Ukuqhuba kwishelufu kubhekiselele kugcino lweepaliti nganye nganye ukusuka ngaphakathi ukuya ngaphandle. Ijelo elifanayo lisetyenziselwa ukufikelela kwi-forklift, kwaye ubuninzi bokugcina bulungile kakhulu. Nangona kunjalo, ngenxa yokungafikeleleki kakuhle, akukho lula ukuphumeza ulawulo lweFIFO. Ekubeni i-forklift kufuneka isebenze ngokucokisekileyo xa uhamba kwi-rack yonke, kungcono ukuqhuba kwi-rack kunye ne-4 layers kunye ne-3 ukuya kwi-5 ikholomu.

Qhuba kwi-rack yokwakheka

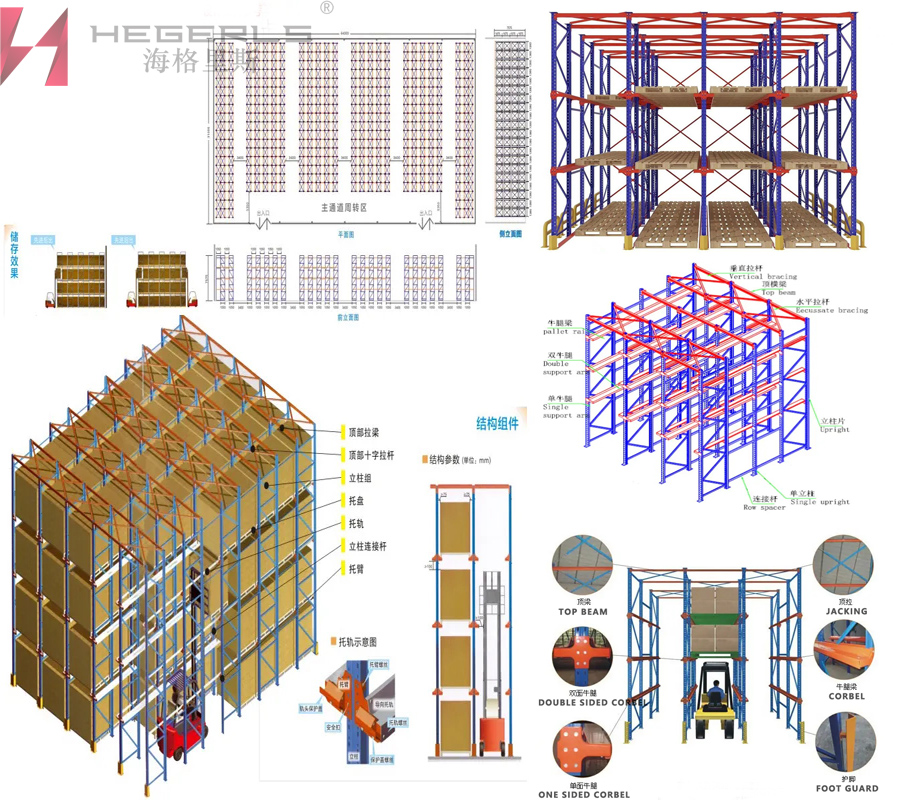

Izixhobo zokuqhuba kwi-rack zibandakanya: i-corbel (esona sidibanisi esiphambili phakathi kwe-corbel kunye nekholomu ye-rack, icala elinye kunye necala eliphindwe kabini), i-corbel (i-shelf yenkxaso ephambili yokugcina impahla), umqadi ophezulu (i-connector kunye ne-stabilizer ye-rack ikholamu), utsalo oluphezulu (isinxibelelanisi kunye nesizinzi sekholamu ye-rack), ukutsalwa ngasemva (isinxibelelanisi kunye nesizinzi sekholamu ye-rack, esetyenziselwa uyilo lwe-rack yendlela enye), umlindi weenyawo (inxalenye ekhuselayo yangaphambili ye-rack) Iintsimbi zokukhusela. (iindawo zokukhusela zamashalofu xa iiforklift zingena endleleni), njl.

Ngokukodwa, i-drive kwi-rack, eyaziwa ngokuba yi-corridor rack kunye ne-rack, sisakhiwo se-rack yamacango amaninzi edibanisa imigca emininzi ye-racks yendabuko okanye i-lattice columns izakhiwo ngendlela eqhubekayo ngaphandle kokwahlulwa kwetshaneli kunye nokuqhubeka, kwaye i-pallet igcinwe kwi-rack. Umqadi we-cantilever kwiyunithi kwaye ugcinwe kwicala elinzulu; Olu hlobo lweshelufu luneempawu zomthamo omkhulu wokugcinwa kwempahla kwiyunithi nganye, kwaye ifanelekile ukugcinwa kunye nokusebenza kwenkqubo yezinto kunye nebhetshi enkulu, iintlobo ezimbalwa kunye nokuhamba okukhulu, okufana neziselo, iimveliso zobisi, ifriji ephantsi yokushisa. ukugcinwa, izixhobo zendlu, iikhemikhali, iimpahla, icuba kunye nezinye iziganeko ezineendleko eziphezulu zokugcina indawo, kodwa akufanelekanga ukugcinwa kwezinto ezide kakhulu okanye ezinzima kakhulu; Xa kuthelekiswa nolwakhiwo lweshelufu yetrayi yomnqamlezo, indawo yokusetyenziswa okusebenzayo kwishelufu inokunyuswa ukuya kuma-90% kakhulu, kwaye izinga lokusetyenziswa kwesiza nalo linokufikelela ngaphezulu kwe-60%, enokufikelela kubuninzi bomthwalo wokulayisha. Kweyona nkqubo yesicelo, i-drive kwishelufu inokusetyenziswa ngokudityaniswa nezinye izakhiwo zeshelufu zodidi oluninzi ukuhlangabezana ngokupheleleyo neemfuno ezahlukeneyo zokugcinwa kwesiza somthengi.

Ke, siyithenga njani idrayivu kwishelufu ngaphambi kokusetyenziswa kwemihla ngemihla? Ngoku, masilandele umenzi weshelufu yeHigelis ukuze sifumanise!

Ukuthengwa kwe-drive kwiishelufu kufuna ukuqonda okucacileyo kwe-pallet unitization yezinto ezigciniweyo

Ubume kunye nobukhulu be-drive kwi-shelf buchongwa zizinto zokugcina, izixhobo zokuphatha kunye nobukhulu beyunithi ye-pallet; Ngenxa yobuninzi obuninzi bokugcinwa kunye nokusebenza okuphezulu kokuguqulwa kwe-drive kwindawo yokugcina i-shelf, isakhiwo sensimbi yeshelufu sisondele ekusebenzeni kunye neendlela zokugcina. Xa kuthelekiswa nezinye iintlobo zeeshelufu, kukho iinkcukacha ezithe kratya kunye neemfuno ezikumgangatho ophezulu wepallet kunye neyunithi yephalethi. Kuyimfuneko ukwenza ukhetho olusebenzayo ngokweempawu zokunyanzeliswa kwephalethi, ngokukodwa kwiipalati zexesha elide, umthwalo we-static kunye oguqukayo we-pallet kufuneka uhlolwe Umthwalo kwiishelufu kunye nendlela iimpahla ezibekwe ngayo kwiipalati; Ngelo xesha, ishelufu yolu didi nayo ineemfuno eziphezulu kwiyunithi yokupakishwa kwempahla, ukwenzela ukunciphisa izinga lomonakalo wempahla egciniweyo kunye nokuphucula ukusebenza kakuhle kunye nokhuseleko lokuthunyelwa; Impahla ye-pallet united akufanele ibe nkulu kakhulu okanye inzima kakhulu. Ngokuqhelekileyo, ubunzima kufuneka balawulwe ngaphakathi kwe-1600KG, kwaye i-pallet span ayifanele ibe nkulu kune-1.5M. Ukongeza, ngohlelo lokupakisha oludibeneyo lweempahla ezigciniweyo, umthwalo onzima kunye nempahla yokuphakama komgangatho omkhulu kufuneka igcinwe kwindawo yokugcina ephantsi yedrayivu kwisakhiwo seshelufu kangangoko kunokwenzeka, enokunciphisa ngempumelelo iziko lokugcina lomxhuzulane weshelufu. inkqubo kunye nokuphucula ukugcinwa kunye nokuzinza kwenkqubo.

Ukuthengwa kwe-drive kwi-shelf lattice isakhiwo esithe nkqo kuxhomekeke kwisakhiwo sekholamu ye-lattice

Ulwakhiwo lwekholamu ye-lattice eyenzelwe, iveliswe kwaye yenziwe ngumenzi weshelufu ye-Higelis ikwasona sakhiwo siqhelekileyo kwi-drive kwisakhiwo seshelufu. Ikakhulu iqulunqwe lilungu lekholomu (ikholamu yefreyim) kunye nelungu lewebhu (ibrace enqamlezileyo kunye nebrace diagonal). Ilungu lekholomu lithatha ubukhulu becala uniaxial symmetric ebandayo-eyakheke olucekethekileyo enemingxuma yecandelo ikholamu yentsimbi. Ilungu lewebhu lithatha kakhulu intsimbi epholileyo yecandelo elibunjwe nguC. Ilungu lekholomu kunye nelungu lewebhu lidityaniswe ngeebholiti ukwenza i-diagonal bar lacing structure. Uxinzelelo lwekholamu yesakhelo lubangelwa umnqamlezo I-diagonal braces yabelana ngenxalenye yesakhiwo kwaye iyancipha kancane. Isakhiwo sonke sikhuselekile ngaphandle kokuqwalasela imiphumo emihle ye-transverse braces kunye ne-diagonal braces; Ulwakhiwo oluqhelekileyo lwelungu lekholomu liyi-uniaxial symmetric cold-formed thin-walled section perforated section yentsimbi ikholamu. Xa uthwala umthamo womthwalo, ulungele ukugoba kunye ne-torsional buckling, okunciphisa umthamo wokuthwala. Unokongeza ama-battens kwicala elivulekileyo ukwenzela ukuba lisondele kwicandelo elivaliweyo, elinokuphucula kakhulu umthamo walo wokuthwala. I-XX yokugoba ukuzinza kolu hlobo lwecandelo lumisela ngokuthe ngqo umthamo wokuthwala kunye nokuzinza kwesakhiwo sokuqhuba kwi-shelf. Ngokufanayo, esi sakhiwo sekholomu ye-lattice kwakhona yintsika yecala yesakhiwo se-portal ye-drive kwi-shelf. Ngenxa yokuba ukugoba ukugoba kunye nokuqina kwe-torsional yamalungu esakhiwo se-portal sincinci, ukuqina okupheleleyo kwesakhiwo kubuthathaka. Ukuphakama kokuphakama, ukuthoba ukuthwala ukuzinza, kunye nokukwazi ukumelana nokugoba kunye ne-torsional buckling kuya kuncitshiswa kakhulu. Iiparamitha zobude bengalo ye-cantilever kunye nobunzima be-tray yokuthwala ngabadlali abathe ngqo abasebenzisa i-torque egobayo kwisakhiwo sekholamu ye-lattice, I-torque eyongezelelweyo yokugoba eyenziwe kunye nobude be-cantilever ichaphazela ukugoba kunye namandla okujikeleza kwekholomu ye-rack.

Okwangoku, uhlalutyo lwesakhelo sokwakheka kwenkqubo lutshintshwa ngokubalwa kwamandla, ukuqina kunye nokuzinza kwekholamu ye-lattice ekuyilweni kwe-drive kwi-shelf. Ngenxa yokuba ikholomu ye-lattice ngokubanzi iqulunqwe ngamacandelo amancinci kwaye amancinci, ukuqina kunye nokuzinza kwesakhiwo sekholomu kwi-drive kwisakhiwo seshelufu kuchaphazeleka kakhulu ngumlinganiselo wayo we-slenderness, ukuzinza kwayo kwesakhiwo buthathaka, kwaye kukho iindlela ezimbalwa zokuqinisa izakhiwo ezinokuthi . ziqondwe, Kukwanzima ukufezekisa. Okwangoku, imakethi ikhulisa umjelo wokusebenza ngokusebenzisa iilori ezishuthayo ze-WAP ukuba zithathe indawo yokungena kunye nokuphuma kwendlela yokusebenza yetonela yezinye izixhobo zokuphatha ezifana ne-forklifts, kwaye inokwenza kube lula ukuqiniswa komqadi othe tye kwikholamu yesakhelo kwindawo esebenzayo engaphantsi kwendawo yokugcina. indawo, enokwandisa kakhulu umlinganiselo we-slenderness wekholamu yesakhelo; Okanye kwindawo engaphakathi yempahla yokungena kunye nokuphuma kwendlela, uyilo lokuqhuba kwisakhiwo seshelufu luphuculwe ngesakhiwo esiqhelekileyo seshelufu ye-pallet, ukwenzela ukuba kuphuculwe umthamo wokuthwala kunye nokuzinza kwesakhiwo seshelufu ngokubanzi, eya kuba yenye yeendlela eziphambili zokulungiselela ukuqhubela phambili kwisakhiwo seshelufu kwixesha elizayo.

Ixesha lokuposa: Sep-19-2022