Njengekhonkco elibalulekileyo lokuphucula ukusebenza kakuhle, inkqubo yokugcina izinto ekrelekrele iphantsi kohlaziyo oluzenzekelayo nobukrelekrele kunye nenkqubo yohlengahlengiso ukuze kuphunyezwe ukwaneliseka kwabathengi. Kutshanje, umenzi weshelufu yokugcina i-hagerls uphehlelele isisombululo se-automation ye-automation edibanisa umzi-mveliso kunye nendawo yokugcina impahla, ebonelela ngamava apheleleyo ezinto ezizenzekelayo ezigquma indawo yokugcina impahla, ulawulo lwendawo yokugcina impahla, ukuchola nokusasazwa, ukulayishwa kunye nokukhulula, kunye nokuthuthwa kunye nokujikeleziswa kweemveliso / iimveliso ezigqityiweyo. Phakathi kwabo, uhlobo lwebhokisi yokugcina irobhothi ngokuzimeleyo ephuhliswe yi-hegerls iye yabonakala ngokuthe ngcembe kumbono woluntu. Kwangaxeshanye, iye yatsala ingqalelo ebanzi ngokusebenza kwayo okugqwesileyo kunye nentsebenziswano ebhetyebhetye yokusebenza.

Ukwahluke kwi-"shelf to person" ye-AGV efihlakeleyo kunye nezisombululo zokwakha izindlu zokugcina iimpahla, inkqubo yerobhothi yokugcina ibhokisi yobuncwane ithatha "isikhongozeli" njengeyunithi yokubonelela ngesikhongozeli esisebenzayo kumntu kunye nezisombululo ezizenzekelayo zenkqubo. Ngondoqo we-algorithm ye-AI, inkqubo yokucwangcisa iirobhothi ezininzi kunye nobunye ubuchwephesha, ukuphathwa ngobukrelekrele, ukukhetha kunye nokuhlelwa kweempahla kuyafezekiswa, okukhawulelana ngokukhawuleza neemfuno zokwenza i-elektroniki kunye namanye amashishini ekuchongeni ngokuchanekileyo kunye nokuphatha indawo yokugcina kunye nekhonkco lolungiselelo. Ngelixa unikezela ukuguquguquka kwendawo yokugcina kunye nokuqonda ngokukhawuleza ukuzenzekelayo, ukuxinwa kokugcinwa kwandiswa ngama-80% -130% kwaye ukusebenza kakuhle komntu kwanda ngamaxesha angama-3-4.

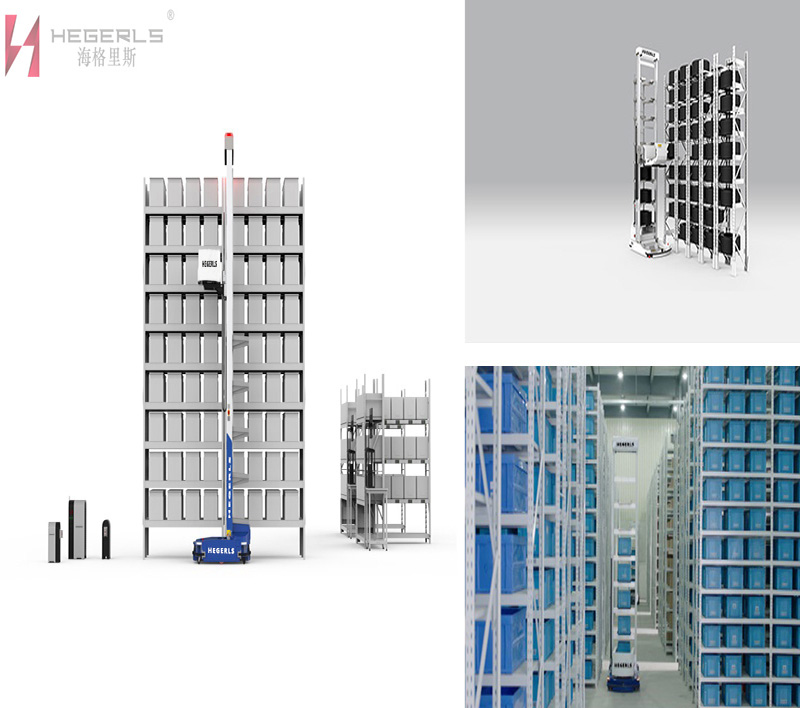

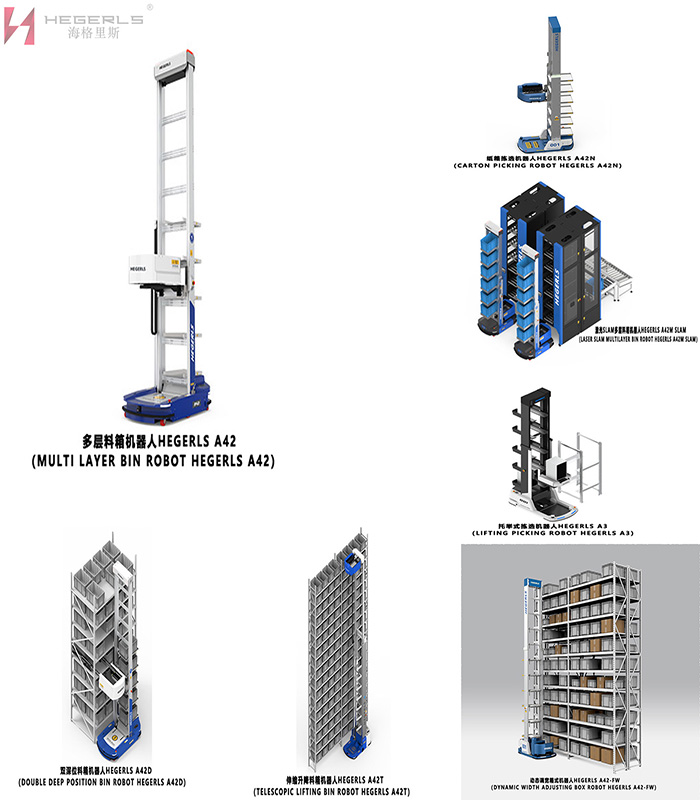

Okwangoku, uluhlu olutsha lwebhobhothi yokugcina ibhokisi yobuncwane eyasungulwa yinkampani yethu ibandakanya i-robot ye-A42 ye-multi-layer bin, i-double deep bin irobhothi i-a42d, i-carton yokuhlela irobhothi i-a42n, i-telescopic yokuphakamisa i-bin robot i-a42t, i-laser slam bin irobhothi i-A42 slam. Inkqubo entsha yerobhothi yokugcina ibhokisi yobuncwane yolu chungechunge iya kusebenza ngcono kwizicelo ezininzi zokuxazulula iintlungu ezahlukeneyo zokugcina.

Iimpawu ze-hegerls igugu inkqubo yerobhothi yokugcina ibhokisi

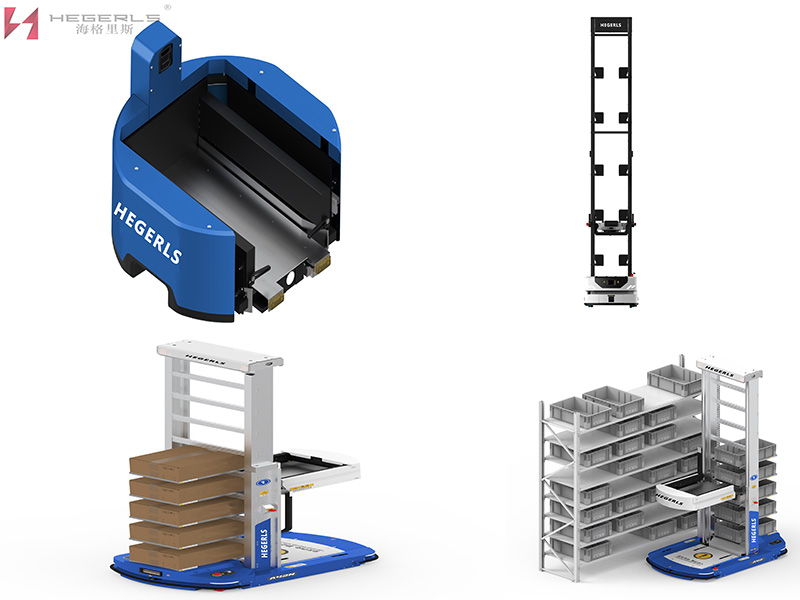

I-hegris hegerls i-robot yokugcina ibhokisi yokugcina i-robot inemisebenzi yokukhetha kunye nokuphatha okuhlakaniphile, ukuhamba ngokuzimeleyo, ukuphepha umqobo osebenzayo kunye nokutshaja ngokuzenzekelayo. Ineempawu zokuzinza okuphezulu kunye nokusebenza okuchanekileyo. Ingathatha indawo yokufikelela okuphindaphindiweyo, okuchitha ixesha kunye nomthwalo onzima wezandla kunye nomsebenzi wokuphatha, ukuqonda "impahla ebantwini" esebenzayo kunye nobukrelekrele, kwaye iphucule kakhulu ingxinano yokugcina kunye nokusebenza ngesandla kwendawo yokugcina impahla.

Iinzuzo ezintandathu ze-hegerls zigcina ibhokisi yokugcina irobhothi

1) Ukuchola ngobukrelekrele kunye nokuphatha

Ukuchola ngokuzimeleyo, ukuphatha ngobukrelekrele, ukukhangela okuzimeleyo, ukutshaja okuzimeleyo, ukuchaneka kwendawo ephezulu;

2) Ukugcinwa okubanzi kwe-Ultra

Uluhlu lokugcina lugubungela i-0.25m ukuya kwi-8m indawo ye-dimensional emithathu;

3) Isantya esiphezulu sentshukumo ezinzileyo

Umthwalo opheleleyo kunye nesantya sokungabikho komthwalo ukuya kwi-1.8m / s;

4) Ukuphathwa kweekhonteyina ezininzi

Irobhothi nganye inokufikelela kwiikhonteyina ezisi-8 ngexesha elinye;

5) Unxibelelwano lwenethiwekhi engenazingcingo

Inkxaso ye-5GHz ibhendi ye-Wi-Fi yokuzulazula ukuqinisekisa ukusebenza ngokukhululekileyo komqobo;

6) Ukhuseleko oluninzi

Inemisebenzi emininzi yokhuseleko, njengokubona imiqobo, ukuphepha umqobo osebenzayo, ukuchasana nokungqubana, i-alamu kunye nokuyeka ngokukhawuleza;

7) Ukukhetha imodeli ezininzi

Ezinye iimodeli ziyahambelana neebhokisi / imigqomo kunye nezikhongozeli ezinobungakanani obuninzi;

8) Ukulungelelaniswa okuguquguqukayo kweemveliso

Ukuxhasa iimfuno zokwenza ngokwezifiso ezifana nobude be-fuselage kunye nombala;

9) Isisombululo esifanelekileyo

Lungisa iskimu esisiso ngokweemeko ezahlukeneyo zesicelo.

U-Hegerls uzibophelele ekuboneleleni ngokufanelekileyo, okukrelekrele, okuguquguqukayo kunye nezisombululo ezizenzekelayo zokugcina izixhobo ngokusebenzisa iirobhothi kunye ne-algorithms yobukrelekrele bokwenziwa iminyaka emininzi, ukudala ixabiso kumzi-mveliso ngamnye kunye nendawo yokugcina impahla. I-Hagerls igxininise kwi-R & D kunye noyilo lwenkqubo yerobhothi yokugcina ibhokisi, kwaye iqonda i-R & D ezimeleyo yezinto eziphambili ezifana nomzimba we-robot, i-algorithm yokubeka ezantsi, inkqubo yokulawula, ukucwangciswa kwe-robot, inkqubo yokulawula ukugcinwa kwengqondo, phakathi kwayo ibhokisi yobuncwane. Inkqubo yerobhothi yokugcina isetyenziswe kumashishini ahlukeneyo afana nezihlangu kunye nempahla, i-e-commerce, i-electronics, amandla ombane, ukuvelisa, unyango lwezonyango, njl. % -130% kunye nokuphucula ukusebenza kakuhle kwabasebenzi ngamaxesha angama-3-4.

Uthelekiso phakathi kwendawo yokugcina impahla yemveli kunye ne-hegerls ibhokisi yokugcina ibhokisi yobuncwane:

Indawo yokugcina impahla yemveli: "abantu abafuna iimpahla" kunye nokusebenza kakuhle kogcino

Kwindawo yokugcina iimpahla yezandla, umsebenzi uchitha ngaphezu kwe-60% yexesha ehamba kwindawo yokugcina impahla, kunye nomyinge weekhilomitha ezingama-40 ngosuku. Nangona kunjalo, ixesha elichithwe ngokwenene ekuphatheni, ukugcina kunye nokukhetha kuphela i-akhawunti ye-40% yeeyure zokusebenza, kwaye ixesha elininzi lichithwa endleleni yokufumana iimpahla. Ngenxa yomgangatho ophantsi wolwazi kunye ne-automation, ukulawulwa kwendawo yokugcina impahla kunzima, ulawulo olusebenzayo luphantsi, kwaye ukusebenza kakuhle kwendawo yokugcina impahla kuphantsi. Nje ukuba imisebenzi emikhulu efana ne-"double eleven" kunye ne-"618" yande, kuya kufuneka abasebenzi abaninzi, kunye nokuqeshwa kwexeshana kwendawo yokugcina impahla kuya kwenzeka, okuya kwandisa kakhulu iindleko zabo zokusebenza kunye neendleko zokurenta kwendawo yokugcina impahla.

I-Heigris hegerls ixabise irobhothi yokugcina ibhokisi: "impahla ifika ebantwini" ukuphucula ukusebenza kakuhle kogcino

Inkqubo yerobhothi yokugcinwa kohlobo lwebhokisi - inkqubo kubao eyasungulwa yiHergels ibandakanya iimodyuli ezine: irobhothi kubao, iqonga lolawulo olukrelekrele, indawo yokusebenzela enemisebenzi emininzi kunye nemfumba yokutshaja ekrelekrele, enokuqonda ukukha okukrelekrele, ukuphatha kunye nokuhlelwa kwempahla yokugcina impahla. Xa kuthelekiswa nezinye izisombululo zerobhothi zokugcina, inkqubo ye-kubao inokufikelela kwindawo ephezulu yokugcina, isantya esiphezulu sokubetha kunye nokusebenza kakuhle kokuchola ngenxa yokuphuculwa kwe-granularity ukusuka "kwishelufu" ukuya "kwisikhongozeli". I-robot ye-Kubao inokuthwala ukuya kwiibhokisi zezinto ezi-8 ngaxeshanye, nto leyo ephucula ukusebenza kakuhle kwabasebenzi ngamaxesha angama-3-4, igubungela i-0.25-6.5m indawo yogcino-ntathu-ntathu, kwaye yandisa ubuninzi bokugcina nge-80% -130%.

Phakathi kwabo, iqonga lokulawula elihlakaniphile lingabizwa ngokuba "yingqondo yokugcina" yenkqubo ye-kubao, enokunceda indawo yokugcina impahla iqonde ulawulo ukusuka kwimiyalelo yamaphepha ukuya kwingcaciso yedijithali. Ngokusebenzisa i-docking kunye nenkqubo yokulawula indawo yokugcina impahla, kunokwenzeka ukuhlalutya idatha yoshishino yexesha elidlulileyo kwixesha lemisebenzi emikhulu yokukhangisa efana ne "double 11" okanye "618" ukwenza ukubala okuqhumayo kwangaphambili kunye nokusebenzisana. kunye nokuthengiswa kwangaphambili, ukuze kufezekiswe ucwangco lokucwila kwaye ulungiselele imfazwe kwangaphambili; Ngexesha elifanayo, ngokusekelwe kwi-platform ye-algorithm, inokuqonda kwakhona ukwabiwa komyalelo, ukwabiwa komsebenzi, ukucwangciswa kwendlela, ulawulo lwezithuthi, njl.

Ixesha lokuposa: Jun-24-2022