Amashishini amaninzi aneendawo zawo zokugcina imveliso okanye iimpahla.Ukuze kuququzelelwe ulawulo kunye nokunyusa umthamo wokugcina iimpahla kwindawo yokugcina impahla, ezinye iimpahla ezinkulu kunye ezinzima zifuna iishelufu zokugcina ezinzima.Okukhona iphezulu ishelufu yokugcina enzima, kokukhona uphezulu izinga lokusetyenziswa kwendawo yokugcina impahla, kwaye kokukhona ngqongqo iimfuneko zeshelufu yokugcina enzima.

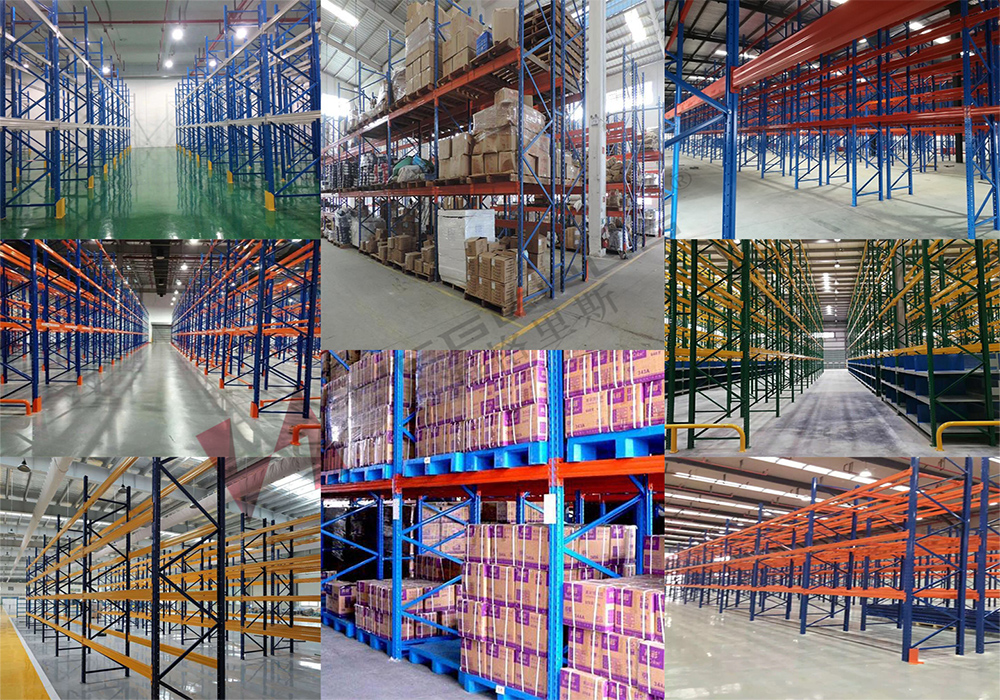

Iishelufu zokugcina ezinzima, ezikwaziwa ngokuba ziishelufu zohlobo lwe-beam, okanye iishelufu zodidi lwempahla, zezeshelufu zepallet, eziyindlela eqhelekileyo yeeshelufa kwiinkqubo ezahlukeneyo zogcino eTshayina.Isakhiwo esihlanganiswe ngokupheleleyo ngendlela yesiqhekeza yekholomu + i-boam ilula kwaye iyasebenza.Izincedisi ezisebenzayo ezifana ne-spacer, i-laminate yensimbi (i-laminate yokhuni), i-wire mesh layer, i-reil ye-cage yokugcina isikhokelo, i-oyile drum rack kunye nokunye oko kunokongezwa ngokweempawu zeyunithi yokugcina izixhobo ezigciniweyo.Dibana nogcino lweempahla kwiifom ezahlukeneyo zesixhobo esinezixhobo.Ngoko ke, ziziphi iingxaki ekufakweni kweeshelufu ze-Hebei ezinzima?Zeziphi “izingqinisiso ezithandathu” zeeshelufu ze-Hebei ezinzima ezisetyenziswayo?Ziziphi iimfuno zokulayisha kwiishelufu zokugcina ezinzima?Okulandelayo, i-haigris encinci ephothiweyo umenzi weshelufu uya kukuthatha ukuba uqonde.

Ziziphi iingxaki ekufakweni kweeshelufu ze-Hebei ezinzima?

1) Zonke iintlobo zokuqinisekiswa kwe-metrological kunye nezixhobo zokuhlola, izixhobo kunye nezixhobo, iipaneli zezixhobo kunye noomatshini kunye nezixhobo ezikhethiweyo kwiishelufu zihlangabezana neemfuno zokuqinisekiswa kwe-metrological standard.

2) Imisebenzi yokuhlobisa efihliweyo yeeshelufu ngaphambi kofakelo iya kuhlolwa ngaphambi kokuba iprojekthi ifihliwe kwaye inokwakhiwa kwakhona emva kokufikelela kumgangatho.

3) Lo mgangatho wenzelwe ukufakwa ngokubanzi kunye nokwamkelwa kobunjineli beeshelufu, ezifuna iishelufu kunye nokuphucula inzuzo yezoqoqosho.

4) Ukufakwa kwe-rack kuya kwenziwa ngokomzobo.Ukuba kukho nakuphi na ukungahambelani kufunyenwe ngexesha lokwakha, kuya kubekwa phambili ngokucacileyo.Ukwakhiwa kunokuqhutywa kuphela emva kokuba utshintsho luvunyiwe.

5) Ukuzihlola ngokwakho kuya kwenziwa ngexesha lofakelo lweshelufu.

Ngokukodwa kwindawo yokulawula, kubalulekile ukuthatha la manyathelo amathandathu okhuseleko kwiishelufu zokugcina ezinzima.Zeziphi “izingqinisiso ezithandathu” zeeshelufu ze-Hebei ezinzima ezisetyenziswayo?

I-1) Thintela i-top heavy: bambelela kumgaqo "wempahla elula phezulu kunye nempahla enzima ezantsi" xa usebenzisa.

2) Ukuthintela ukugqithiswa: ubunzima boluhlu ngalunye abuyi kudlula umthamo wokuthwala weeshelufu ezinzima.

3) Ukuthintela ukungqubana: ngexesha lokusebenza kwe-forklift, kufuneka iphathwe ngobumnene ukuze ugweme ukungqubana namashalofu.

4) Ukuthintela ukuma: xa kukho iimpahla ngaphezu kweshelufu, umqhubi akayi kungena ngokuthe ngqo ngaphantsi kweshelufu ukukhusela ukuwa ngengozi kwempahla kunye nokulimala.

5) Ukuthintela ukusetyenziswa kwezinto ezingezizo eziqhelekileyo: iibhodi zemigangatho ezingekho phantsi, iitreyi, njl. Azivumelekanga kwiishelufu ezinzima.

I-6) Ukuthintela i-pin yokukhusela ekuweni: ukuba i-pin yokhuseleko iyawa ngexesha lokusetyenziswa, i-boam iya kuwa, okanye ukufakela akuyi kubakho, kwaye i-shelf iya kulimala okanye yonzakala.

Okulandelayo, abavelisi beeshelufu ze-haigris bangathanda ukuthetha ngakumbi kumashishini amakhulu:

Umda womthwalo kunye nowona mthwalo uphezulu we-rack yokugcina enzima:

I-1) Ubuninzi bomthwalo wobunzima beyunithi yokulayisha i-pallet (kubandakanywa ne-pallet mass) evunyelwe ukuba iqhutywe ngumqolo ngamnye we-cross beam kwaye ikholomu nganye ibizwa ngokuba ngumthwalo ophezulu.Ubuninzi bomthwalo weshelufu ngumthwalo ophezulu ovumelekileyo weshelufu emva kokuqwalasela ukugqithisa kunye nezinye izinto.

2) Ubunzima beyunithi yokulayisha i-pallet (kubandakanywa nobunzima bepalethi) egcinwe ngokukhuselekileyo kwindawo nganye yomthwalo we-quota yokulayisha i-rack ibizwa ngokuba yi-quota loading.

Ukulayisha iimfuno zeeshelufu zokugcina ezinzima:

I-1) Umthwalo we-Dynamic ubhekisela kubunzima obukhulu obunokuthi buphakanyiswe kanye ngokusebenzisa i-forklift yombane okanye i-manual hydraulic pallet handling.Ngokubanzi, i-pallet yeshelufu inokuthwala i-1.5t-2t, i-pallet eqhelekileyo inokuthwala i-1t, kunye ne-ultra pallet ekhanyayo inokuthwala i-0.5T.

I-2) Umthwalo weshelufu ubhekisela kubunzima obuninzi obuvunyelwe xa iimpahla ezilayishwe kwiipalati zeplastiki zibekwe kwiishelufu.Kufuneka kuqwalaselwe umahluko phakathi komthwalo oguqukayo, umthwalo ongatshintshiyo, umthwalo weshelufu kunye nomthwalo othe nkqo wogcino.Umahluko wokuthwala umthamo uhambelana ngokusondeleyo nesakhiwo seshelufu, ubushushu be-ambient kunye nomjikelo wokugcina.Ngokuqhelekileyo, iipaliti ezinzima ziyakwazi ukumelana ne-0.7t-1t kwi-shelf crossbeam, ngelixa i-pallets eqhelekileyo inokumelana ne-0.4t-0.6t.

I-3) Ukulayishwa kweShelf kuneemfuno ezithile zokuguqulwa kwesigxina kunye nokuguquguquka kweepalati zeplastiki.Umgangatho wesizwe wokuguquguquka yi-30mm, kodwa oku ngokucacileyo kunomkhethe.Abavelisi beeshelufu ze-Hegris batusa ukusebenzisa iipaliti zeplastiki kunye ne-elasticity engekho ngaphezu kwe-20mm kwiishelufu.Ukuba yindlu yokugcina i-auto-dimensional three-dimensional, iimfuno zokuguquguquka zingqongqo, ngokubanzi ngaphakathi kwe-10mm.

I-4) Umthwalo we-static ubhekisela kubunzima obuninzi obunokuthi i-tray yeplastiki isezantsi ithwale xa ibeka.Iipalati zeshelufu eziqhelekileyo ziyakwazi ukumelana ne-6t-8t, iipallets eziqhelekileyo ziyakwazi ukumelana ne-4T, kunye ne-ultra light pallets zingakwazi ukumelana nomthwalo we-1t static.

Oku kungasentla kumxholo wanamhlanje.Ukuba usafuna ukwazi ngakumbi malunga neeshelufu ze-Hebei ezinzima, ungajongana nenkonzo yabathengi be-intanethi ye-Hagrid.Siya kukukhonza ngentliziyo epheleleyo.

Ixesha lokuposa: Sep-09-2022