Ngophuhliso olukhawulezayo lweshishini lolungiselelo, i-pallet-way-4-way shuttle rack i-warehouse ene-dimensional-dimensional warehouse iye yaphuhliswa yaba yenye yeendlela eziphambili zokugcina iimpahla ngenxa yeenzuzo zayo zokusebenza ngokufanelekileyo kunye nokugcinwa okunzulu, iindleko zokusebenza kunye nolawulo olucwangcisiweyo kunye nolukrelekrele. inkqubo yokujikeleza nokugcinwa kwayo. Kwiminyaka yakutshanje, i-hegerls intelligent pallet four-way shuttle shelf iphumelele inkoliseko yamashishini amaninzi, kwaye iqokelele amava athile esicelo kumandla amatsha, imveliso ekrelekrele, unyango, izihlangu kunye namanye amashishini. Ke, abathengi beshishini abangekayisebenzisi ishelufu yendlela ezine pallet shuttle yehaigris kufuneka babuze ukuba i-haigris inokuqinisekisa njani ukuba inkqubo yeshelufu yendlela emine yeepalethi inokusebenza ngokufanelekileyo? Ngoku, ukusuka kwiimpawu kunye noyilo olusebenzayo lwe-pallet ezine-shelf shuttle shelf, i-haigris ihlalutya ngokukodwa kwaye iphendule ukuba i-haigris inokuqinisekisa njani ukusebenza kakuhle kwe-pallet yendlela ye-shelf ye-shuttle system?

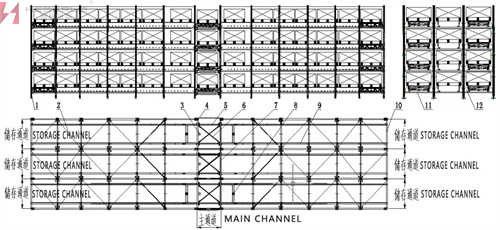

I-pallet ye-four-way vehicle rack yi-pallet four-way shuttle rack, eyona nto iqulunqwe ziziqwenga ezime nkqo, imiqadi exhasayo, iiplanga ezisezantsi, iireyili zabazali, iirodi zokutsala, izixhaso eziphelayo, iireyile ezibuyela umva, njl.

1 – ikholamu isiqwenga sesi-2 – intonga yeqhina ethe tyaba yomzila kaloliwe wesi-3 – inkxaso yokumisa ifoto yombane 4 – isiporo esikhuselayo ekupheleni kwesitishi esikhulu sesi-5 – isiporo esibuya umva 6 – intonga enqamlezileyo yomzila kaloliwe obuyela umva 7 – umzila omkhulu (ithambeka) 8 – ukutshaja imfumba ye-9 - i-sub track (itonela) 10 - isiporo sokukhusela ekupheleni kwe-sub channel 11 - umqadi oxhasayo we-12 - inkxaso yokuphela

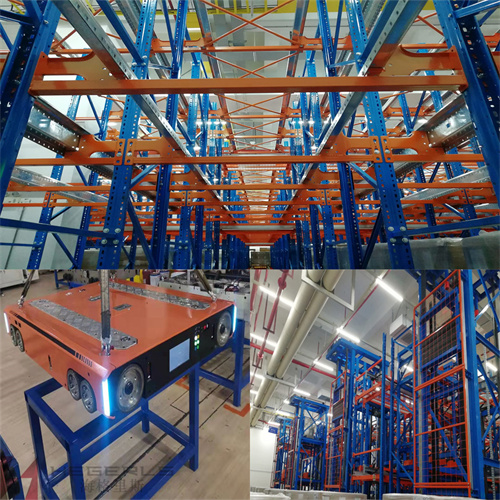

I-pallet ezine-way shuttle automatic storage dense system sisisombululo esitsha sokugcina esizenzekelayo. Iyakwazi ukuqonda iindidi zemisebenzi yokugcina ngokuzenzekelayo ngokusebenzisa uqwalaselo oluguquguqukayo. Iyakwazi ukuqwalaselwa njengendawo eshinyeneyo yokugcina isivalo, i-laneway ye-automatic-dimensional warehouse rack, kunye neenkqubo ezahlukeneyo zothutho. Inkqubo ilungele ukuguqulwa okuzenzekelayo kwendawo yokugcina impahla ephantsi, i-warehouse eneentsika ezininzi kunye ne-warehouse enemilo engaqhelekanga. Ngokweemfuno ezichanekileyo zokusebenza, inani lezixhobo linokuthi liqwalaselwe ngokufanelekileyo ngokweemfuno, ukuze kusonjululwe iziphene zeendleko eziphezulu zogcino kunye nolwakhiwo oluntsonkothileyo lomatshini lwendawo yokugcina impahla enemigangatho emithathu ezenzekelayo.

Q: njengomboneleli wezixhobo ezikrelekrele, zeziphi iimpawu zohlobo lwe-pallet ezine-way-intelligent shuttle rack eyenzelwe kwaye yaveliswa yi-hegerls?

I-1) I-pallet yeendlela ezine ze-shuttle inesakhiwo esincinci: ukuphakama okuncinci kunye nobukhulu, ukugcina indawo yokugcina indawo; Ayinakuhamba kuphela kumacala amane kwindlela yokubeka exhasayo, kodwa iphinde isebenzise i-elevator ethe nkqo ukuqonda umsebenzi wokutshintsha umaleko, okwandisa ngakumbi ukuguquguquka kunye nokuqina koyilo lwe-rack rack kunye nokusebenza kwigaraji yeendlela ezine.

2) Indlela emine yokuhamba: inokuhamba ngeendlela ezithe nkqo okanye ezithe tye kwi-rack ye-three-dimensional rack crossing track ukuze iqonde ukuthuthwa kwe-stop point-to-point, kwaye inokufikelela kuyo nayiphi na indawo kwindawo yokugcina impahla;

I-3) Ukutshintshwa kwe-Intelligent layer: ngoncedo lwe-higris elevator, imoto ye-shuttle inokuqonda indlela yokusebenza esebenzayo yokutshintsha okuzenzekelayo kunye nokuchanekileyo; Ukuqonda ukuhamba kwe-three-dimensional kwisithuba kwaye ulawule ngokuchanekileyo indawo yokugcina impahla kunye nokuphuma kwendawo nganye yempahla kwindawo yeshelufu yensimbi;

4) Ulawulo oluhlakaniphile: luneendlela zokusebenza ezizenzekelayo kunye ne-semi-automatic. Iphucula kakhulu ukusebenza kakuhle kweempahla ezingenayo kunye nokusetyenziswa kwendawo yokugcina impahla. I-docking ye-WMS kunye ne-WCs ye-software ye-software kunye ne-ERP / SAP / MES yezoshishino kunye nezinye isofthiwe yenkqubo yokulawula inokugcina indlela yokuqala yokugcina impahla, kunye nokuphelisa ukuphazamiseka okanye ukusebenza kakuhle kwezinto zabantu;

5) Izinga eliphezulu lokusetyenziswa kwendawo yokugcina impahla: ukuxinana kwendawo yokugcina impahla yemveli iphantsi, nto leyo ekhokelela kumlinganiselo ophantsi wokusetyenziswa kwendawo yokugcina impahla kunye nezinga eliphantsi lokusetyenziswa komthamo wesitora; I-pallet ye-shuttle ye-four-way-shuttle car ihamba ngeendlela ezine kwindlela ephambili kwi-rack, kwaye inokugqiba umsebenzi ngokuzimeleyo ngaphandle kokulungelelaniswa kwe-forklift kunye nezinye izixhobo. Ekubeni umthamo wengoma ephambili ye-rack incinci kunomthamo wetshaneli ye-forklift, i-pallet yeendlela ezine i-shuttle ye-othomathikhi yenkqubo yokugcina i-shuttle inokuphucula ngakumbi izinga lokusetyenziswa kwendawo yokugcina xa kuthelekiswa nenkqubo ye-rack ye-shuttle yemoto, ethi inganyuka ngokubanzi nge-20% ~ 30%, nto leyo ephindwe nge-2 ~ 5 indawo yokugcina impahla eqhelekileyo;

I-6) Ulawulo olunamandla kwindawo yomthwalo: indawo yokugcina impahla yemveli yindawo kuphela apho kugcinwa khona iimpahla, kwaye ukugcinwa kwempahla ngumsebenzi wayo kuphela. Luhlobo "lwendawo yokugcina engatshintshiyo". I-pallet ye-4-way shuttle car sisixhobo sokuphatha izinto ezizenzekelayo ezizenzekelayo, ezinokuthi zenze iimpahla zigcinwe ngokuzenzekelayo kwindawo yokugcina impahla ngokweemfuno, kodwa zidibanise ngokubonakalayo kunye namakhonkco emveliso ngaphandle kwendawo yokugcina impahla, ukuze zenze i-advanced. inkqubo yolungiselelo kunye nokuphucula inqanaba lolawulo lweshishini;

I-7) Imodeli ye-warehouse ezenzekelayo engasebenziyo: inciphisa kakhulu umsebenzi wabasebenzi bendawo yokugcina impahla kwaye ibonelela ngamathuba omsebenzi ongenamntu kwindawo yokugcina impahla. Indawo yokugcina impahla enemigangatho emithathu yokuhanjiswa kwemveliso iqhagamshelwe ngokuthe ngqo kwipalethi yeendlela ezine zokujikeleza umatshini, ukuphakamisa okuthe nkqo kweempahla kunye nokuhambisa okuzenzekelayo. Abasebenzi be-warehouse kufuneka bajonge kuphela ukusebenza kwenkqubo ngamaxesha onke ukuze baqonde ukufikelela kwi-automation, kwaye akukho mfuneko yokungena kwindawo yokugcina impahla ukuze isebenze. Ilungele ngokukhethekileyo ukugcinwa kweendawo zokugcina iimpahla ezingafanelanga ukuvalelwa ixesha elide kwabasebenzi, Liyisikhokelo sophuhliso logcino olunoxinano oluphezulu kunye nogcino oluzenzekelayo kwixesha elizayo.

I-8) Indawo yokushisa: i-pallet ezine-shelf shuttle shelf eyenziwa yi-hegerls inokuphinda ifezekise iindlela ezimbini zokusingqongileyo: ukusebenza okuqhelekileyo phantsi kokugcinwa kobushushu obuphezulu kunye nokugcinwa kweqondo lokushisa eliphantsi.

I-9) Ukusebenza koKhuseleko: sebenzisa i-hardware yamanqanaba amaninzi kunye ne-software edibeneyo yokubeka iliso, usethe umgama okhuselekileyo wokusebenza kunye nemigaqo yokugweba, kunye nokuqinisekisa ukusebenza okukhuselekileyo kwesithuthi sonke ngokusebenzisa i-blocker limit limit blocker okanye i-anti-over-turning mechanism.

Umbuzo: ngaphezu kwezi mpawu zingentla, zeziphi iimpawu zeshelufu ye-pallet ye-pallet ye-four-way kwi-design ethile yokusebenza ukuqinisekisa ukusebenza kakuhle kwenkqubo yeshelufu ye-pallet-way-pallet shuttle?

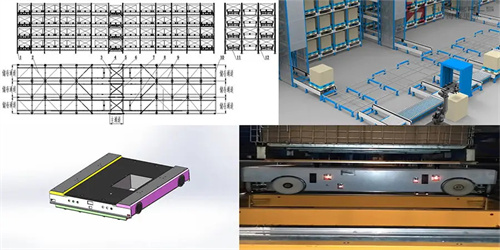

I-rack yelori ye-shuttle yendlela ezine ye-haigris pallet ine-motor eyodwa yokuqala kunye nemodi yokunciphisa, enokuqonda ukusebenza okuzinzileyo phantsi kokukhawuleza okuphezulu kunye nokunciphisa. Kwangaxeshanye, ikwanendlela ekhethekileyo yokutshaja kabini yokutshaja ngokuthe ngqo kunye nokutshaja ngaphandle kwamacingo. Imowudi yokutshaja ngokuthe ngqo ifanelekile kwiindawo eziqhelekileyo zokuvelisa; Imowudi yokutshaja okungenacingo ilungele ukukhuseleka kothuli kunye nemeko-bume enobungqina bokudubula.

Iimpawu zoyilo olusebenzayo lwe-rack yelori ye-shuttle yeendlela ezine ze-haigris pallet zimi ngolu hlobo lulandelayo:

Ukuqhubekeka kwe-Breakpoint: xa isithuthi sisenza umsebenzi wokulayisha kunye nokukhulula, ngenxa yokungaphumeleli kwexesha elifutshane le-hardware efana nokuphepha umqobo kunye nokuqhawula inethiwekhi, isithuthi siya kuqhubeka ngokuzenzekelayo ukwenza umsebenzi ongagqitywanga ngaphandle kokungenelela komntu emva kokulinda kwindawo yokuqala de ukungaqhelekanga kuyapheliswa.

Ukutshaja ngokuzenzekelayo kunye nokubuyela emsebenzini: xa isithuthi siphantsi kunexabiso eliphantsi lebhetri elibekiweyo, ulwazi olufanelekileyo lwebhetri luya kulayishwa ngokuzenzekelayo kwii-WCs, kwaye ii-WC ziya kuthumela isithuthi ukwenza umsebenzi wokuhlawula. Emva kokuba isithuthi sihlawuliswe kwixabiso elimiselweyo lamandla, ulwazi olufanelekileyo lwamandla luya kulayishwa ngokuzenzekelayo kwii-WC, kwaye ii-WC ziya kuthumela isithuthi ukuba siqalise umsebenzi.

Umbono wePallet: isithuthi sinemisebenzi ye-pallet centering calibration kunye nokufumanisa i-pallet

Umbono womqobo: isithuthi sinomsebenzi wokubona umqobo kwiindlela ezine, kwaye sinokuphepha imiqobo kumgama omde kwaye sime kumgama omfutshane.

Ukubona ubushushu bebhetri: Ibona ubushushu bebhetri kumzimba wesithuthi ngexesha lokwenyani. Xa ubushushu bebhetri bugqithise kumda obekiweyo ophezulu, ibuyisela ulwazi olungaqhelekanga lobushushu bebhetri kwiWCS ngexesha lokwenyani. I-WCS ithumela izithuthi kwisikhululo esikhethekileyo ngaphandle kwendawo yokugcina impahla ukunqanda umlilo.

Umsebenzi wokubuyisela umva kwi-situ: qaphela ukubuyisela umva kwi-situ yomzimba wesithuthi ngokutshintsha amavili ahambelanayo macala omabini.

Indlela emine yokuhamba: inokuhamba kumacala amane endlela enikezelweyo yendawo yogcino-ntathu kwaye ifikelele kuyo nayiphi na indawo echongiweyo yendawo yokugcina impahla phantsi kokuthunyelwa kweWCS.

Ukulinganiswa kwesikhundla: Ukufunyanwa kweenzwa ezininzi, ezongezwa ngekhowudi ye-tunnel-dimensional ye-tunnel, ukuphumeza indawo echanekileyo.

Imowudi yokulawula ukuthunyelwa ngobukrelekrele: Imowudi ye-WCS ye-intanethi yokuthumela ngokuzenzekelayo, imowudi yokusebenza yokulawula kude kunye nemo yokugcinwa.

Imo yokulala nokuvuka: emva kokulinda ixesha elide, faka imowudi yokulala ukugcina amandla. Xa kufuneka isebenze kwakhona, iya kuvuka ngokuzenzekelayo.

Uhlangulo lonikezelo lwamandla olungxamisekileyo: phantsi kweemeko ezingaqhelekanga, xa amandla ebhetri engu-zero, sebenzisa umbane ongxamisekileyo, vula i-motor brake, kwaye uhambise isithuthi kwindawo yokulungisa ehambelanayo.

Umboniso wesimo kunye ne-Alarm: izibane zokubonisa isimo zifakwe kwiindawo ezininzi zesithuthi ukubonisa ngokucacileyo iimeko ezahlukeneyo zokusebenza zesithuthi. I-buzzer ifakelwa ukunika i-alam kwimeko yokusilela kwesithuthi.

Ukubona ukutshaja: xa isithuthi sifika kwindawo yokutshaja, ukushaja okungaqhelekanga kwenzeka ngexesha lokutshaja, kwaye ulwazi olungaqhelekanga lubuyiselwa kwi-WCS ngexesha langempela.

Ukufunxa ukothuka kwesithuthi: amavili akhethekileyo e-polyurethane asetyenziselwa ukumelana noxinzelelo, ukumelana nokunxiba, ukumelana noxinzelelo kunye nokufunxa ukothuka.

Ixesha lokuposa: Aug-25-2022