomatshini wokuphakamisa, ekufuneka ubaleke ngesantya esiphezulu kwiitonela eziphakamileyo nezimxinwa. Ukuze kuqinisekiswe ukhuseleko lwabasebenzi kunye nezixhobo, i-stacker kufuneka ixhotyiswe nge-hardware epheleleyo kunye nezixhobo zokukhusela ukhuseleko lwe-software, kwaye uchungechunge lweendlela zokudibanisa kunye nokukhusela ziya kuthathwa kulawulo lombane. Izixhobo ezingundoqo zokukhusela ukhuseleko zibandakanya ukukhuselwa komda we-terminal, ukukhuselwa kwe-interlock, ukulawulwa kokubona indawo efanelekileyo, ukukhuselwa kwentambo ye-cargo, ukukhusela umbane, njl.

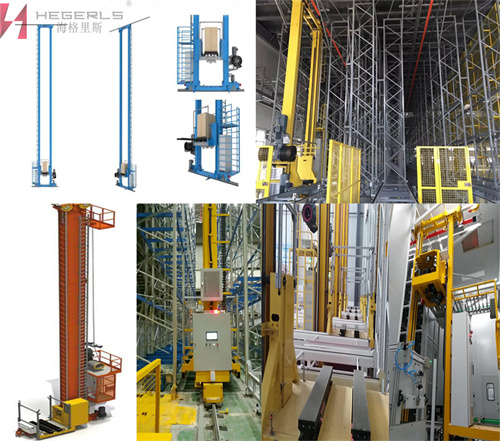

Ukumiselwa kwefom ye-stacker: kukho iindlela ezahlukeneyo ze-stacker, ezibandakanya i-monorail tunnel stacker, i-double rail tunnel stacker, i-rotary tunnel stacker, i-stacker eyodwa yekholomu, i-double column stacker, njl.

Ukuzimisela kwesantya se-stacker: ngokweemfuno zokuhamba kwe-warehouse, bala isantya esithe tye, ukuphakamisa isantya kunye nesantya sefoloko ye-stacker.

Ezinye iiparameters kunye noqwalaselo: imo yokubeka kunye nendlela yokunxibelelana ye-stacker ikhethwe ngokwemiqathango yesayithi yendawo yokugcina impahla kunye neemfuno zomsebenzisi. Ukucwangciswa kwe-stacker ingaba phezulu okanye ephantsi, kuxhomekeke kwimeko ethile.

Ukusetyenziswa kwesitaki esizenzekelayo esinemigangatho emithathu yendawo yokugcina impahla

*Qaphela ukugcina iphaneli yokusebenza icocekile kwaye icocekile, kwaye ucoce uthuli, i-oyile kunye nezinye ii-sundrides yonke imihla.

* Ekubeni isikrini sokuchukumisa kunye nezinye izinto zombane kwiphaneli yokusebenza zonakaliswa lula ngumswakama, nceda uzigcine zicocekile.

*Xa ucoca ipaneli yokusebenza, kuyacetyiswa ukuba usebenzise ilaphu elimanzi ukosula, kwaye unike ingqwalaselo ukuba ungasebenzisi izinto zokucoca eziyonakalisayo ezifana ne-oyile.

*Xa uhambisa i-AGV, i-drive kufuneka iphakanyiswe kuqala. Xa i-drive ihluleka ukuphakanyiswa ngenxa yezizathu ezithile, amandla e-AGV kufuneka acinywe. Akuvumelekanga ngokungqongqo ukuhambisa i-AGV xa i-drive ivuliwe kwaye i-drive ayiphakanyiswanga.

*Xa i-AGV ifuna ukumiswa ngexesha likaxakeka, iqhosha likaxakeka liya kusetyenziswa. Akuvumelekanga ukusebenzisa i-drag okanye ezinye iindlela zokuphazamiseka ukunyanzela i-AGV trolley ukuba ime.

*Akuvumelekanga ukubeka nantoni na kwiphaneli yokusebenza.

Ukugcinwa kwemihla ngemihla kwe-auto-dimensional warehouse stacker

*Coca ii-sundries okanye imicimbi yangaphandle kwisitaki kunye nendlela.

*Jonga ukuba kukho ukuvuza kwe-oyile kwindawo yokuqhuba, i-hoist kunye nefolokhwe.

*Jonga ukuma ngokuthe nkqo kwentambo.

*Khangela ukuguga kwesiporo esikhokelayo kunye nevili lesikhokelo kwikholamu.

*Coca amehlo okukhanya kwe-elektroniki / izinzwa ezifakwe kwisitaki.

* Uvavanyo lomsebenzi we-electronic optical eye / sensor efakwe kwi-stacker.

*Jonga ukuqhuba kunye nokusebenza kwevili (ukunxiba).

*Jonga izixhobo kwaye ujonge ukuba ivili lokuxhasa lonakele.

*Khangela ukuba akukho kuqhekeka kwindawo yokuwelda yoqhagamshelo lwekholamu kunye noqhagamshelo lwebholithi.

*Jonga indawo ethe tyaba yebhanti enamazinyo.

*Jonga ukushukuma kwesitaki.

*Jonga ngokubonakalayo umsebenzi wokupeyinta westacker.

Ngophuhliso lwemveliso yemizi-mveliso yanamhlanje, kwindawo yokugcina izinto ezintathu-ntathu, ukusetyenziswa kwe-stacker kuya kuba banzi ngakumbi, isetyenziswa ikakhulu kwimveliso yoomatshini, ukwenziwa kweemoto, ishishini leempahla, uloliwe, icuba, unyango kunye namanye amashishini, kuba la mashishini aya kuba ifaneleke ngakumbi ukusetyenziswa kwendawo yokugcina impahla ezenzekelayo yokugcina. IHagerls lishishini elibanzi elijolise kwisisombululo, uyilo, ukuvelisa kunye neenkonzo zofakelo zogcino olukrelekrele kunye nolungiselelo olukrelekrele oluxhasa izixhobo ezizenzekelayo. Inokubonelela abathengi nge-stacker yekholomu enye, i-double column stacker, i-stacker eguqukayo, i-double extension stacker kunye ne-bin stacker kunye nezinye iintlobo zezixhobo. Iyakwazi ukwenza ngokwezifiso iintlobo ezahlukeneyo zezixhobo ze-stacker ngokweemveliso ezahlukeneyo, kungakhathaliseki ukuba zingakanani kunye nobunzima.

Ixesha lokuposa: Aug-18-2022