china Warehouse Storage Heavy Duty single nzulu kwaye kabini nzulu Steel ekhethiweyo Pallet Racking System

Ukufikelela komntu ngamnye kuzo zonke iipalethi ukuya kubude obugcweleyo bendawo yokugcina impahla

Ujikelezo olulula lweStokhwe luphunyeziwe

Ulungelelwaniso lwe-beam olulula luhlala kwiindawo eziphakamileyo zepallet.

Iyahambelana neendlela ezininzi zokuphatha izixhobo

Ukunyamezela okuqhelekileyo kwemigangatho xa kusetyenziswe ukuya kwi-10m ukuphakama

Iipaliti ezisezantsi zinokubekwa phantsi.

95% Umyinge ophezulu wokusetyenziswa kweendawo.

1.Ukuqaliswa kwemveliso ye-pallet rack ekhethiweyo

I-HEGERLS i-Selective Pallet Racking sisisombululo esona sisombululo seendawo zokugcina iimpahla apho kuyimfuneko ukugcina uluhlu olubanzi lwamanqaku kwiipalati. Inika ukufikelela ngokuthe ngqo kuzo zonke iipalati zokufikelela kwi-100% kunye nokujikeleza kakuhle kwempahla. Iipalethi zinokufumaneka, zifikeleleke kwaye zihanjiswe ngabanye ngokubonelela ngokuphathwa ngokukhawuleza kwempahla ephalethisiwe. Inika uhlengahlengiso olulula lwe-beam kwaye ivumela ukuphakama kwepallet eguquguqukayo.

2.Iparamitha yemveliso.

| Uthe tye | Umqa webhokisi | Isikhewu sokukrola | Umkhuseli othe tye | Umqobo osecaleni |

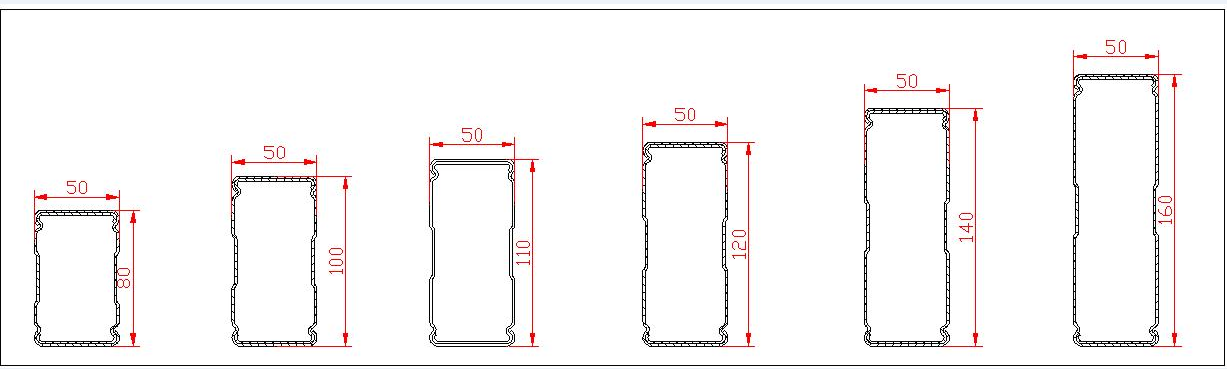

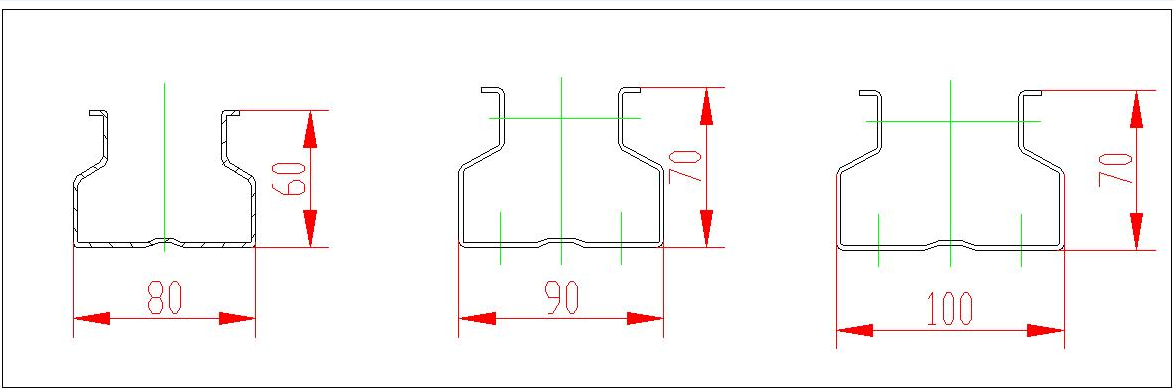

| 80*70/90*70/100*70 | 80*50/100*50/120 *50/140*50 | 30*50/40*80 | H300/H500 | D76*2.5 |

3.Uphawu lwemveliso kunye nesicelo

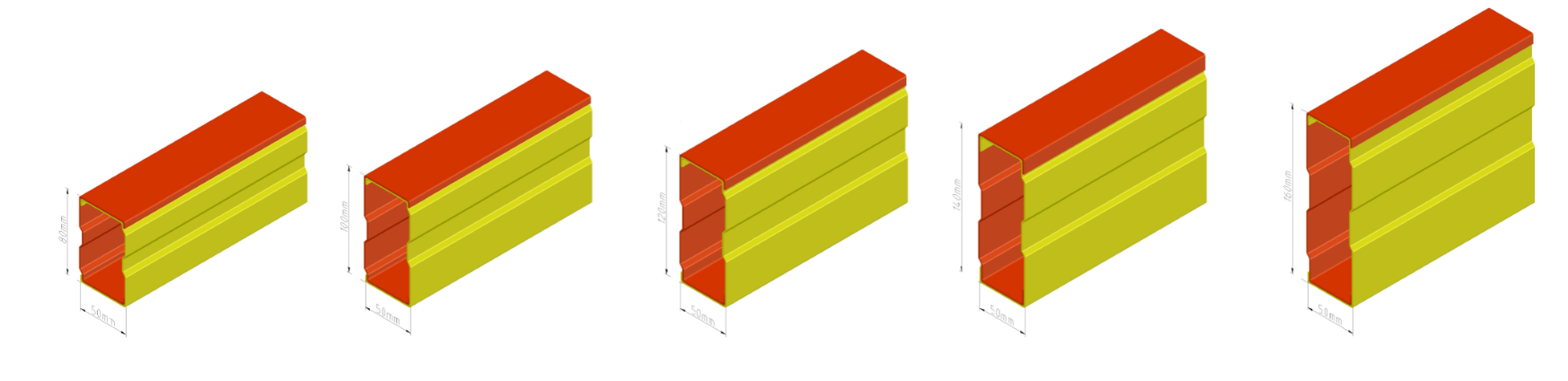

3.1 Iinkcukacha zebhokisi

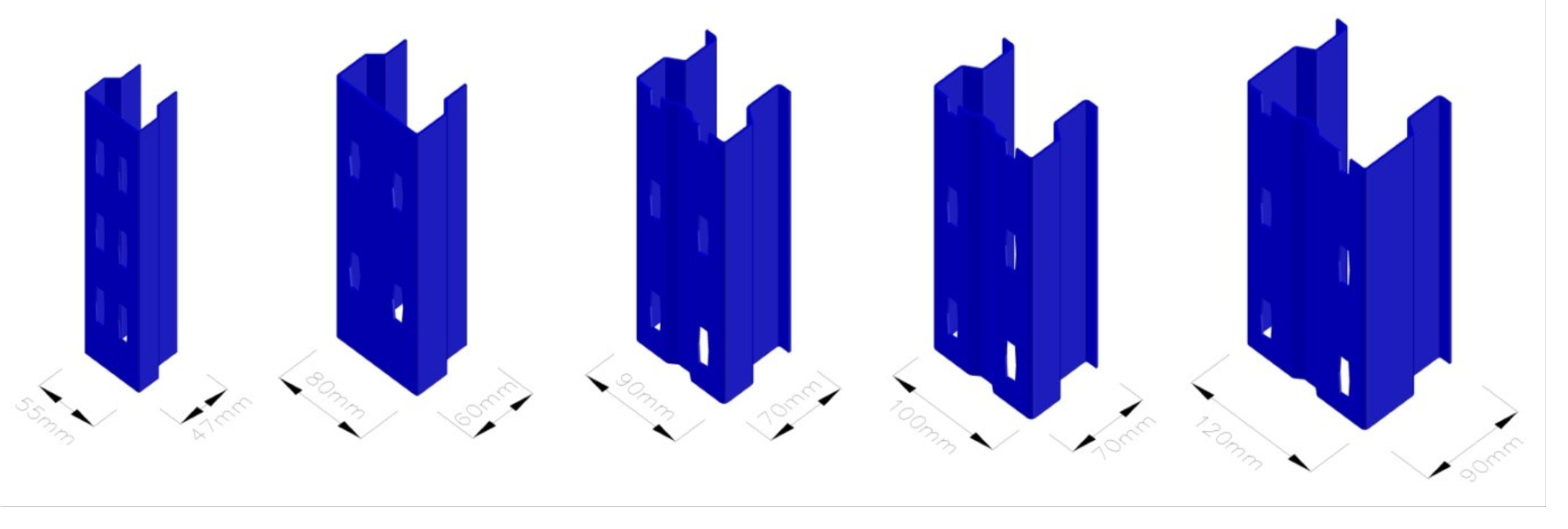

3.2 Iinkcukacha ezithe tye

4.Inkcukacha yokuvelisa ye-rack ekhethiweyo

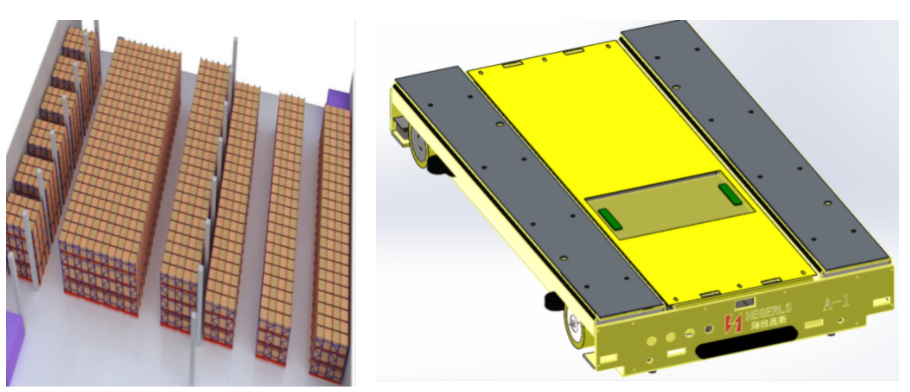

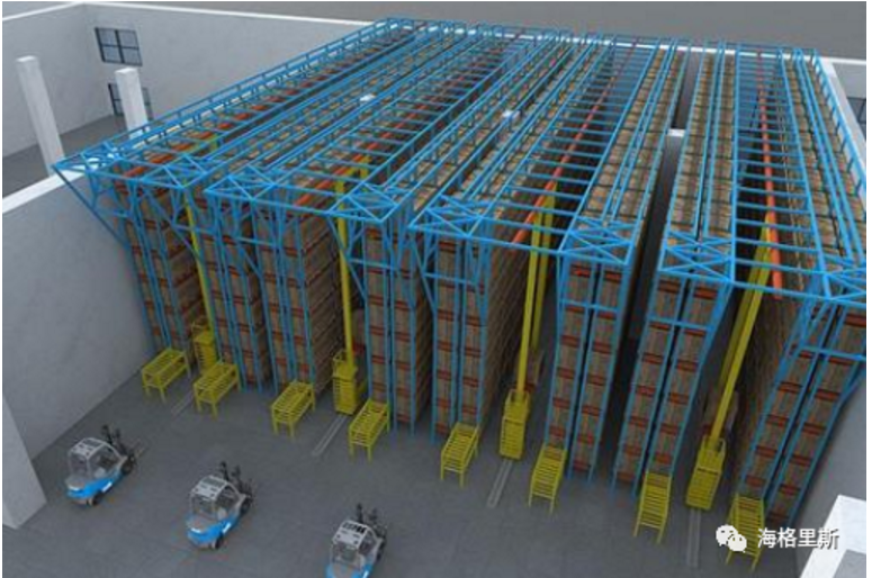

4.1Isistim yogcino oluxineneyo kakhulu ukugcina iipalethi, ukusetyenziswa kakuhle kwendawo yokugcina impahla;

4.2Inkqubo yofikelelo yokuqala-yokugqibela;

4.3 I-top and back bracing isetyenziselwa ukulungisa i-racking yonke, ukwenza yonke i-racking iqine kwaye ikhuselekile;

4.4Iipaliti zenqanaba lokuqala zinokubekwa kumgangatho ophantsi

4.5 Ukuguquguquka kunye nokulula kofakelo, ukuphucula ukusetyenziswa kwendawo.

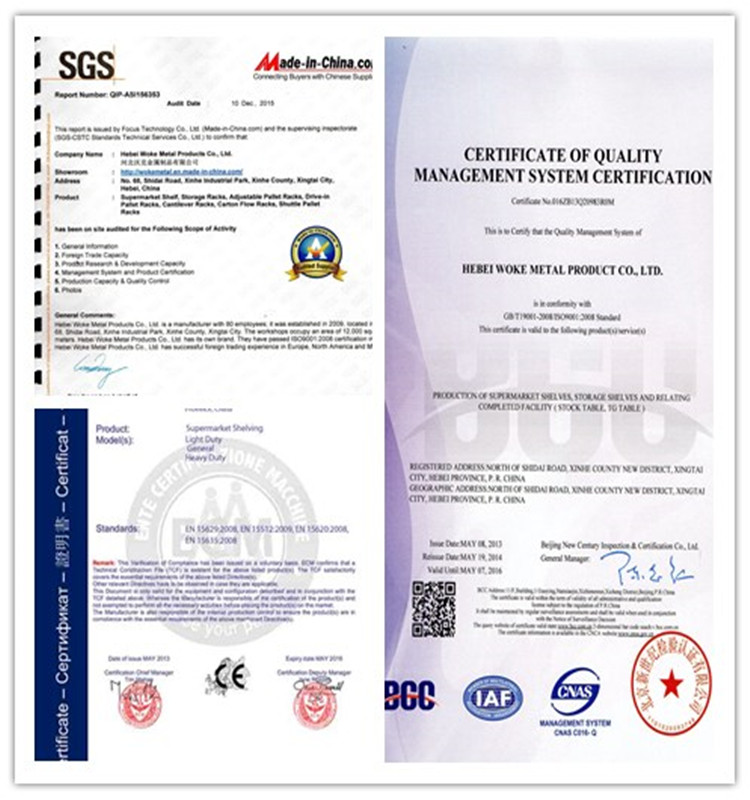

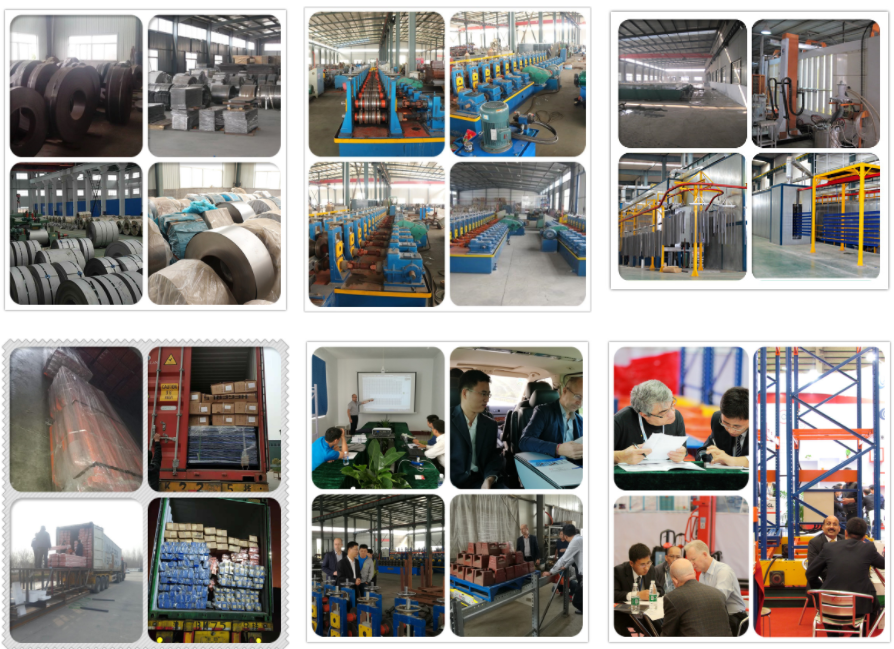

5.1 siphumelele isatifikethi se-SGS.BV, TUV kunye nesatifikethi solawulo lomgangatho we-ISO.

Ngaphaya koko, sikwapasile nesiqinisekiso solawulo lwendalo esingqongileyo, impilo nolawulo lokhuseleko

5.2 Izinto eziluhlaza: intsimbi eqengqelekayo ebandayo Q235B. okanye umgangatho wentsimbi wamazwe ngamazwe we-SS400

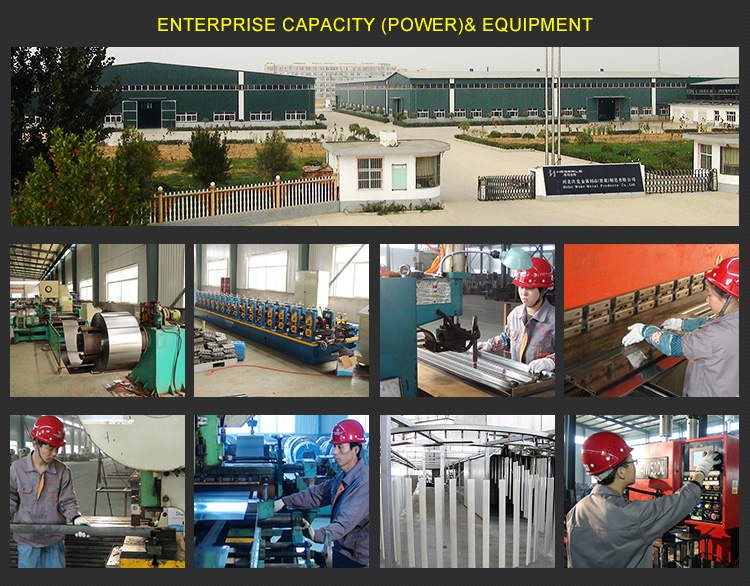

5.3. umatshini wokuqengqeleka. Sineseti ezili-12 eziqengqelekayo, ezinokuqengqeleka ngobungakanani obahlukeneyo.

5.4 Umgca wokugquma amandla. Imalunga neemitha ezingama-500 ubude kwaye uphawu lompu wokugquma amandla yiGEMA, edume kakhulu kwindawo yokugquma.

5.5 ukutyelela umthengi. Indawo yethu ikwiphondo le-hebei, kufutshane naseBeijing naseTianjin. Igama lethu lesikhululo seenqwelomoya yiShijiazhuang zhengding yesikhululo seenqwelomoya samazwe ngamazwe. Wamkele utyelelo lwakho nangaliphi na ixesha.

5.6 umboniso. Rhoqo ngonyaka siyakuzimasa i-canton fair kunye ne-shanghai Cemat fair.

Ukuhanjiswa. Ukuthumela ngenqanawa kunye nenkonzo

6.1 Ipakishwe kunye nokuthunyelwa. Ngokuqhelekileyo, abathe tye baya kupakishwa ngamagwebu eplastiki. Kwaye i-shuttle racking iya kulayishwa kwiipalati zokhuni.

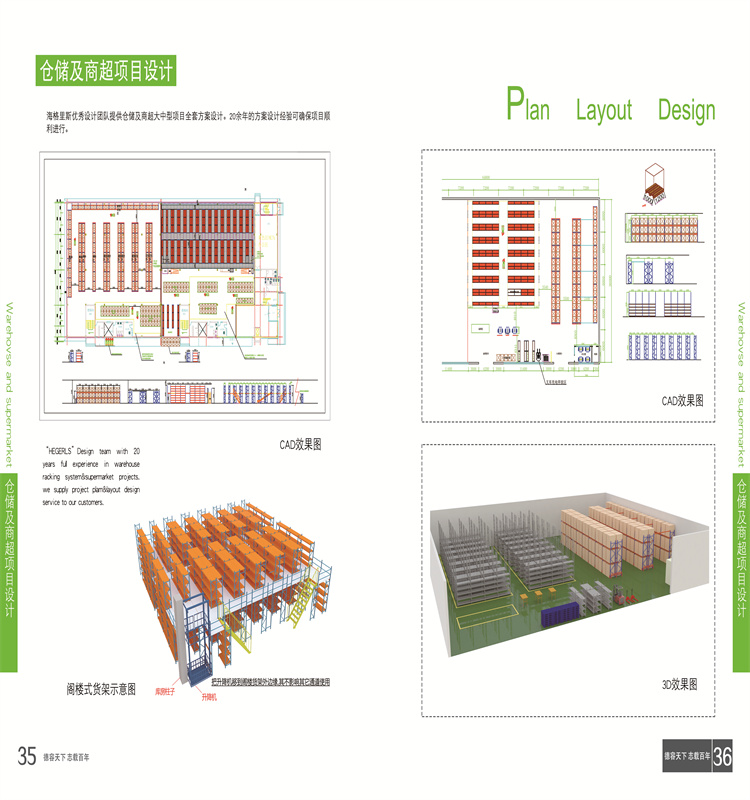

6.2 Sibonelela ngomzobo woyilo kunye nomfanekiso wesiphumo se-3d

FAQ

Q: Yintoni iwaranti yomgangatho weemveliso zakho?

A: Iwaranti yethu yomgangatho yiminyaka eyi-1. Siza kuqhubeka nokubonelela ngenkonzo ngaphandle kweli xesha kwaye sinikezela ngeendleko zamalungu asetyenzisiweyo kuphela.

Umbuzo: Liliphi ixesha lokuhamba?

A: Kwinkqubo yokurhangqa, ngokuqhelekileyo kuthatha iintsuku ezingama-30. Kwaye kwi-shuttle racking, idinga iintsuku ezingama-60 zemveliso.

Umbuzo: Ngaba ungabonelela ngoyilo loyilo?

A: Ewe, sinokubonelela ngoyilo loyilo ngokukhululekileyo kwi-Autocad okanye umfanekiso we-3d. Yinkonzo yethu yasimahla.

Umbuzo:Nguwuphi umbala obandayo okhoyo?

A: Ngokuqhelekileyo, sinemibala eluhlaza RAL5005 kunye ne-orange RAL2004. Umbala unokwenziwa ngokwezifiso. Nceda usinike inombolo yakho yombala.

Q: njani malunga nofakelo?

A: Siza kubonelela ngomzobo wofakelo oluneenkcukacha. Ukwenzela irakhi eqhelekileyo, abasebenzi banokuyifaka ngokomzobo wethu. Okanye, injineli yethu inokuya kwindawo ukuyalela ukufakela Kwaye umthengi uya kuhlawula iindleko.

Iindaba zamva

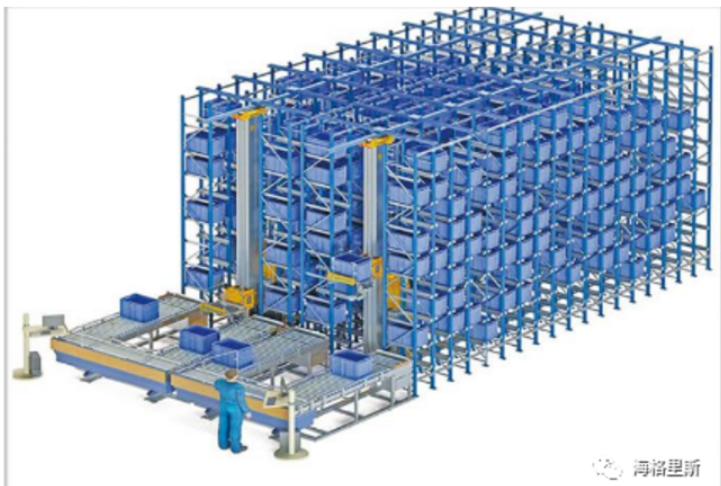

Isixhobo esingundoqo se-automated warehouse-stacker

I-crane yokupakishwa kwendlela elandelwayo yikhreyini ekhethekileyo ephuhliswe ngenkangeleko yendawo yogcino-ntathu, ekubhekiselwa kuyo njenge-stacker, sisixhobo esibaluleke kakhulu sokuphakamisa kunye nokuphatha kwindawo yokugcina izinto ezintathu, kwaye luphawu lweempawu zesithathu. -warehouse enemilinganiselo. Injongo yayo ephambili kukuqhuba ecaleni komzila kwindlela yendawo yokugcina impahla ephakamileyo yokugcina iimpahla ekungeneni kwendlela yokungenisa impahla; okanye ukukhupha iimpahla kwindawo yempahla kwaye uzithuthele ekungeneni kwendlela ukuze ugqibezele umsebenzi wogcino.

Kukho iintlobo ezininzi ze-cranes stacker. Kwizicelo zangoku ze-warehouse ezine-dimensional ezintathu, eyona ixhaphakileyo yile

1. Ngokwesakhiwo, ihlukaniswe ibe yintsika enye kunye nesakhiwo sekholamu ephindwe kabini

2. Ngokohlelo lomzila obalekayo, lohlulwe lwaba ludidi lomgca kunye nohlobo olugobileyo

Kungakhathaliseki ukuba luhlobo luni lwe-crane ye-stacker ngokubanzi iqulunqwe yindlela yokuhamba ethe tye, indlela yokunyusa, iqonga lokulayisha kunye nefolokhwe, isakhelo kunye nezixhobo zombane kunye nezinye iindawo ezisisiseko. I-motor ehambayo iqhuba amavili ukuba ahambe ngokuthe tye kumzila ongaphantsi kwi-drive shaft, i-motor yokuphakamisa iqhubela iqonga lomthwalo ukuba lihambe ngokuthe nkqo kwikhonkco / intambo yocingo / ibhanti, kunye neefolokhwe kwiqonga lomthwalo zenza intshukumo yeteleskophu. Umfumani wedilesi yokuhamba usetyenziswa Lawula indawo yokuhamba ethe tyaba ye-stacker, kwaye uphakamise umfumani wedilesi ukulawula indawo yokuphakamisa iqonga lokulayisha; ngokusebenzisa idilesi yokufumana idilesi kunye nokuqaphela i-photoelectric, kunye nokuguqulwa kwamanani onxibelelwano, ulawulo lwekhompyutheni lunokufezekiswa, kwaye ngokuzenzekelayo, i-semi-automatic kunye ne-manual control inokufezekiswa kwakhona ngepaneli yokulawula.

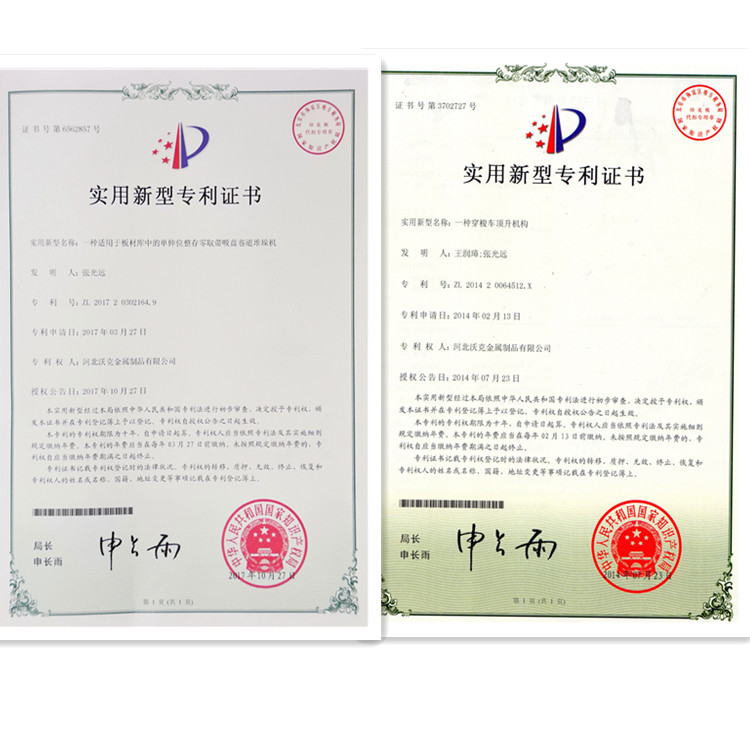

Sithethanje, kwiindawo zokugcina iimpahla zelizwe lam ezinemigangatho emithathu, ii-stackers zisetyenziswa kakhulu kwimizi-mveliso efana neyokwenza oomatshini, ukwenza iimoto, ishishini lamalaphu, oololiwe, icuba namayeza. Ngophuhliso lwemveliso yemizi-mveliso yanamhlanje, itekhnoloji yeekhranethi ezilandelwayo zendlela zihlala ziphucuka kwaye zigqibelele. Ukusukela ngo-2017, i-Hegerls ifumene imo entsha kunye ne-patent entsha yomsebenzi we-stacker. Iqhubekile nokushwankathela amava kwaye izibophelele kuphuhliso kunye nokusebenza. Besizimisele kakhulu ngokwakha indawo yokugcina impahla enemigangatho emithathu yeemveliso ezintsha ngokhuseleko nokhuseleko!

izixhobo zobugcisa.

Ukupakishwa kunye nokulayisha

Indawo yokubonisa

Undwendwelo lwabathengi

Uyilo loMzobo wasimahla kunye nomfanekiso we3D

Isatifikethi kunye namalungelo awodwa omenzi wechiza

Iwaranti

Ngokuqhelekileyo iba ngunyaka omnye. Inokwandiswa kwakhona.