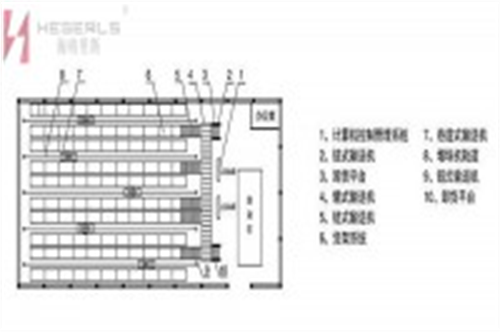

Isitora esikrelekrele esinemigangatho emithathu sisixhobo esibalulekileyo senkqubo yolungiselelo lwangoku. Isetyenziswa ngokubanzi kwiziko lolungiselelo. Indawo yokugcina impahla ekrelekrele enemigangatho emithathu ubukhulu becala yenziwe ziishelufu, iindlela zokupakisha iiCranes (izitaki), indawo yokugcina impahla (yokuphuma) amaqonga omsebenzi, iinkqubo zolawulo lokuthumela kunye neenkqubo zolawulo. Inkqubo yokusebenza kwendawo yokugcina izinto ezikrelekrele ezintathu ngokuqhelekileyo kukugcinwa, ukuphatha kwindawo yokugcina impahla, ukugcinwa kwempahla, ukuchola-chola kunye neempahla eziphuma kwindawo yokugcina iimpahla Umsebenzi wonke uqhutywa phantsi kolawulo lwenkqubo yekhompyutha. Inkqubo yekhompyuter iyinkqubo yolawulo kunye nolawulo lwamanqanaba amathathu. Ikhomputha ephezulu ixhunyiwe kwi-LAN, kwaye ikhompyutheni ephantsi ixhunywe kumlawuli we-PLC ukuhambisa idatha ngeendlela ezingenazintambo kunye neengcingo. Kwangaxeshanye, ukusekwa kwendawo yokugcina izinto ezikrelekrele kudlala indima ebalulekileyo ekuphuculeni ukusebenza kakuhle kolungiselelo lwamashishini. Kakade ke, ingxaki iyavela. Uninzi lwamashishini okanye abantu ngamanye amaxesha banokuzibuza ukuba isetyenziswa njani inkqubo yogcino olukrelekrele ngokuchanekileyo, kwaye yintoni umahluko phakathi kwayo kunye neendawo zokugcina iimpahla eziqhelekileyo? Ngawaphi amanqaku aphambili kwinkqubo nganye efanele ukuqwalaselwa? Landela amanyathelo omenzi weshelufu yokugcina i-hegerls, kwaye uphonononge iinkcukacha zenkqubo yokusebenza yendawo yokugcina impahla kunye!

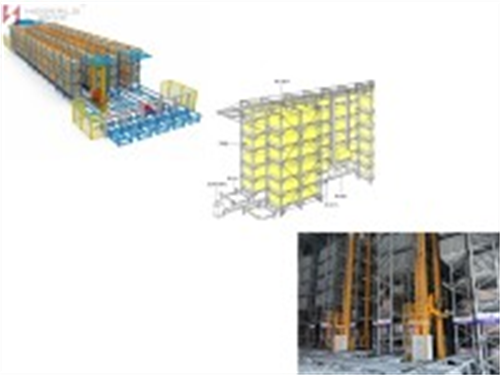

Ekuqaleni, sele sikhankanyile ukuba icandelo eliphambili le-warehouse ehlakaniphile liqulunqwe ngamashalofu, i-roadway type Stacking Cranes, i-warehouse entry (ukuphuma) i-workbench kunye nokuthutha ngokuzenzekelayo kwi-(exit) kunye nenkqubo yokulawula ukusebenza. Phakathi kwabo, ishelufu sisakhiwo okanye umzimba wesakhiwo wesakhiwo sentsimbi okanye isakhiwo sekhonkrithi esomeleziweyo, ishelufu yindawo yomthwalo oqhelekileyo, kwaye i-crane yokupakisha indlela ihamba ngendlela phakathi kweeshelfu ukugqiba umsebenzi wokugcina kunye nokuthatha. ; Ngokolawulo, inkqubo yeWCS isetyenziselwa ulawulo.

Nanga amanqaku aphambili kwinkqubo yokusebenza ye-warehouse ekrelekrele, ngolu hlobo lulandelayo:

Inkqubo yokugcina impahla: inkqubo yolawulo iya kusabela kwisicelo sogcino, kwaye emva koko ibhokisi yencoko yababini yogcino iya kuvela, ivumela umsebenzisi ukuba agcwalise igama kunye nobungakanani bempahla yokugcina;

Umbuzo womyalelo: emva koko inkqubo ibuza ubungakanani bomyalelo. Xa ubungakanani be-odolo bukhulu kunobungakanani be-inventri yempahla, inkqubo iya kunika i-alamu ngokukhawuleza. Ngaphandle koko, inkqubo yokusebenza iya kuthumela umsebenzi wokufumana irisithi Mo kwikhompyuter kwaye uyiprinte kwiphepha ledatha yerisithi;

Ukuskena kweWarehousing: ikhompyutha yokugcina ilawula inkqubo yebhakhowudi ukuskena iimpahla;

Ukuhlelwa kunye nokuthutha: emva kokuskena, ikhompyutha yokugcina iya kugweba kwakhona ukuba iimpahla eziskeniweyo ziyahambelana nomsebenzi. Ukuba kunjalo, ukulungiswa kwendawo yokugcina impahla kunye nokuthuthwa kuya kwenziwa. Ukuba akunjalo, isignali ye-alam iya kunikwa.

Ukuhlanganiswa kunye nokudibanisa: ngaphambi kokuba iimpahla ezincinci okanye iinxalenye zigcinwe, ukudibanisa kunye nokudibanisa kuyafuneka ngokubanzi ukuhlangabezana neemfuno zokugcina kunye nokusebenzisa ngokupheleleyo umthamo wendawo yokugcina. Iimpahla ezinkulu zinokugcinwa ngokuthe ngqo okanye zifakwe kwipallet ngokwemeko.

(I-Hercules hegerls umenzi weshelufu yokugcina i-shelf kufuneka kwakhona ichaze amanqaku aphambili eenkcukacha zokudibanisa kunye nokudibanisa: Ngokuqhelekileyo, ukudibanisa okusisigxina kunye nokudibanisa kuyamkelwa, oko kukuthi, iimpahla ezininzi okanye iinxalenye zohlobo olufanayo zifakwe kwi-pallet enye okanye kwisitya; kwezinye iimeko, ukwenzela ukwandisa ngakumbi umthamo wokugcinwa, imowudi yokudibanisa yamacandelo akhululekile angamkelwa, oko kukuthi, iindidi ezingahleliwe kunye nobungakanani buhlanganiswe kwizikhongozeli Kule ndlela, i-database, ulwazi olufana nekhowudi yebhetshi. ikhowudi yebhetshi, kunye nekhowudi yebhetshi yokufika yeempahla kunye neenxalenye zisetelwe ukudibanisa ubuninzi kunye nohlobo lweempahla kwipleyiti nganye kunye nendawo yazo yokugcina, ukwenzela ukuba kube lula ipleyiti ebuyela umva kunye nokudibanisa ngexesha lokunikezelwa.)

Igalelo lokuskena ibhakhowudi: Ngokuqhelekileyo, ibhakhowudi yeempahla iqulethe iindidi ezine zolwazi, ezizezi, inombolo yepallet, inombolo yenqaku, inombolo yebhetshi kunye nobungakanani. (Qaphela: ibarcode ifundwa sisikena, itolikwe sisidikhowuda, emva koko igqithiselwe kwikhompyuter ngojongano lwesiriyali sezibuko)

Inkqubo yomcimbi: xa inkqubo yokulawula iphendula kwisicelo somcimbi, ibhokisi yencoko yababini iya kuvela, ivumela umsebenzisi ukuba agcwalise igama kunye nobuninzi bempahla ekhutshiweyo;

Umbuzo wobungakanani be-inventri: xa inkqubo yokusebenza ibuza ubungakanani be-inventri, ukuba ubungakanani bokukhutshwa bukhulu kunobungakanani be-inventory yempahla, kuya kunikwa i-alam; ngenye indlela, inkqubo iya kuthumela uxwebhu lomsebenzi womba kwikhompyuter yomba kwaye iprinte uxwebhu lomba;

Umyalelo ophumayo: ikhompyutha ephumayo ithumela umyalelo ophumayo kumatshini we-stacker, othunyelwa kwi-shelf kwaye uhanjiswe kwi-platform ephumayo. Ikhompyuter ephumayo ilawula inkqubo yebhakhowudi ukuskena iimpahla;

Ukuhlela nokupakisha kwakhona: emva kokuskena, ikhompyutha yokugcina impahla iya kugweba ukuba iimpahla eziskeniweyo ziyahambelana na nomsebenzi. Ukuba aziguquguquki, ukulungiswa kwendawo yokugcina impahla kuya kwenziwa. Ukuba akunjalo, isignali ye-alam iya kunikwa.

Ukusebenza kwe-ASRS, inqaku eliphambili eliza kukhankanywa nguHercules hegerls umenzi weshelufu yokugcina kukusebenza kwe-stacker. Kukwakho namanqaku asibhozo ekufuneka abaqhubi bamashishini bawathathele ingqalelo, ngolu hlobo lulandelayo:

I-1) Imiyalelo yokuSebenza: ngaphambi kokuba usebenze i-stacker, umqhubi uya kufunda ngononophelo i-ASRS ye-ASRS ye-warehouse ye-three-dimensional warehouse, okanye umsebenzi unokuqhutywa kuphela emva kwesikhokelo esichanekileyo;

I-2) I-compressor yomoya: ngaphambi kokuba i-stacker (ikhompyutheni ephezulu) iqaliswe, i-compressor yomoya kufuneka ivulwe kuze kube yilapho uxinzelelo lugcinwe, kwaye ke i-stacker ingaqhutyelwa kwindawo yokugcina impahla, ngaphandle koko i-pallet kunye nomzimba womgca uya konakala ngefoloko;

3) Ukufikelela kwimpahla: ukufikelela ngesandla kwiimpahla ze-ASRS kwindawo yokugcina impahla enemigangatho emithathu kuya kwalelwa;

I-4) Izixhobo ze-induction: ngexesha lokusebenza kwangaphakathi nangaphandle, akuvumelekanga ukuba abaqeqeshwayo bagubungele izixhobo ze-induction zomshini wokuguqulela ongenayo, ophumayo okanye we-sorter jacking ngezandla zabo;

5) Uphawu lwesimo: enyanisweni, kukho amanqaku amathathu emo kwi-stacker, oko kukuthi, imo yezandla, i-semi-automatic status kunye ne-automatic status. Imo yezandla kunye ne-semi-automatic status zisetyenziswa kuphela ngokugunyaziswa okanye kulondolozo lwabasebenzi. Ukuba zisetyenziswe ngaphandle kwesigunyaziso, ziya kuthwala imiphumo; Ngexesha loqeqesho, kuqinisekiswa ukuba kukwimeko ezenzekelayo;

I-6) Iqhosha lokuyeka ngokukhawuleza: i-stacker ikwimeko ezenzekelayo, kwaye umsebenzi wokufikelela uqhutyelwa ngokuthe ngqo kwi-stacker. Kwimeko yonxunguphalo okanye ukungaphumeleli, ukucinezela iqhosha lokumisa likaxakeka kwi-interface yekhompyutheni ephezulu okanye iqhosha lokumisa umgca wonke kwikhabhinethi yokulawula umbane yomgca wokuhambisa nayo inefuthe lokuyeka ngokukhawuleza;

7) Ukhuseleko lwabasebenzi: ngexesha lemisebenzi yangaphakathi nangaphandle, akuvumelekanga ukuba abaqeqeshi basondele okanye bangene kwindawo yokugcina impahla enemigangatho emithathu kwaye balandele indlela yendlela, kwaye bangasondeli kakhulu malunga nendawo yokugcina izinto ezintathu, ugcine umgama ubuncinane we-0.5m. ;

I-8) Ukulungiswa kunye nokugcinwa: umgca wonke kufuneka ulungelelaniswe rhoqo kwiinyanga ezintandathu. Ewe, abasebenzi abangengabo abaqeqeshelwa umsebenzi abavumelekanga ukuba baqhaqhe kwaye batshintshe ngokuthanda kwabo.

Ewe kunjalo, sikwakhankanye ukuba yintoni umahluko phakathi kwe-ASRS kunye neendawo zokugcina iimpahla eziqhelekileyo?

Ngapha koko, akukho nzima ukubona ukuba umahluko omkhulu phakathi kwe-automated ye-automated ye-arehouse ye-ASRS kunye ne-warehouse eqhelekileyo ilele kwi-automation kunye nobukrelekrele bendawo yokugcina impahla ngaphakathi kunye ne-warehouse ngaphandle:

Isitora esiqhelekileyo sithetha ukuba iimpahla zibekwe phantsi okanye kwiishelufa eziqhelekileyo (zidla ngokuba ngaphantsi kweemitha ezisi-7) kwaye zifakwa ziphuma ngesandla kwindawo yokugcina impahla ngeforklift; I-automated-automated three-dimensional warehouse ASRS kukuba iimpahla zibekwe kwi-shelf ephezulu (ngokuqhelekileyo ngaphantsi kweemitha ezingama-22), kwaye phantsi kolawulo lwesofthiwe, izixhobo zokuphakamisa zingena ngokuzenzekelayo kwaye ziphume kwindawo yokugcina.

Ewe kunjalo, amanqaku aphambili okuba ithala leencwadi elinamacala amathathu e-ASRS lingcono kuneendawo zokugcina iimpahla eziqhelekileyo kule miba ilandelayo:

Uxhulumaniso olungenamthungo: lunokudityaniswa nenkqubo yokuvelisa ngokuzenzekelayo enyukayo kunye nenkqubo yokusasaza ezantsi ukuze kuphuculwe ububanzi kunye nobunzulu be-automation ye-enterprise supply chain.

Ulwazi: Itekhnoloji yokuchonga ulwazi kunye nesoftware exhasayo iqonda ulawulo lolwazi ngaphakathi kwendawo yokugcina impahla, enokuthi ibambe uguquko lwempahla ngexesha lokwenyani kwaye iqonde ukucwangciswa ngokukhawuleza.

Uqhagamshelo olungenamthungo koomatshini bokuphatha abahlukeneyo banokuqonda ukusebenza ngokungenamntu kwendawo yokugcina impahla, ukuze kuncitshiswe iindleko zabasebenzi kwaye kuthintelwe ingozi efihlakeleyo yokhuseleko lwabasebenzi kunye nomngcipheko womonakalo wempahla.

Isantya esiphezulu: isantya sokuhambisa somzila ngamnye sidlula i-50 Torr / h, ephezulu kakhulu kunelori ye-forklift, ukwenzela ukuba kuqinisekiswe isantya sokuhanjiswa kwendawo yokugcina impahla.

Okunzulu: ubude bokugcina bunokufikelela ngaphezu kwe-20m, indlela yendlela kunye nendawo yempahla iphantse ibe nobubanzi obufanayo, kwaye imowudi yogcino oluphezulu iphucula kakhulu izinga lokusetyenziswa komhlaba.

Ixesha lokuposa: Jun-09-2022