Njengoko / rs (ukugcinwa okuzenzekelayo kunye nenkqubo yokubuyisela) iqulunqwe ngokukodwa ngamashalofu amanqanaba amathathu aphezulu, izitaki zendlela, oomatshini bokuphatha umhlaba kunye nezinye izixhobo ze-hardware, kunye nolawulo lwekhompyutheni kunye nenkqubo yokubeka iliso.Ngenxa yezinga eliphezulu lokusetyenziswa kwendawo, amandla angaphakathi nangaphandle anamandla, kunye nokusetyenziswa kweekhomputha ukulawula nokulawula, okulungele ukuphunyezwa kolawulo lwangoku, iye yaba buchwephesha obuyimfuneko bokugcinwa kwempahla yeshishini kunye nolawulo lwemveliso, kwaye iye yabangela ukuba kube nzima ukujongana nolawulo lwezobuchwephesha. inikwe ingqwalasela eyongezelelekileyo ngamashishini.Ke luhlobo luni lwenkqubo yobukrelekrele yinkqubo ye as/rs ye-automated warehouse ene-dimensional three-dimensional, kwaye iwanceda njani amashishini ukuba enze ulawulo lomsebenzi kunye nesenzo?Ngoku vumela umenzi weshelufu yokugcina i-hegerls ye-hagris akuhlalulele yona!

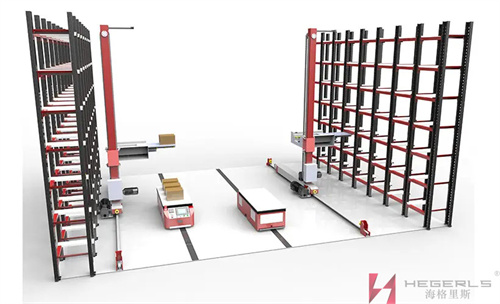

Ubukrelekrele njenge/rs yimodyuli ekrelekrele eyongezwe kwisiseko semveli njenge/rs.Kwinkqubo yokucwangciswa komsebenzi, ulwabiwo lwendawo kunye nokulungiswa komgca, ngokomgaqo wokucwangciswa komsebenzi, isicwangciso sokwabiwa kwendawo, iinjongo zokuphucula umgca kunye nezithintelo ezihambelanayo, kunye nokuseka imodeli yedatha ehambelanayo, sebenzisa i-algorithm ehlakaniphile ukusombulula, ukufumana isisombululo esona sisombululo, kunye nokuphucula ukusebenza kakuhle kwenkqubo yokugcina impahla enemigangatho emithathu.

Ukuqulunqwa kwenkqubo njenge/rs

Isitora esizihambelayo esinemigangatho emithathu siqulunqwe ikakhulu yinkqubo yokugcina imathiriyeli, njenge/rs inkqubo yokugcina, njengolawulo kunye nenkqubo yokubeka iliso.

1) Inkqubo yokugcina izinto eziphathekayo

Iqulethwe yimpahla ye-cargo ye-shelf ye-three-dimensional kunye nesixhobo sokuphatha izinto (ukupakishwa kwezinto eziphathekayo, i-pallet, ibhokisi ye-turnover, njl.).Izinto eziphathekayo zibekwe rhoqo kwaye zigcinwe ngokucocekileyo kwisixhobo esithwala izinto eziphathekayo, kwaye isixhobo esithwala izinto sigcinwa kwigridi yempahla, senza inkqubo yokugcina egqityiweyo.

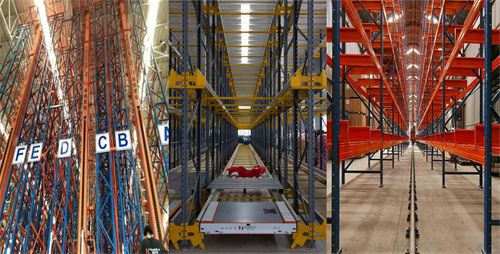

2) Njenge/rs inkqubo yokugcina impahla

Inkqubo yenza imisebenzi yokufikelela kwempahla kunye nokungena nokuphuma kwindawo yokugcina impahla.Idla ngokuqulunqwa zizitaki zendlela, umhambisi ongenayo kunye nophumayo, oomatshini bokulayisha kunye nokukhulula, njl. njl.Iyakwazi ukuqonda iintshukumo ezintathu: ukuhamba ecaleni kwendlela, ukunduluka ngokuthe nkqo kunye nokumisa, kunye nokwandiswa kwefolokhwe kunye nokucutheka.Isetyenziselwa ukugcina ngokuzenzekelayo okanye ukukhupha iimpahla kuyo nayiphi na indawo yempahla kumacala omabini eeshelufu.Ngokweempawu zempahla, abahambisi bempahla bangaphakathi nangaphandle banokuthatha i-conveyors ibhanti, abahambisi be-roller, i-chain drive conveyors, njl. njl., ezithumela ubukhulu becala iimpahla kwindawo yokupakisha kunye nokukhulula kunye nempahla ngaphakathi nangaphandle kwendawo yokugcina. .Ukulayishwa kunye nokukhulula oomatshini benza umsebenzi wokulayisha okanye ukukhulula iimpahla ngaphakathi nangaphandle kwendawo yokugcina impahla.Ngokuqhelekileyo yenziwe ngeekhreyini, iikhreyini, iiforklift kunye nabanye oomatshini.

3) Njenge/rs inkqubo yolawulo kunye nokubeka iliso

Iqulunqwe yikhompyuter yeklayenti, ikhompyuter yolawulo oluphakathi kunye nenkqubo yolawulo lombane.Ulawulo lwe-as/rs kunye nenkqubo yokubeka iliso ayilawuleki kuphela kwaye ihlalutye ulwazi lwemathiriyeli, ubume bogcino kunye nelog yokusebenza kwendawo yokugcina impahla yendawo yokugcina impahla enamacala amathathu, kodwa ikwabeka iliso ngexesha lokwenyani lemeko yokusebenza kwendawo yokugcina izinto ezintathu-ntathu kunye neeshedyuli zangexesha ezinokulungiseka. izibonelelo zendawo yokugcina impahla enemigangatho emithathu.

Ubukrelekrele njenge/rs ubume benkqubo kunye nenkqubo

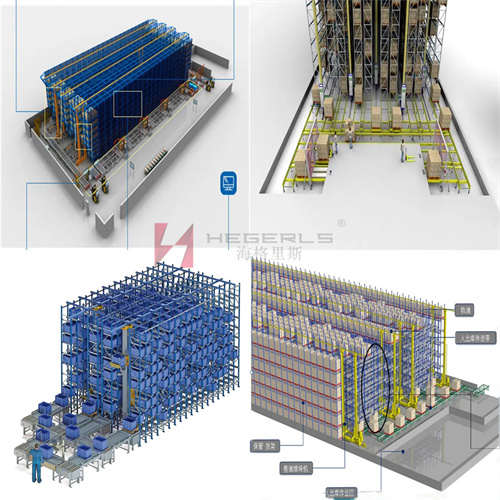

1) Uyilo lwenkqubo

Ugcino oluzenzekelayo olunemigangatho emithathu yinkqubo ebanzi edibanisa izinto zokusebenza, ulawulo kunye noqeqesho lwekhompyutha.Iindlela zokusetyenziswa kwe-automated three-dimensional warehouse management and monitoring system inokwahlulwa ibe kwindawo enye, yahlulwe kwaye isasazwe.Okwangoku, iiprojekthi ezininzi ehlabathini zisebenzisa iinkqubo ezisasazwayo.

I-Wmos (ulawulo lwe-warehouse kunye nenkqubo yokusebenza) i-architecture idla ngokwahlulahlulwe yangamacandelo amane: umaleko wesicelo, umaleko wenkonzo, umaleko wolawulo kunye nezixhobo zokusebenza.Ukususela kumgangatho wokusebenza, inkqubo yogcino lwe-automated ye-three-dimensional ingahlulwa ibe ngamanqanaba amathathu: inqanaba lolawulo, inqanaba lokuhlola kunye nenqanaba lokwenziwa.

Ulawulo: yinkqubo yolawulo lwekhompyutha, enemisebenzi yokumisela inkqubo, ukugcinwa kolwazi lwenkqubo, ukugcinwa kolwazi lwemveliso, ishishini lokugcina impahla, iinkcukacha-manani zombuzo we-inventri, njl. njl. ukuphatha iimpazamo, njl. yendawo yokugcina impahla enemigangatho emithathu.

Umaleko wokubek' iliso: yinxalenye ebalulekileyo yenkqubo yokugcina impahla enemigangatho emithathu.Ilawula izixhobo zokusebenza ngokwemiyalelo evela kubaphathi kwaye igqibezele imisebenzi ehanjiswa ngabaphathi;Ngakolunye uhlangothi, umaleko wokubeka iliso ubume be-stacker ngexesha langempela ngendlela ye-animation, kwaye ubuyisela ulwazi lwangoku lwe-stacker kubaphathi, ukubonelela ngokubhekisele kwiinjineli ukucwangcisa imisebenzi.

Umaleko oLawulayo: yenziwe nge-stacker efakwe kwi-PLC.I-PLC kwi-stacker ifumana imiyalelo evela kuluhlu lokubeka iliso kwaye yenza imisebenzi eyahlukeneyo ngokwemiyalelo.

Ngapha koko, kunokubonwa ukuba ulawulo lusisiseko sobukrelekrele njenge / rs, kwaye ukuqonda kwayo ngobukrelekrele kubonakaliswa ikakhulu kwiimodyuli ezine ezibalulekileyo: imodyuli yesabelo esikrelekrele semisebenzi yomsebenzi, imodyuli yokucwangcisa ekrelekrele yokuhanjiswa kwezinto, imodyuli yokuphucula ngobukrelekrele. umgca womsebenzi / umendo, kunye nemodyuli yokulungisa iimpazamo.Imodyuli nganye idlala indima eyahlukileyo kwiindidi ezahlukeneyo zeenkqubo zomsebenzi.

▷ imodyuli yesabelo esikrelekrele semisebenzi yokusebenza: ngokwemeko yokugcinwa kwezinto eziza kuhanjiswa kwaye zigcinwe kwiyunithi yogcino nganye, yabela ngokufanelekileyo imisebenzi yokuhanjiswa kunye nokugcinwa kwendawo yokugcina impahla, ukuze kulinganiswe umthwalo womsebenzi weyunithi nganye yokugcina kunye nokunciphisa ixesha lokulinda imisebenzi yokusebenza.

▷ Imodyuli yokuhanjiswa kwemathiriyeli ehlakaniphileyo: ngokokuphindaphinda kwezinto ngaphakathi nangaphandle kwendawo yokugcina impahla, iimpawu ezibonakalayo, imeko yangoku yokwabiwa kwendawo yokugcina impahla, njl. ukusebenza kakuhle kweyunithi yokugcina ngaphakathi nangaphandle kwendawo yokugcina impahla.

▷ Umgca womsebenzi / imodyuli yokuphucula ingqiqo: lungisa ukulandelelana komgca okanye indlela yomsebenzi we-stacker ngokwemilinganiselo yokusebenza yenkqubo yokugcina impahla, ukwenzela ukunciphisa ixesha lokusebenza kwe-stacker kunye nokuphucula ukusebenza kakuhle kokugcinwa.

▷ Imodyuli yokusetyenzwa ngabom: Le modyuli ikakhulu ijongana neziphene zokucwangcisa ezinengqondo, kuneziphene zoomatshini kunye neempazamo zonxibelelwano.Jongana nempazamo ngexesha kwaye ulandele oyena nobangela wempazamo.

Uyilo lwezobukrelekrele njenge/rs lwenziwe ngendlela ekrelekrele yokucwangcisa kunye ne/rs indlela yolawulo lwempahla.Indlela yokucwangcisa ekrelekrele ye-automated ye-warehouse enemigangatho emithathu kuqala imisela iskimu sokucwangcisa esisebenzayo ngokusebenzisa umgaqo wocazululo lwenkqubo yolawulo ngokwesikali, ulwakhiwo, indawo yokugcina impahla kunye nenkqubo yogcino lwenkqubo, isicwangciso solwabiwo lomsebenzi, ukuhanjiswa kwemathiriyeli kunye nesicwangciso sokusetyenzwa kunye olunye ulwazi lwendawo yokugcina impahla.Okwesibini, ngokweskimu sokucwangcisa esikrelekrele, inyathelo lokuqala kukwaba imisebenzi yemisebenzi ukusuka kwinqanaba elipheleleyo lendawo yokugcina impahla, kunye nokwabiwa kwendawo yokugcina iimpahla kunye nokugcina imisebenzi kwiiyunithi ezithile zokugcina;Isinyathelo sesibini kukubonelela ngeendawo zokugcina iiyunithi ezithile zokugcina;Isinyathelo sesithathu kukwandisa umgca womsebenzi webhetshi kwiyunithi yokugcina nganye ngokwesiphumo sokwabiwa kwendawo kwisinyathelo sangaphambili.Indlela yokucwangcisa ehlakaniphile yindlela yokucwangcisa esasazwayo, ukusuka kulwabiwo lomsebenzi wehlabathi ukuya kwindawo yokwabiwa kwendawo kunye nokulungiswa komgca weeyunithi ezithile zokugcina.

2) Inkqubo ephambili yenkqubo ekrelekrele njenge/rs

▷ inkqubo yokusebenza yangaphakathi nangaphandle: kwinkqubo yokusebenza yangaphakathi nangaphandle, ngokweenkcukacha zezixhobo eziza kugcinwa zirekhodwe kwitafile yedisk yedisk kunye neenkcukacha zezinto eziza kugcinwa kwi-odolo yokuhanjiswa, ukuhlalutya ukugcinwa kwendawo izinto ezihambelanayo kwi-warehouse ye-three-dimensional kwiyunithi yokugcina, kunye nokwabela imisebenzi kwiyunithi yokugcina.Emva kokuba iyunithi nganye yokugcina ifumane imisebenzi ehambelanayo yokuphuma kunye nokuphumayo, ngokuhambelana nokuhanjiswa kwezinto kwiyunithi yokugcina, imodyuli yokusabalalisa izinto ezihlakaniphileyo inika indawo efanelekileyo kumsebenzi ngamnye wokusebenza.Umgca womsebenzi / imodyuli yokwandisa ngobukrelekrele inika umba ophambili wemisebenzi yebhetshi elindele ukwenziwa kwiyunithi yokugcina.Imodyuli yokuphucula umgca inokwandisa umgca womsebenzi we-batch ngokweenjongo zokuphucula ukuphucula ukusebenza kakuhle kokugcinwa.

▷ inkqubo yokubala: into ebizwa ngokubala ibhekisa ekubaleni ukufumanisa elona nani lichanekileyo, umgangatho womgangatho kunye nemo yogcino lwemathiriyeli ekhoyo okanye imveliso kwindawo yokugcina impahla.Yinkqubo yolawulo lwengxelo yolawulo lwezinto.Imo yokusebenza yokubala ibandakanya ukubala kwehlabathi kunye nokubala okungacwangciswanga.I-inventri yehlabathi ineempawu zomlinganiselo omkhulu we-inventri, umjikelo we-inventri omde, ukusetyenziswa kwezixhobo kwi-inventri enye, kunye nefuthe kwimveliso.I-inventri engaqhelekanga ineempawu zomlinganiselo omncinci we-inventory, umjikelo omfutshane woluhlu, usetyenziso oluncinci lwezixhobo kunye nempembelelo encinci kwi-inventory enye.Ngokujonga iimpawu ze-inventory random, i-inventory engabonakaliyo ingabalwa ngamaxesha amaninzi ngokobukhulu be-inventory, ukwenzela ukuba kuphuculwe izinga lokusetyenziswa ngokufanelekileyo kwendawo yokugcina kunye nokuhambelana kwedatha yokugcina.Xa ingxelo eneenkcukacha zezinto eziphathekayo ibalwa ekupheleni konyaka, kufuneka uluhlu lwehlabathi jikelele lwendawo yokugcina impahla.Inkqubo yokubala ibandakanya isebe lokubonelela ngezinto eziphathekayo, isebe lemveliso, isebe lokulawula indawo yokugcina impahla, isebe lokuthengisa kunye namanye amasebe amaninzi, ngoko inokuphucula ukusebenza kakuhle kokubala, ukugcina ixesha lokubala kunye nokunciphisa impembelelo kwimveliso.

▷ inkqubo yokusebenza yokudluliselwa kwempahla: ugxininiso lomsebenzi wokudluliselwa kwempahla kukucoca iindawo ezifuna ukuhanjiswa.Imodyuli yokuhanjiswa kwezinto ezikrelekrele igcina uhlobo olufanayo lwemathiriyeli kwindawo esembindini ngokweemfuno zokuxinana kwezixhobo, kwaye ikhetha indawo yokugcina impahla ekufuneka ihanjiswe.Emva kokumisela indawo yokugcina, ukulandelelana kokusebenza kwendawo yokugcina icaciswa ngokusebenzisa imodyuli yokuphucula indlela yokusebenza ukwenza ikhonkco elipheleleyo lokugcina, ukunciphisa ixesha lokungabikho komthwalo we-stacker kunye nokuphucula ukusebenza kakuhle.

Indawo yokugcina izinto ezenzekelayo yinkqubo ecacileyo, eguqukayo, yezinto ezininzi kunye nenkqubo entsonkothileyo eneenjongo ezininzi.Ulawulo olukrelekrele lwe-as/rs yingxaki yokuphucula inkqubo.Indlela yendabuko ayithathi nje ixesha elide kwaye ibiza kakhulu, kodwa kunzima ukufumana isisombululo esona sisombululo.Kule nkalo, umenzi weshelufu yokugcina i-Hergels udibanisa ithiyori yokuphucula ingqiqo kunye nesicelo se-s / rs, enokuphucula ukusetyenziswa kwendawo kunye nenqanaba lokulawula ukugcinwa, ukunciphisa ubuninzi bomsebenzi, ukuphucula inqanaba lokucwangcisa izinto, ukukhawulezisa ukuguqulwa kwemali yokugcina imali, kunye nokubonelela ngesiseko esisebenzayo. kumyalelo wemveliso kunye nokwenza izigqibo kumashishini.

Ixesha lokuposa: Aug-03-2022