Njengoko imfuno yabathengi kushishino lwefayibha yeekhemikhali ithande ukuba yeyomntu kwaye yenziwe ngokwezifiso, kukho i-SKU eyongezelelekileyo, kwaye iimeko zokusebenza kolungiselelo zihlala zitshintsha, ezinokusebenza okuphezulu kokusebenza, zisebenzisa ngokupheleleyo indawo, zinokuhamba ngeendlela ezininzi ngapha nangapha. indlela, kwaye zilungiswe ngeemoto eziguquguqukayo ezineendlela ezine zokuthutha kunye nezipakishi kunye nezinye izitora ezizenzekelayo ezizisebenzelayo, ezithandwa ngamashishini amaninzi nangakumbi.

Malunga HEGERLS

IHebei Walker Metal Products Co., Ltd., eyayifudula ibizwa ngokuba yiGuangyuan Shelf Factory, yayiyinkampani yangaphambili eyayisebenza kushishino lweshelufu eMntla China. Kwi-1998, yaqala ukuthatha inxaxheba ekuthengisweni nasekufakweni kwezixhobo zokugcina iimpahla kunye nezixhobo. Emva kweminyaka engaphezu kwe-20 yophuhliso, ibe ngumboneleli wenkonzo odibeneyo odibeneyo odibanisa ukugcinwa kweprojekthi kunye noyilo lweprojekthi, izixhobo kunye nezixhobo zokuvelisa, ukuthengisa, ukudibanisa, ukufakwa, ukugunyaziswa, ukuqeqeshwa kwabasebenzi bolawulo lwendawo yokugcina impahla, inkonzo emva kokuthengisa, njl.

Ikwaseke i-brand yayo ethi "HEGERLS", iziseko zemveliso yaseka eShijiazhuang naseXingtai, kunye namasebe okuthengisa eBangkok, Thailand, Kunshan, Jiangsu naseShenyang. Inesiseko semveliso kunye nophando kunye nophuhliso lwe-60000 m2, imigca yemveliso yehlabathi engama-48, abantu abangaphezu kwama-300 kwi-R&D, imveliso, ukuthengisa, ukufakwa kunye nenkonzo emva kokuthengisa, kubandakanya abantu abaphantse babe ngama-60 kunye namagcisa aphezulu kunye neenjineli eziphezulu. Iimveliso kunye neenkonzo zeHGRIS zigubungela phantse amaphondo angama-30, izixeko kunye nemimandla ezimeleyo eTshayina. Iimveliso zithunyelwa eYurophu, eMelika, kuMbindi Mpuma, eLatin America, kuMzantsi-mpuma Asia nakwamanye amazwe nakwimimandla, kwaye zenze impumelelo ebalaseleyo phesheya kolwandle.

I-HEGERLS luyilo loyilo oluzenzekelayo oluzenzekelayo kunye nomenzi wezixhobo, kunye nemoto ye-shuttle yobuchwephesha, i-stacker kunye nabanye abavelisi. Kuzibophelele ekuboneleleni abathengi ngesicwangciso esisebenza ngokuzenzekelayo sogcino kunye nezisombululo zezixhobo. Njengomvelisi owaziwayo kunye namalungelo abenzi bobugcisa bezixhobo ezinxulumene ne-warehouse ezenzekelayo, i-HEGERLS ibonelele ngamaxabiso akhuphisanayo kunye neenkonzo ezigqwesileyo kwiindawo ezininzi zokugcina iimpahla, kunye nezixhobo zokusebenza ezihlakaniphile kunye neenkqubo zokulawula iindleko. Abathengi abasetyenziswa yi-automated warehouse bavela kwiinkalo ezininzi ezifana neekhemikhali, ukutya, unyango, oomatshini, ukugcinwa okubandayo, njl. Iimveliso ze-HEGERLS:

Ishelufu yokugcina: ishelufu ye-shuttle, i-cross beam shelf, i-four-way shuttle car shelf, i-pallet yeendlela ezine ze-shuttle car shelf, i-shelf ephakathi, i-shelf elula, i-pallet shelf, i-rotary shelf, i-shelf, i-stereoscopic warehouse shelf, i-attic shelf, i-shelf yomgangatho, Ishelufu yecantilever, ishelufu eshukumayo, ishelufu etyibilikayo, idrayivu kwishelufu, ishelufu yomxhuzulane, ishelufu yokugcina ephezulu, cofa kwishelufu, chola ishelufu yohlobo olukwindlela emxinwa, ishelufu yephalethi enzima, ishelufu yodidi lweshelufa, ithala lohlobo lwedrawa Ishelufu yohlobo lwe-attic, ishelufu yohlobo lokupakisha, ishelufu yenqanaba eliphezulu elinamacala amathathu, ishelufu yensimbi ye-angle yendalo yonke, ishelufu yohlobo lwecorridor, ishelufu yokubumba, ikhabhinethi eshinyeneyo, iqonga lentsimbi, ishelufu echasene nomhlwa, njl.

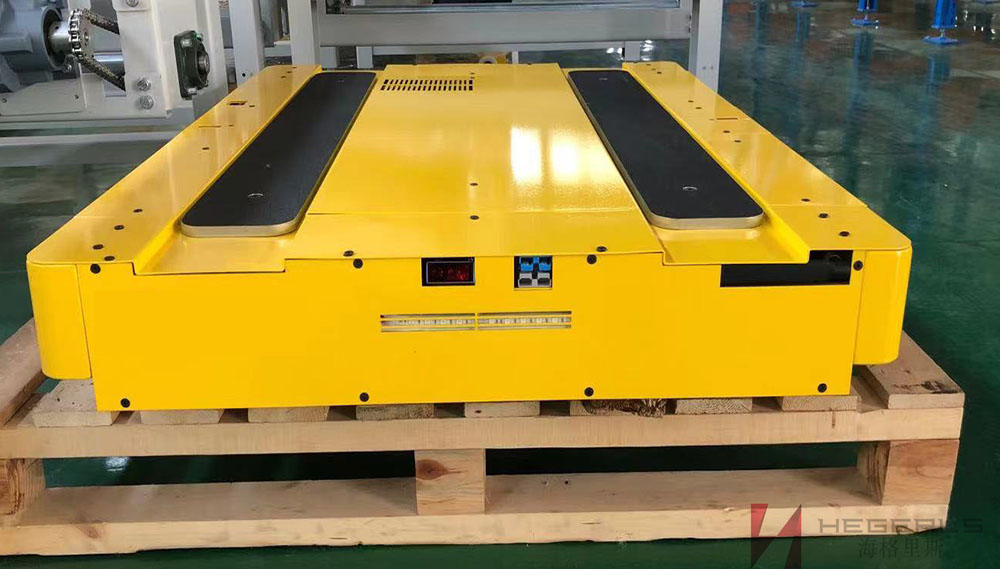

Izixhobo zokugcina: iqonga lensimbi, i-pallet yensimbi, ibhokisi yensimbi, isakhelo esilungileyo, ikheji yokugcina, i-isolation net, i-elevator, uxinzelelo lwe-hydraulic, imoto ye-shuttle, i-shuttle-way car, i-shuttle yabazali, imoto ye-shuttle-way, i-stacker, isahlulo sesikrini, ukukhwela imoto, ukuthuthwa okuhlakaniphile kunye nezixhobo zokuhlela, i-pallet, i-forklift yombane, i-container, ibhokisi ye-turnover, i-AGV, njl.

Uchungechunge olutsha lwerobhothi ekrelekrele: Uchungechunge lwerobhothi yeKubao, ebandakanya: i-robhothi yokuchola ibhokisi ye-HEGERLS A42N, i-robot yokuphakamisa i-HEGERLS A3, i-robot ye-double bin i-HEGERLS A42D, i-telescopic yokuphakamisa i-bin robot HEGERLS A42T, i-laser SLAM ye-layer multi-layer bin robot HEGERLS A42 SLAM, ezininzi -i-robot ye-bin ye-robot HEGERLS A42, i-robot eguquguqukayo yokulungelelanisa i-bin robot HEGERLS A42-FW, iqonga lolawulo oluhlakaniphile, indawo yokusebenza ye-Smart Charge Point.

Ugcino oluzenzekelayo lwestereoscopic: indawo yokugcina ishuttle stereoscopic, indawo yokugcina i-pallet stereoscopic, indawo yokugcina ishelufa enzima, indawo yokugcina izinto ezizenzekelayo, indawo yokugcina i-attic stereoscopic. indawo yokugcina i-stereoscopic , indawo yokugcina iyunithi yestirioscopic, ngendlu yokugcina stereoscopic, ifomathi yempahla yokugcina stereoscopic, i-automated yekhabhathi yokugcina stereoscopic, indawo yokugcina istrioscopic, ishelufu yestrioscopic yokugcina, ukukhetha isitora esistereoscopic, semi-automatic stereoscopic warehouse Linear guideway stereoway low, Traditional Indawo yokugcina isitiriyo ekumgangatho ophakathi, indawo yokugcina isitiriyo ekumgangatho ophakamileyo, indawo yokugcina isitiriyo ehlanganisiweyo, indawo yokugcina istereo enemaleko, indawo yokugcina istiriyo, indawo yokugcina istiriyo ejikelezayo, njl.

Inkqubo yolawulo lwesitora: inkqubo yolawulo lweodolo (OMS), inkqubo yolawulo lwendawo yokugcina iimpahla (WMS), inkqubo yolawulo lwendawo yokugcina iimpahla (WCS) kunye nenkqubo yolawulo lothutho (TMS). Inkqubo yokulawula indawo yokugcina impahla ebonelelwa yi-HEGERLS inokukhuthaza ukuphuculwa kokusebenza kakuhle kunye nokunciphisa iindleko zekhonkco lonke, kwaye iqonde "i-intelligent warehouse configuration integration".

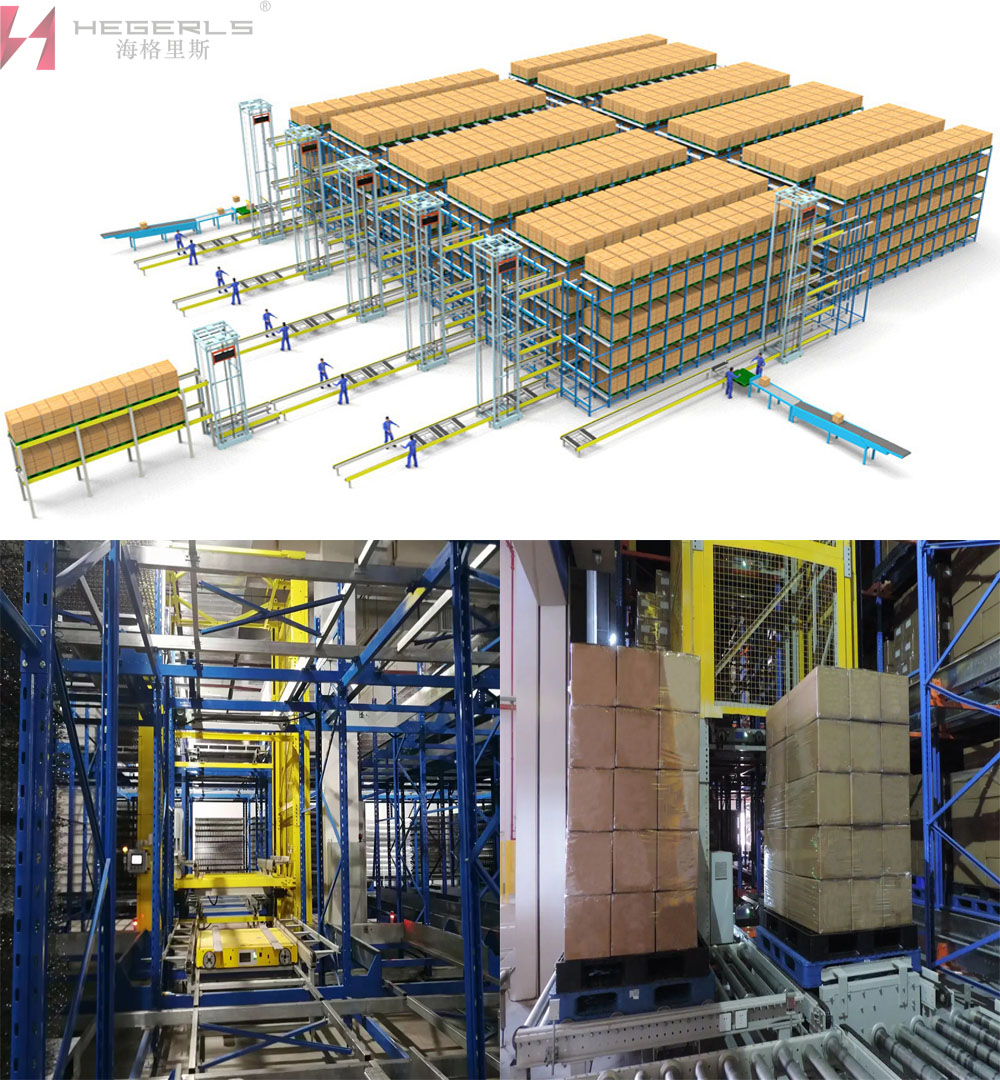

ULwakhiwo loLwakhiwo lweNdlela ezine Shuttle Imoto yeHaggis Roadway Stacker

Inkqubo yokugcina ingqiqo edibeneyo kunye nendlela yokulawula i-stacker kunye ne-shuttle yeendlela ezine inokwandisa ukusetyenziswa kwendawo, kwaye indlela yokusebenza yezixhobo izimele kwaye ayiphazamisi omnye nomnye. Ukulungiswa kwendlela yothutho kufezekiswa ngokucwangciswa kwendawo yokugcina impahla. Inkqubo yokugcina edibeneyo ehlakaniphile ye-stacker kunye nemoto yendlela ezine. Inkqubo yokugcina ixhotyiswe ngendawo yeshelufu kunye nendawo yokuhlela. Umzila we-stacker othe tye kunye ne-stacker iseti phakathi kwendawo yeshelufu kunye nendawo yokuhlela. Kukho uluhlu lweeshelufa zodidi lwengoma ezininzi ezicwangciswe kwindawo yeshelufu. Indawo yokugcina idiski enguziro kunye nendawo yogcino kunye nendawo yebuffer ephumayo isetiwe kufutshane nomzila wesitaki kwindawo yeshelufa, Umzila wokujikeleza wemoto eshukumayo kunye nemoto enendlela emine ebaleka kumzila wemoto eshukumayo ifakwe phakathi kwengoma enemigangatho emininzi. uhlobo lweeshelufa, kunye nendawo yokugcina ipleyiti yonke isetiwe kwelinye icala lendawo yesithinteli sogcino; Icala elinye lendawo yokuhlela kufutshane nomzila wesithinteli sixhotyiswe ngonothi wokususa indawo yebuffer, kwaye indawo yebuffer yokususa enguziro yahlulwe ngokuthe tye kunye nendawo ekhululekileyo yesithinteli sediski kunye nendawo yokuhambisa ngaphandle. Abahambisi abaliqela bafakelwe ixesha elide kwindawo yokuthutha ephumayo kunye nendawo ekhululekileyo yedisk buffer, ngokulandelelanayo. Isiphelo sendawo yokuthutha ephumayo ifakwe ngokunqamlezileyo kunye nomatshini wokudlulisela ijack, kwaye elinye icala lendawo ye-zero yokususa i-zero ixhotyiswe ngerobhothi yokususa i-zero kunye ne-longitudinal yokususwa kwe-zero kunye nokulayisha ibhanti lokuhambisa, Indawo ye-zeroing buffer nayo idityanisiwe. kunye nebhanti yokuhambisa yetreyi engenanto kunye nebhanti lokuhambisa longitudinal yokugcina impahla.

Kwangaxeshanye, isitokhwe esingaphakathi/kwindawo yesithinteli sibandakanya isitokhwe kwindawo yesithinteli kunye nendawo yesithinteli sesitokhwe esetwe ngamaxesha athe tye. Isitokhwe kwindawo yesithinteli sihambelana nendawo yesithinteli sedisk eninzi, kwaye indawo yesithinteli sesitokhwe ihambelana nendawo yothutho yokuphuma kwesitokhwe. Ngeendlela ezine zemoto ye-shuttle ye-Haggis roadway stacker, ininzi ye-stackers iphakamisa i-stackers eyongeziweyo kabini. (Ngokuqinisekileyo, kukho kwakhona i-stackers yokwandisa enye, enokukhethwa ngokweemfuno zabathengi.) Iskena sokuqaphela ibhakhowudi sikwafakwe kwindawo yerobhothi yokususa i-zero. Inkqubo yemoto yeendlela ezine zohlobo lwe-Haggis tunnel stacker iphinda ibandakanye inkqubo yokulawula indawo yokugcina impahla, edibaniswa nemoto yendlela ezine, i-stacker kunye ne-robot ye-disassembly.

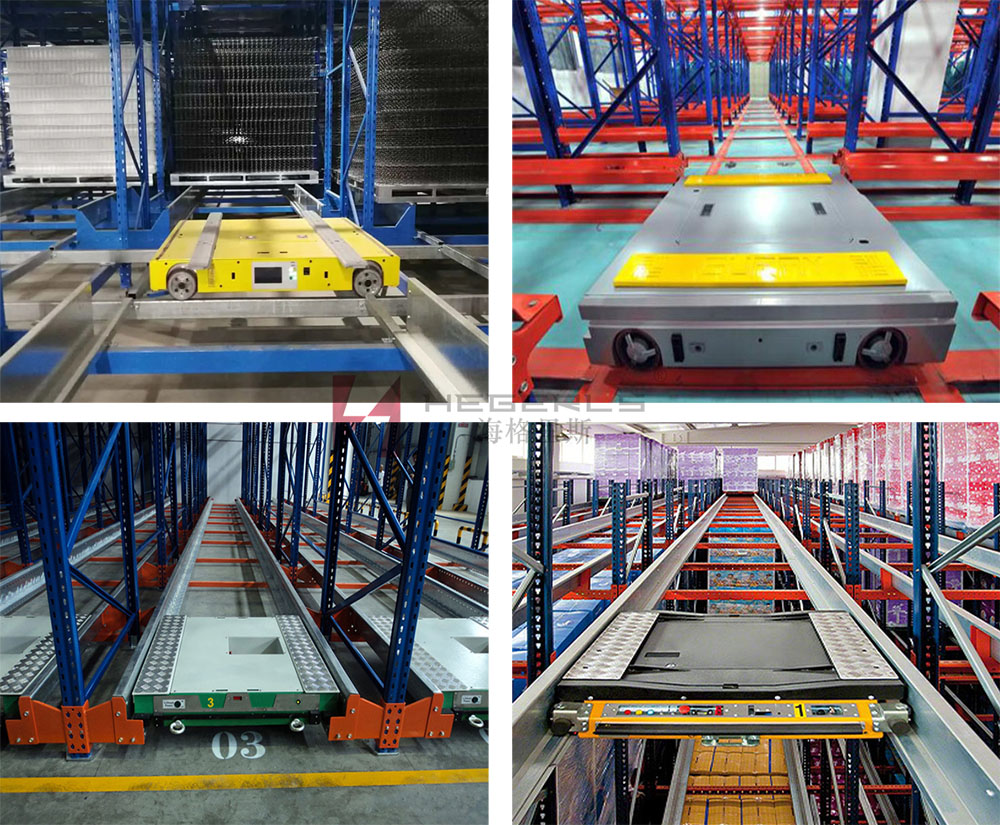

Isebenza njani isithuthi esineendlela ezine kwiHagrid Roadway Stacker?

Xa iimpahla zigcinwe kwindawo yokugcina impahla, i-pallet yonke yempahla ithunyelwa kwindawo yonke yokugcina i-pallet yendawo yeshelufu ngokusebenzisa ibhanti yokuhambisa impahla kunye ne-stacker, emva koko yonke i-pallet yempahla ihanjiswa kwi-multi-layer ehambelanayo. umzila kaloliwe kwi-inventri yemoto yendlela ezine; Xa uthatha iimpahla, isithuthi esinendlela emine siya kuthutha yonke ipalethi yeempahla ukusuka kwirekhi ye-multi-layer kaloliwe ukuya kwindawo yebuffer yangaphakathi nephumayo, kwaye isitaki siya kudlulisela iimpahla kwindawo yothutho ephumayo yendawo ye-zeroing buffer. , kwaye emva koko udlulisele kwiindawo zokususa irobhothi ngokusebenzisa umthumeli kunye nomatshini wokudlulisa i-jacking, kwaye iindawo ziya kususwa ngokupheleleyo ngamalungu e-robot yokususa, kwaye iindawo eziseleyo ziya kuqhubeka zithuthelwa kwiindawo zokususa i-buffer zide zisuswe. zisuswa ngokuphindaphindiweyo xa zilinde ukuhanjiswa okulandelayo, Ekupheleni kokuthunyelwa ngalunye, iitreyi ezishiyekileyo ezishiyekileyo ziya kudluliselwa kwindawo yebuffer yangaphakathi nephumayo ngestacker, emva koko iimpahla zetreyi ezivulekileyo ziya kudluliselwa kwaye zigcinwe kwiqanda. indawo yokugcina i-tray yendawo yeshelufu nge-shuttle yeendlela ezine. Ngaphambi kokuba i-plate yonke ihlanjululwe yi-robot ye-disassembly, ulwazi lwe-pallet yonke yempahla luqinisekiswa emva kokuskena nge-scanner ye-barcode, kwaye ubuninzi bempahla buqinisekiswa ngokweenkcukacha zomyalelo. Ngaphezu koko, iimpahla zomyalelo emva kokuchithwa kwe-robot ye-disassembly zidluliselwa kwindawo yokulayisha nge-disassembly kunye nokulayisha ibhanti yokuhambisa. Xa ipalethi engenanto ichithwa yirobhothi yokuqhaqha, iya kuhanjiswa kwaye ihlaziywe kwibhanti yokuhambisa ipalethi engenanto, ipakishwe sisitaki sepalethi kwaye emva koko igcinwe kwindawo yokugcina impahla kwakhona ngebhanti lokuhambisa.

Inzuzo enkulu yeendlela ezine ze-shuttle ye-Haggis roadway stacker kukuba ithatha i-design modular kunye nokuqina okuqinileyo, oko kukuthi, ingxaki yendawo enye ayiyi kubangela ingxaki yendawo yokugcina impahla; I-scalability eyomeleleyo, kulula ukuyitshintsha ukuthunyelwa nangaliphi na ixesha, kwaye kulula ukuyiphinda inkqubo yomsebenzi ngokweenguqu zeshishini. I-buffer kwindawo yokuthumela, i-robot idibanisa i-disks eseleyo eseleyo, kunye ne-buffer phakathi kweediski ze-spare kunye nee-tray ezingenanto ziqokelelwa kwaye zifakwe, kwaye ulawulo lwenza umjelo ojikelezayo; Ulwakhiwo lokuqukuqela komjikelo nalo lwenziwe phakathi kweendawo ezigcina ibhetshi yokugcina impahla kunye nesitaki.

Indlela ye-4 yemoto yohlobo lwe-Haggis lane stacker inokuqonda yonke inkqubo ephumayo imisebenzi efana nokupakisha kunye nokugcinwa kwezinto ngeerobhothi zemizi-mveliso, i-buffered batch outout, i-buffered batch destacking, ukugcinwa okwethutyana kweetreyi ezininzi eziseleyo, ukuqokelela kunye nokulawulwa kweetreyi ezingenanto. , kwaye uqonde imisebenzi yokuhlelwa kwe-anthropomorphic, ukuhanjiswa kwempahla, ukumisa kunye nokubuyela kwindawo yokugcina impahla. Ukusebenzisa iteknoloji yokufumanisa kunye nokuhlalutya kwe-wms, i-wcs, kunye ne-plc, i-4-way-shuttle car kunye ne-stacker inokutshintsha iileyile phezulu nangaphantsi, Qonda inkqubo yokulawula inkqubo eguquguqukayo kunye nokukhawuleza kwempahla ngaphakathi nangaphandle kwendawo yokugcina impahla. Iishelufu zihlanganiswe kwiimodyuli, ezinokuqonda indawo yokugcina i-multi-layer.

Ixesha lokuposa: Dec-06-2022