Kuluntu lwanamhlanje, umhlaba uya usiba nexabiso kwaye unqongophele. Indlela yokubeka iimpahla ezininzi kangangoko kunokwenzeka kwindawo elinganiselweyo yingxaki eqwalaselwa ngamashishini amaninzi. Ngophuhliso lwamaxesha, ukusetyenziswa kwentsimbi kuye kwaxhaphaka kakhulu. Isakhiwo ikakhulu esenziwe ngentsimbi yenye yezona ntlobo zibalulekileyo zezakhiwo zokwakha. Ngokuqinisekileyo, ngophuhliso loqoqosho kunye nesidingo esiphuthumayo samashishini amakhulu, iishelufu zeplatifomu zensimbi ziye zasetyenziswa ngobuninzi. Emva koko, kuya kubakho iingxaki, njengokuba indawo yokugcina ishishini isebenzisa iishelufu zeplatifomu yensimbi okanye ezinye iishelufu zokugcina? Nguwuphi umahluko phakathi kwale shelufu yeqonga lentsimbi kunye nezinye iishelufu? Luluphi uhlobo lokugcinwa olufunekayo ekusebenziseni imihla ngemihla yeeshelufu zeplatifomu yensimbi? Ngoku, vumela umenzi weshelufu yokugcina iHergels akuxelele iiyantlukwano kunye nokugcinwa kokhuseleko phakathi kweeshelufu zeplatifomu yentsimbi kunye nezinye iishelufu!

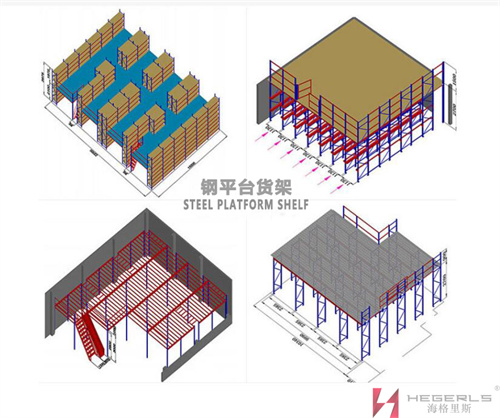

Amashalofu eplatifti yensimbi, eyaziwa ngokuba ngamaqonga okusebenza, zakhiwo zobunjineli ezenziwe ngentsimbi, ngokuqhelekileyo ziqulunqwe ngamaplanga, iikholomu, iiplate kunye nezinye izinto ezenziwe ngentsimbi yecandelo kunye namacwecwe ensimbi; Zonke iindawo zixhunywe kunye ne-welds, izikrufu okanye iirivets. Iishelufu zeqonga lensimbi zanamhlanje zinezakhiwo ezahlukeneyo kunye nemisebenzi. Isici sayo sesakhiwo sihlanganiswe ngokupheleleyo kunye noyilo oluguquguqukayo, olusetyenziswa ngokubanzi kwisitoreji samanje. Iqonga lesakhiwo sensimbi ngokuqhelekileyo lakha iqonga elinemigangatho emibini okanye emithathu ehlanganiswe ngokupheleleyo kwi-workshop ekhoyo (indawo yokugcina impahla), ukutshintsha indawo yokusetyenziswa ukusuka kumgangatho omnye ukuya kwimigangatho emibini okanye emithathu, ukwenzela ukuba kusetyenziswe ngokupheleleyo indawo. Impahla ihanjiswa kumgangatho wesibini kunye nomgangatho wesithathu nge-forklift okanye i-elevator yempahla yeqonga lokunyusa, kwaye emva koko ihanjiswe kwindawo echongiweyo ngetroli okanye i-hydraulic pallet iloli. Xa kuthelekiswa neqonga lekhonkrithi elomeleziweyo, eli qonga lineenzuzo zokwakha ngokukhawuleza, ixabiso eliphakathi, ukufakwa lula kunye nokuchithwa, kulula ukuyisebenzisa, kunye neveli kunye nesakhiwo esihle. Umgama phakathi kweekholomu zeli qonga ngokuqhelekileyo ngaphakathi kwe-4-6m, ukuphakama komgangatho wokuqala malunga ne-3M, kunye nokuphakama komgangatho wesibini nowesithathu malunga ne-2.5m. Iintsika zihlala zenziwe ngeetyhubhu ezisikwere okanye iityhubhu ezijikelezayo, eyona miqadi kunye neyokuncedisayo idla ngokwenziwa ngentsimbi emile okwe-H, i-slab yomgangatho idla ngokwenziwa nge-slab yomgangatho obandayo oqengqelekayo, ipateni eqinileyo, iplanga yomgangatho oqinileyo, igrayiti yentsimbi, kunye nentsimbi. umthwalo womgangatho udla ngokuba ngaphantsi kwe-1000kg nge-square meter nganye. Olu hlobo lweqonga lunokudibanisa indawo yokugcina impahla kunye nolawulo kumgama okufutshane. Umgangatho ophezulu okanye osezantsi unokusetyenziswa njengeofisi yokugcina impahla. Ezo nkqubo zisetyenziswa kakhulu kulungiselelo lweqela lesithathu, ukwenziwa koomatshini kunye namanye amashishini.

Ngolu hlobo lwenkqubo yeshelufu, kufuneka siqale siqhube i-containerization kunye ne-unitization, oko kukuthi, ukupakisha iimpahla kunye nobunzima bazo kunye nezinye iimpawu, ukucacisa uhlobo, ukucaciswa kunye nobukhulu be-pallet, kunye nobunzima obunye kunye nokuphakama kokupakisha ( Ubunzima obunye buhlala bungaphakathi kwe-2000kg), kwaye emva koko umisele ubunzulu besithuba kunye nesithuba somaleko weshelufu yeyunithi ngokobude obusebenzayo kunye nefolokhwe yomgca ongezantsi wophahla lwendawo yokugcina impahla. Ubude beefolokhwe zelori bumisela ubude beeshelufu. Ubude beeshelufu zeyunithi ngokuqhelekileyo bungaphantsi kwe-4m, ubunzulu bungaphantsi kwe-5m, ukuphakama kweeshelufu kwiindawo zokugcina iimpahla eziphakamileyo ngokuqhelekileyo zingaphantsi kwe-12M, kwaye ukuphakama kweeshelufa kwiindawo zokugcina iimpahla eziphakamileyo zingaphantsi kwe-30m (ezinjalo. iindawo zokugcina iimpahla ngokusisiseko ziindawo zokugcina iimpahla ezizenzekelayo, kwaye ubude beshelufu bubonke buqulunqwe ziikholamu ezili-12). Olu hlobo lwenkqubo yeshelufu lunosetyenziso lwendawo ephezulu, ukufikelela okuguquguqukayo, ulawulo olufanelekileyo lwekhompyuter okanye ulawulo, kwaye lunokuhlangabezana neemfuno zenkqubo yolungiselelo lwangoku.

Iishelufu zeqonga lentsimbi - iinkcukacha ziqinisekisa ukusetyenziswa okukhuselekileyo kweeshelufu

Ikholomu - khetha umbhobho ojikelezayo okanye umbhobho wesikwele onamandla okuthwala;

Imiqadi ephambili kunye neyesibini - khetha intsimbi esetyenziswa ngokuqhelekileyo i-H kwizakhiwo zetsimbi ngokweemfuno zokuthwala;

Umgangatho - umgangatho uneplate yensimbi ye-checkered, ibhodi yokhuni, i-plate yensimbi engenanto okanye i-steel grating floor ukukhetha kuyo, enokuthi ihlangabezane neemfuno ezahlukeneyo zokuthintela umlilo, umoya, ukukhanya kunye nokunye.

Iqonga lentsimbi yentsimbi - izixhobo ezincedisayo

Iileli, izilayidi - izitebhisi zisetyenziselwa ukuba abaqhubi bahambe ukuya kumgangatho wesibini nowesithathu. Isilayidi sisetyenziselwa ukuslayida iimpahla ukusuka phezulu ukuya ezantsi, egcina kakhulu iindleko zabasebenzi;

Iqonga lokuphakamisa - elisetyenziselwa ukuthutha phezulu nangaphantsi kwempahla phakathi kwemigangatho, eyongayo kunye nokusebenzayo, enomthamo omkhulu wokuthwala kunye nokuphakanyiswa okuzinzileyo;

I-Guardrail - i-guardrail ixhotyiswe kwindawo engenaludonga ukuqinisekisa ukuba akuyi kubakho ngozi zokhuseleko kubasebenzi kunye nempahla;

I-Plywood yokhuni - umgangatho uhlanjululwe ngeeplanga zokhuni, ezinqanda uxinzelelo, zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala zihlala khona.

I-steel gusset plate - umphezulu we-steel gusset plate material ugqamile, unomthwalo omhle, ukuchasana kwempembelelo kunye nokusebenza kokhuseleko;

Ipleyiti yentsimbi ekhuselweyo - ipleyiti ekhethekileyo ye-galvanized checkered steel gusset ye-attic, enganyangekiyo ekuqaleni, ayigugi, isiqinisekiso sokutyibilika kunye nesiqinisekiso sokhuseleko.

Impembelelo yobukhulu beshelufu yeqonga lentsimbi ekuthwaleni umthwalo

Imiqadi ephambili kunye neyesibini efunekayo yokwenziwa kweplatifomu yesakhiwo sensimbi kufuneka ibe yomelele, kwaye ukuxhaswa kwesakhiwo seqonga lonke kuxhomekeke kwimiqadi ephambili kunye neyesibini, ngoko kufuneka ibe yomelele kwaye yomelele ekuthwaleni umthamo. Kukho izinto ezininzi ezichaphazela ukuthwala umthwalo weqonga lesakhiwo sensimbi. Ichatshazelwa ikakhulu kukubekwa kwamalungu, njengale: isithuba sokubeka isithuba kunye nobukhulu becandelo, iimeko zenkonzo, oko kukuthi ukuba ukusetyenziswa kuyafikeleleka, ngaphakathi nangaphandle, njl. njl., umthwalo wengingqi, okt ukubonelela indawo yokusetyenziswa, echaphazela umthwalo ophilayo, i-seismic. umthwalo, umthwalo womoya, njl.

Yintoni umahluko phakathi kweeshelufa zeqonga lentsimbi kunye nezinye iishelufu?

I-1) Isakhiwo esidibeneyo siphucula ukusebenza kakuhle

Ukugcinwa kunye neofisi inokuqulunqwa njengesakhiwo esidibeneyo, ukwenzela ukuba kuphuculwe ukusebenza kakuhle. Iyakwazi ukuxhotyiswa ngezixhobo zokukhanyisa, izixhobo zokulwa nomlilo, izitebhisi zokuhamba, izilayidi zempahla, ii-elevators kunye nezinye izixhobo.

I-2) Isakhiwo esihlanganiswe ngokupheleleyo sineendleko eziphantsi kunye nokwakhiwa ngokukhawuleza

Ishelufu ye-attic iqwalasela ngokupheleleyo i-logistics ye-humanized, kwaye inesakhiwo esidityanisiweyo ngokupheleleyo, esilungele ukufakela kunye nokuchithwa, kwaye sinokuyilwa ngokuguquguqukayo ngokweyona ndawo kunye neemfuno zempahla.

3) Umthwalo ophezulu kunye nobukhulu obukhulu

Isakhiwo esiphambili senziwe nge-I-steel kwaye igxininiswe nge-screws, kunye nokuqina okuqinileyo. Ubude boyilo lweqonga lensimbi likhulu, elinokuthi libeke iziqwenga ezinkulu ezifana neepaliti, kwaye zingasetyenziselwa ukusetyenziswa kweofisi, kunye neeshelufu zamahhala. Iguquguquka kakhulu kwaye iyasebenza, kwaye isetyenziswa ngokubanzi kuzo zonke iintlobo zeendawo zokugcina iimpahla.

4) Ukuqonda ulawulo lwendawo yokugcina impahla kunye nokugcina izikhundla

Ngelixa izikhundla zonga, iphucula izinga lokuguqulwa kwemathiriyeli, iququzelela uluhlu lwemathiriyeli, iphinda kabini iindleko zabasebenzi bolawulo lwesitora, kwaye iphucula ngokubanzi inqanaba lolawulo lolawulo lwempahla yeshishini.

Ukugcinwa kokhuseleko kwi-shelf yesikhulumi sensimbi

1) Iqonga lensimbi liya kunikwa iplati yomthwalo womthwalo.

2) Indawo yokubeka kunye nenqanaba eliphezulu lentsimbi yentsimbi kufuneka ibekwe kwisakhiwo, kwaye ayiyi kusekwa kwi-scaffold kunye nezinye izakhiwo zokwakha, kwaye inkqubo yokuxhasa ayiyi kudibaniswa ne-scaffold.

3) I-concrete beam kunye ne-slab kwindawo yokubeka i-shelf yeqonga lensimbi iya kufakwa kwaye idibaniswe kunye neebholiti zeqonga.

4) I-angle ethe tyaba ibandakanya i-angle phakathi kwentambo yentsimbi yentsimbi kunye neqonga kufuneka libe yi-45 ℃ ukuya kuma-60 ℃.

I-5) Amandla obunzima bemiqadi kunye neentsika zemibhobho yokubambisana kwinqanaba eliphezulu lentsimbi iya kujongwa ukuze kuqinisekiswe ukhuseleko lwesakhiwo kunye neqonga.

6) Iringi ye-snap iya kusetyenziselwa iqonga lensimbi, kwaye ikhonkco ayiyi kubamba ngokuthe ngqo ikhonkco.

7) Xa iplatifomu yensimbi ifakwe, intambo yocingo yensimbi kufuneka ixhonywe ngokuqinileyo ngeekhonkco ezikhethekileyo. Xa ezinye iindlela zamkelwe, kufuneka kungabi ngaphantsi kwe-3 buckles. Intambo yentsimbi yentsimbi ejikeleze ikona ye-acute yesakhiwo kufuneka ifakwe kwii-cushions ezithambileyo, kwaye ukuvulwa kwangaphandle kweqonga lensimbi kufuneka kube phezulu kancinci kunecala langaphakathi.

I-8) Izandla eziqingqiweyo kufuneka zibekwe kwicala lasekhohlo nasekunene kwiqonga lensimbi, kwaye amanetha okhuseleko axineneyo kufuneka axhonywe.

Umvelisi weshelufu yokugcina iHagerls

I-Hagerls ngumenzi obandakanyeka kwimveliso yeeshelufu zokugcina ezixineneyo, izixhobo zokugcina ezikrelekrele kunye neeshelufu zokugcina ezinzima. Ineminyaka engaphezu kwe-20 yamava kwimveliso yokugcina ngokwezifiso, ukucwangciswa kokugcinwa okuhlakaniphile okuhlukeneyo, kunye nokubonelela ngeenkonzo ezidibeneyo kwiishelufu. Iimveliso zethu eziphambili zezi: ishelufu yokuShutha, ishelufu yebhamu, ishelufu yendlela ezine, ishelufu ye-attic, ishelufu yeqonga yentsimbi, idrayivu kwishelufu, ishelufu yesakhiwo sentsimbi, ishelufu etyibilikayo, ishelufu yomxhuzulane, ishelufu, ishelufu yendlela emxinwa, ishelufu yobunzulu obuphindwe kabini, njl. Ukuba unomdla kwiishelufu zethu zokugcina kunye nezixhobo zokugcina, nceda ukhululeke ukubonisana nenkampani yethu, Sijonge phambili ukubonelela ngeenkonzo zokucwangcisa ukugcinwa kubathengi abavela kwihlabathi lonke!

Ixesha lokuposa: Jul-27-2022