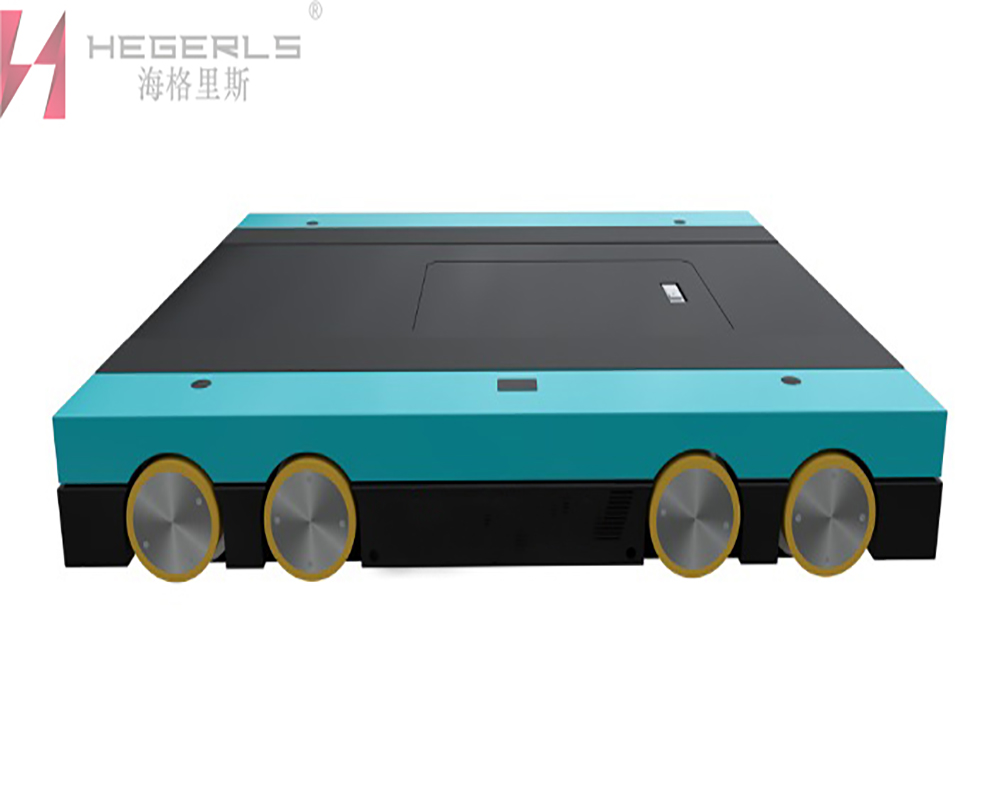

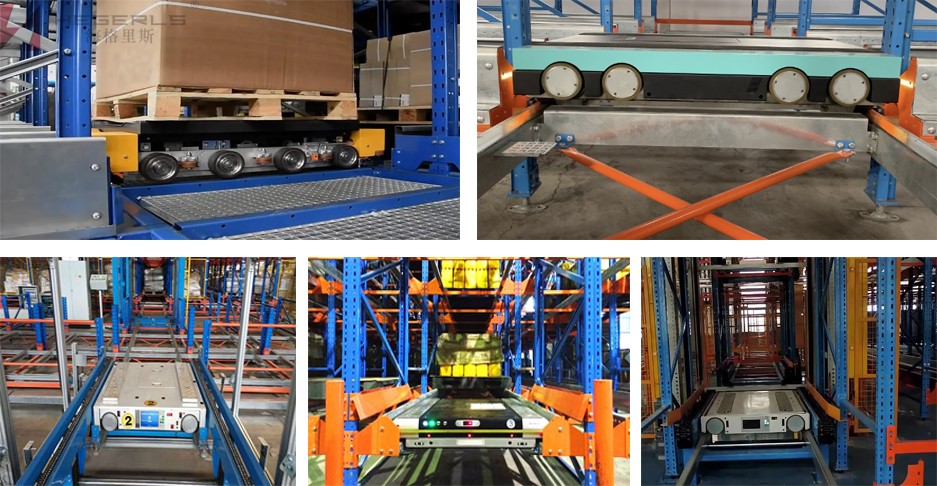

I-HEGERLS pallet ye-4-way shuttle car stereoscopic warehouse sisixhobo sothutho esilumkileyo esidibanisa imisebenzi emininzi efana nokuqhuba iindlela ezine, ukulandelela utshintsho kwindawo, ukuthutha ngokuzenzekelayo, ukubeka iliso okuhlakaniphile, kunye nokulawulwa kwe-traffic dynamic.Eyaziwa ngokuba yi-AGV, inokucwangciswa ukuba yenze imisebenzi efana nokuthatha, ukuthutha, kunye nokubeka iimpahla kwindawo yokugcina impahla, kwaye inokunxibelelana nenkqubo yokulawula indawo yokugcina impahla (WCS), ngokudibanisa nenkqubo yolawulo lwendlu yokugcina impahla (WMS), Itekhnoloji yolwazi lweRFID Logistics efana nokuqatshelwa kwebhakhowudi yenza ukuba iimpahla zichongwe, ufikelelo olunye, ufikelelo oluqhubekayo, ukubala okuzenzekelayo, kunye neminye imisebenzi.Iqhagamshelwe kulawulo olukude olungenazingcingo kwaye idibanisa itekhnoloji yokuchonga efana ne-RFID kunye nekhowudi ye-QR ukuqonda ngokulula ukuchongwa okuzenzekelayo kunye nokufikelela kwempahla kwiishelufu.

Ngokweemfuno zomsebenzi, i-pallet ye-4-way shuttle iloli isebenzisana ne-elevator ebuyiselayo ukugqiba imisebenzi yokusebenza kwimigangatho eyahlukeneyo yeshelufu kunye neendlela ezahlukeneyo zemithwalo ngokusebenzisa iileyili zokuhamba.Ngaphantsi kolawulo kunye nokucwangciswa kwenkqubo yokubeka iliso yendawo yokugcina impahla, yonke indawo yokugcina impahla exineneyo inokufezekisa ukusebenza ngaxeshanye kweeleya ezininzi kunye nezithuthi.Imoto eneendlela ezine zokuthutha inemisebenzi yokusebenza yokugcina ubuninzi kunye nokuhoxiswa, ukuhanjiswa kwempahla, ukubala i-pallet, njl., Ukufezekisa ukuhanjiswa kwezinto ngokukhawuleza kunye nokulawulwa kwe-inventory.Ingaphakathi layo lixhotyiswe ngomsebenzi wokuphepha umqobo kunye nomsebenzi we-alarm prompt function, onokunika ukhuseleko lokhuseleko kunye nengxelo ngexesha elifanelekileyo lolwazi oluphosakeleyo.

Umgaqo-nkqubo wokusebenza we-Hercules HEGERLS pallet ezine-wayway-way-shuttle inventory kukubeka i-Hercules HEGERLS i-pallet ye-four-way-shuttle-way kwi-rack track phantsi kwe-pallet, phantsi kwesikhokelo senkqubo ye-WCS, kunye neqonga lokuphakamisa i-shuttle ujonge phezulu, phakamisa iyunithi yephalethi ukubaleka ukuya kwindawo oya kuyo, uze ugcine iimpahla kwiphalethi kwindawo yomthwalo.

I-HEGERLS pallet ye-4-way shuttle inokusombulula ezi ntlungu zilandelayo kumashishini:

Inqaku le-Pain 1: Ukuphucula ukuguquguquka kokugcinwa

Uyilo lwemodyuli kunye nokuphunyezwa kwetreyi ye-HEGERLS yendlela emine yemoto ye-shuttle ye-stereoscopic warehouse system inika isuphamakethe yayo ngokuguquguquka.Phakathi kwazo, i-hardware enjengeemoto ezine-indlela ezine ezikrelekrele kunye ne-high-speed hoists zineenketho ezininzi, ezingafanelanga kuphela ukucwangciswa kwendawo enzima, kodwa kunye nokuguquguquka okuphezulu kwendawo enokuthi ivumelane neemeko ezahlukeneyo zoshishino, nazo. iphucula ukuguquguquka kwendawo.Ukongeza, inkqubo ekrelekrele yenza uhlalutyo lokuphunyezwa kwemeko yokusebenza kwaye isasaze ngokulinganayo imisebenzi yemisebenzi ukuqinisekisa ukucwangciswa okukrelekrele kwezixhobo ezininzi kunye nemisebenzi.

Inqaku le-Pain 2: Ukwandiswa kweSakhono sokuGcina

Indlela emine yogcino lwemoto ye-shuttle stereoscopic ijolise ikakhulu kwimeko yokusebenza yogcino oluxineneyo lwepallet stereoscopic yokugcina, enokuphucula umthamo wogcino kunye nesantya sokusebenzisa indawo kwindawo yokugcina, kunye nomlinganiselo wayo wevolumetric unokuba phezulu ukuya kuma-40% ukuya kwi-60%, ephinda ibe ngamaxesha angama-4-6 umlinganiselo we-volumetric we-flat storage kunye ne-1.3-2 amaxesha e-volumetric ratio ye-stacker yokugcina i-stereoscopic.Ngaphezu koko, ukufikelela kwi-elevator ye-speed-speed exhotywe kwi-warehouse ye-three-dimensional ye-pallet ezine-way-shuttle truck inokusebenzisa ngokupheleleyo ukuphakama kwendawo yokugcina impahla;Ukuncitshiswa kwemijelo yokusebenza nokusebenza ngokungenamntu noomatshini bezixhobo ezikrelekrele nako kunokunciphisa ngokusebenzayo inkunkuma yendawo yokudlula yezixhobo.

Inqaku le-Pain 3: Ukuphucula ukusebenza kakuhle koGcino

I-Hagrid HEGERLS inkqubo ye-tray ye-shuttle yendlela emine inokucwangcisa ngokufanelekileyo izixhobo zokulinda ezisekelwe kwimiyalelo, ngaloo ndlela inciphisa ixesha lokuqalisa kwesixhobo kunye nokuphucula ukusebenza kakuhle okungenayo kunye nokuphumayo ngaphezu kwe-30% xa kuthelekiswa ne-stacker.Xa kuthelekiswa nemisebenzi yezandla yemveli, i-pallet-way four-way shuttle vehicle ye-warehouse system ene-dimensional three-dimensional warehouse system inokunciphisa umsebenzi olula kunye nophindaphindayo wokuya nokubuya kwezandla ngexesha lenkqubo yokugcina impahla ngokusebenzisana ngokufanelekileyo kwezixhobo ezininzi ezikrelekrele kwindawo yokugcina impahla, ngaloo ndlela iphumeza ingenamntu. ulawulo lweshishini logcino kunye nokuphucula izinga lokusebenza kwangaphakathi kwendawo yokugcina impahla.Ngelo xesha, u-Hebei Walker uya kuqhubeka nokwandisa ukhetho lwendlela kunye nokucwangcisa i-algorithms yenkqubo yokusebenza yesofthiwe kwiimveliso eziphantsi kwe-HEGERLS brand ye-Haigris.Oku akunako nje ukukhuthaza ukwanda okubonakalayo kwisantya sokusetyenziswa kwesixhobo esinye, kodwa kunokufikelela kwintsebenziswano ekrelekrele yesoftware kunye nehardware kunye nomsebenzi wokusebenzisana wezixhobo ezininzi.Xa kuthelekiswa nomsebenzi wezandla wendabuko, ukusebenza kakuhle kwendawo yokugcina impahla kuye kwaphuculwa ngamaxesha angama-2-3.

I-Pain Point 4: Ukuphucula uMgangatho weMveliso

Uninzi lwamashishini kufuneka aqonde ukuba kwishishini langoku, uninzi lwamashishini luya kwamkela umgangatho kunye nokuvavanywa kokusebenza kwamacandelo ezixhobo ngexesha lokuphunyezwa kweprojekthi kunye nokugqitywa, kodwa i-drawback kukuba iindidi ezigutyungelwe ngexesha lokucwangciswa kwendawo ngokusekelwe kwiimfuno zeprojekthi zilinganiselwe.I-Hagrid HEGERLS i-tray ye-tray-four-way shuttle i-tray-dimensional ilayibrari inkqubo yethala leencwadi iya kukhokela ekugqibezeleni uvavanyo oluphindaphindiweyo lwemodyuli ngexesha loyilo kunye nokuhlolwa kwefektri, ukuqinisekisa ukuba ukuchithwa kunye nokuvavanya iiparitha ezahlukeneyo zemodyuli zinokwenziwa. kwiindawo ngeendawo eziphakamileyo kakhulu kunokuba kunokwenzeka ngexesha lenkqubo yokuphunyezwa kweprojekthi, ngokubonelela ngomgangatho ophezulu wokuhanjiswa kwesoftware kunye neemodyuli zehardware.

I-Pain Point 5: Ukunciphisa Iindleko zoTyalo-mali

Uyilo olusemgangathweni kunye nemodyuli ye-Higgris HEGERLS yetreyi ye-4-way-shuttle isithuthi se-three-dimensional system inokuqinisekisa ngokuchanekileyo ngakumbi ukuba ukwakhiwa kwendawo yokugcina isithuthi esinengqiqo ezintathu-dimensional warehouse ingatyalwa kwizigaba ezisekelwe kwimfuno ye-output yoqobo yokugcina, kunye ne umthamo omkhulu ukuze kuhlangatyezwane neyona mfuno, kuthotywe ngempumelelo iindleko zokulingwa kunye neempazamo zotshintsho olukrelekrele lweshishini kunye neendleko zotyalo-mali zenqanaba lamva leprojekthi, kunye nokufezekisa imbuyekezo yotyalo-mali ngokukhawuleza.Ukongeza, uyilo lwemodyuli ye-hardware kwi-HEGERLS itreyi ye-4-way-shuttle ye-shuttle ye-three-dimensional warehouse system inokuphumeza imisebenzi engabhalwanga kwindawo yokugcina.Le ndlela yokusebenza inokunciphisa iindleko zokusebenza kwi-warehouse, iyancipha ngaphezu kwe-50% xa kuthelekiswa nokusebenza ngesandla.

Inqaku le-Pain 6: Ukuhanjiswa ngokukhawuleza

Emva koyilo oludityanisiweyo oluphezulu kunye nokuphunyezwa kwemveliso yeemodyuli ze-HEGERLS, ukuhanjiswa ngokufanelekileyo kohlobo lwetreyi yesithuthi esinendlela emine yothutho lwethala leencwadi elinamacala amathathu liya kuphuculwa kakhulu.Uyilo lwesikimu seprojekthi yogcino lusebenzisa inkqubo ye-Hebei Walker ekrelekrele yogcino lwezixhobo ukuphumeza uyilo olukrelekrele, kunye neplagi yesixhobo semodyuli kunye nokudlala, okwenza intsebenziswano ekrelekrele yezixhobo ezininzi kunye nemisebenzi ngaphandle kokulungiswa ngokuphindaphindiweyo.Utshintsho kunye nokuphuculwa kweeprojekthi zogcino lunokusasazwa ngokufanelekileyo kwiintsuku ezingama-20 ukuya kwezingama-40, ngaloo ndlela kufezekiswa i-100% yonikezelo lomgangatho ophezulu weeprojekthi zogcino ngaphandle kokwenzeka kweeprojekthi ezingagqitywanga.

Ixesha lokuposa: Mar-23-2023