Ezona ndawo zisebenza ngokuzenzekela kwindawo yokugcina impahla enemigangatho emithathu yindawo yokufumana, indawo yokufumana, indawo yokuchola kunye nendawo yokuhambisa. Emva kokufumana inqaku lokuhanjiswa kunye neempahla kumthengisi, iziko lokugcina impahla liya kwamkela iimpahla ezisanda kufakwa ngeskena sebhakhowudi kwindawo yokufumana. Emva kokuqinisekisa ukuba inqaku lokuhambisa liyahambelana neempahla, iimpahla ziya kuqhutyelwa phambili. Inxalenye yempahla ibekwe ngokuthe ngqo kwindawo yokuhanjiswa, eyeyempahla yohlobo; Enye inxalenye yempahla yempahla yohlobo lokugcinwa, ekufuneka igcinwe, oko kukuthi, ingena kwindawo yokukhetha. Ukuchola kugqitywe ngokuzenzekelayo ngenkqubo yokuhlela kunye nokuhambisa ngokuzenzekelayo kunye nenkqubo yesikhokelo esizenzekelayo. Emva kokuhlelwa, iimpahla zingena kwi-automatically-dimensional warehouse. Xa iimpahla kufuneka zihanjiswe, ngokuhambelana nesiboniso kwinqaku lokuhambisa, iimpahla ziya kuthunyelwa kumgca wokulayisha ohambelanayo ngokuhlelwa ngokuzenzekelayo kunye nezixhobo zokuhambisa. Emva kokuba iimpahla zipakishwe, ziya kulayishwa kwaye zihanjiswe. Emva koko indlela yokuqwalasela ukusebenza kwendawo yokugcina i-automated three-dimensional? Ngoku masilandele i-hegerls warehouse ukuze sibone!

Ngokubanzi, izixhobo ezisetyenziswa ngokuqhelekileyo ezifunekayo ukufumana, ukugcinwa kunye nokuphuma ngaphandle koku kulandelayo:

Ukufumana ukusebenza

Impahla iya kuthuthelwa kwindawo echongiweyo ngololiwe okanye ngendlela ngezikhongozeli, kwaye izikhongozeli ziyakothulwa ngezixhobo zokusebenza zeekhonteyina (kubandakanywa ikhreyini yesikhongozeli, uhlobo lwamavili igantry crane, uhlobo lukaloliwe igantry crane, njl. njl.). Ngokubanzi, iimpahla ezikwisikhongozeli zifakwa kwipalethi kuqala, kwaye ke iimpahla zikhutshwa kunye nephalethi ngeforklift yokuhlola indawo yokugcina impahla.

Umsebenzi wogcino

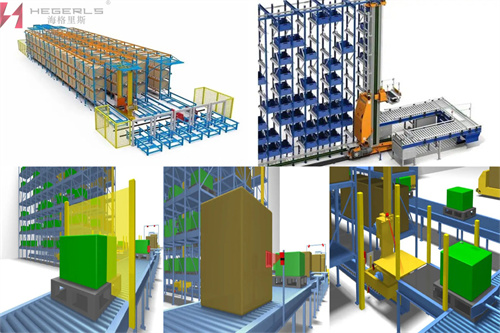

Emva kokuba iimpahla zihlolwe ekungeneni kwendawo yokugcina impahla, ziya kufakwa kwi-pallet ekhethiweyo ngokwemiyalelo ekhutshwe yinkqubo yokugcina ikhompyutha. Ngokuqhelekileyo, i-forklift, i-pallet carrier, i-conveyor kunye ne-automatic guided carrier zisetyenziswa kunye ukubeka iimpahla kwi-pallet. I-conveyor ingaba yibhanti yokuhambisa okanye i-roller conveyor. Ngokubanzi, i-conveyor kunye ne-AGV zilawulwa yikhompyutheni.

Emva kokuba iimpahla zibekwe kwipalethi, i-laneway stacker iya kubeka iimpahla kwindawo ekhethiweyo ngokwemiyalelo yesenzo, kwaye emva koko isitaki somzila siya kuhamba ngobude ecaleni kwendlela. Ngexesha elifanayo, i-pallet iya kuphakama kunye nekholomu ye-stacker. Ngexesha lokusebenza kunye nokuphakanyiswa kwe-stacker ye-laneway, ulwazi lwedilesi luya kuhanjiswa ngokuqhubekayo kwikhompyutheni. Ngelo xesha, ikhomputha iya kuthumela imiyalelo eyahlukeneyo kwi-stacker ye-laneway ukulawula inkqubo yokusebenza ye-laneway stacker, Ekugqibeleni, beka iimpahla kwindawo echongiweyo kwi-shelf.

Apha, i-hegerls iphinda ikhumbuze amashishini amakhulu ukuba iishelufu eziphezulu kunye ne-stackers kwi-warehouse ene-dimensional-dimensional ilula ukuqonda iimveliso ezisemgangathweni; Nangona kunjalo, inkqubo yokuthunyelwa kwempahla engenayo nephumayo iya kucwangciswa ngokukodwa kwaye iyilwe ngokuhambelana nokwakheka kwendawo yokugcina impahla, umxholo wemisebenzi engenayo nephumayo, inani lezikhululo ezingenayo neziphumayo, kunye neemfuno zophambuko nokudibanisa. Ukucwangciswa kunye noyilo lwenkqubo yokuthutha engenayo nephumayo ngundoqo ekusetyenzisweni kwe-automated warehouse ene-three-dimensional. Ukucwangciswa kunye noyilo lwenkqubo yokuthutha engenayo kunye nephumayo ihambelana ngokusondeleyo kwimilinganiselo yonke kunye ne-substructure ye-pallet, iindlela zokulayisha kunye nokukhupha, iindlela zokulawula ngokuzenzekelayo kunye neendlela zokufumanisa izixhobo ezifanelekileyo ze-logistics.

Ukusebenza kwangaphandle

Ukuhanjiswa kwempahla kunye nokusebenza kwendawo yokugcina impahla kulawulwa yinkqubo yolawulo efanayo, kwaye inkqubo yokusebenza ichasene.

Okwangoku, kukho iindidi zoomatshini abakhethekileyo bokusebenza, njengabahambisi abangenayo nabaphumayo, abayinxalenye ebalulekileyo yeendawo zokugcina iimpahla ezinkulu nezinzima. Badityaniswe ne-stackers kunye nabanye oomatshini ukuphumeza ukuthuthwa kwempahla ngesantya esiphezulu. Nangona iinkqubo zokuthutha ezingenayo neziphumayo zomsebenzisi ngamnye zahlukile, zisaqulunqwe ziintlobo ezahlukeneyo zokuhambisa (i-chain conveyor, i-roller conveyor, i-chain roller table composite conveyor, i-chain roller table composite conveyor ene-roller table ehambisa umsebenzi) kunye neemodyuli zabo ezisisiseko. .

Ixesha lokuposa: Aug-10-2022